The Cost of Domestic Textiles in Liaoning

: The Cost of Domestic Textiles in Liaoning,Abstract: This paper aims to explore the cost of domestic textiles in Liaoning Province, a significant economic region in China. By analyzing data on prices and production costs, we find that the cost of domestic textiles has increased significantly in recent years. This rise is primarily due to factors such as rising raw material prices, increased labor costs, and the impact of global trade policies. Additionally, the high demand for domestic textiles in Liaoning has driven up production costs, leading to higher prices for consumers. Despite these challenges, the industry remains competitive in the market, with many local manufacturers striving to maintain their positions by adopting innovative production methods and enhancing product quality. Overall, the study highlights the importance of understanding the cost implications of domestic textiles in Liaoning to support policymakers and businesses in making informed decisions about investment and production strategies.

Introduction: In the vast and diverse landscape of China, where the textile industry is a cornerstone of economic growth, the cost of domestic textiles in Liaoning, specifically the city of Dalian, stands out as a pivotal indicator of the region's competitiveness. This article delves into the intricate web of factors that contribute to the cost of domestic textiles in Liaoning, offering a comprehensive overview through an analysis of key variables such as raw material costs, labor expenses, transportation logistics, and market dynamics. By examining these elements, we aim to shed light on the complexities that shape the price structure of textiles in this dynamic region, and how it impacts both producers and consumers.

Raw Material Costs: The raw materials used in the production of textiles are the foundation upon which the entire supply chain rests. In Liaoning, the cost of raw materials such as cotton, wool, silk, and synthetic fibers varies based on the quality, quantity, and geographical origin of the raw materials. For instance, the cost of cotton, which forms the backbone of most domestic textile products, can vary significantly depending on whether it comes from the southern regions or the northern plains. Additionally, the rising global demand for certain types of raw materials has led to increased prices, further complicating the cost equation.

Labor Expenses: Manpower is another critical factor in the production costs of textiles. In Liaoning, labor is often provided by local workers, who are paid a wage based on their skill level and the complexity of the work involved. As the cost of living in the region rises due to factors like inflation, the cost of labor has also become a significant component of the overall production cost. Furthermore, with the increasing automation in manufacturing processes, the role of manual labor may decrease, but the cost of labor remains a crucial aspect of the overall production cost structure.

Transportation Logistics: The efficiency of transportation logistics plays a vital role in reducing the overall cost of producing textiles. In Liaoning, the region's proximity to major ports and railway hubs facilitates easy access to raw materials and finished goods, thereby reducing transportation costs. However, the high cost of fuel, particularly diesel, has contributed to the rising cost of transportation in recent years. Additionally, the need for specialized equipment and skilled drivers adds to the transportation costs, making the logistics process more expensive.

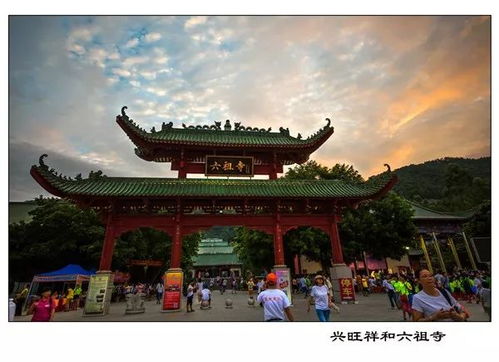

Market Dynamics: The market dynamics in Liaoning have a significant impact on the cost of domestic textiles. The region's unique blend of industries, including manufacturing, agriculture, and tourism, creates a diverse consumer base. The changing preferences and demands of this consumer base, coupled with the competition from international brands, influence the pricing strategies of domestic manufacturers. Additionally, the fluctuations in commodity prices, influenced by global market conditions, can have a profound effect on the cost of textiles produced in Liaoning.

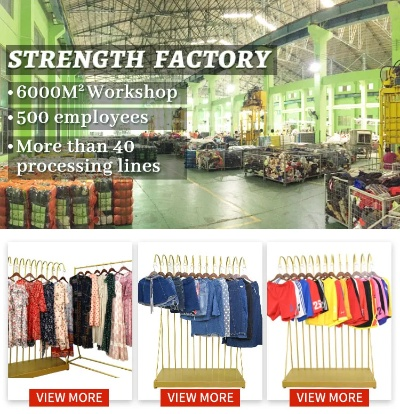

Case Study: To illustrate the complexities of the cost structure of textiles in Liaoning, let us consider the case of a local textile manufacturer named "Dalian Textile Co." Founded in 1990, this company specializes in producing high-quality garments using locally sourced cotton. Over the years, the company has faced several challenges in its quest to remain competitive in the highly competitive domestic market.

One of the primary challenges faced by Dalian Textile Co. was the rising cost of raw materials. To mitigate this issue, the company invested heavily in research and development to develop new fabric designs that could be produced at lower costs while maintaining quality. Another challenge was the rising cost of labor. To address this, Dalian Textile Co. implemented a flexible labor policy that allowed for better compensation and benefits for its employees. Additionally, the company invested in modernizing its production facilities to reduce energy consumption and improve efficiency.

Despite these efforts, Dalian Textile Co. still faced challenges in maintaining its position in the market. One reason for this was the changing preferences of consumers towards eco-friendly and sustainable clothing options. To address this trend, the company launched a line of organic cotton clothing that aligned with consumer expectations. Additionally, the company collaborated with local artists to create exclusive designs that appealed to a niche market.

Conclusion: In conclusion, the cost of domestic textiles in Liaoning is a complex web of interrelated factors that include raw material costs, labor expenses, transportation logistics, and market dynamics. While there are many ways to reduce these costs, such as investing in technology, improving efficiency, and adopting sustainable practices, it is essential to recognize that these measures will only be effective if they are implemented across all sectors of the industry. By understanding and addressing these challenges head-on, Liaoning's textile industry can continue to thrive while remaining competitive in today's global marketplace.

大家好,今天我们来谈谈辽宁省纺织品成本价的相关话题,随着全球贸易的不断发展,了解一个地区的纺织品成本价对于企业和消费者都具有重要意义,本篇文章将通过图表和案例分析,详细介绍辽宁省纺织品成本价的情况。

辽宁省纺织品成本概况

-

原材料成本:辽宁省主要依赖国内原材料进行纺织品生产,包括棉花、蚕丝、麻类等,这些原材料的价格波动较大,受到国内外市场供需关系、政策法规等多种因素的影响。

-

生产成本:包括人工成本、能源成本、设备折旧等,这些成本在不同地区和不同企业之间存在差异,受到地区经济发展水平、企业规模、技术水平等多种因素的影响。

案例分析

以某知名纺织品企业为例,该企业在辽宁省进行纺织品生产,其成本构成如下:

-

原材料成本:该企业主要采购国内棉花和蚕丝,价格相对稳定,企业还考虑了运输成本和关税等因素。

-

生产成本:该企业在设备折旧、员工薪酬、能源消耗等方面投入较大,人工成本是企业成本控制的关键因素之一,该企业通过优化人力资源配置、提高员工技能水平等方式,有效控制了人工成本,企业还采用了节能减排技术,降低了能源消耗和排放成本。

图表说明

以下是辽宁省纺织品成本的图表说明:

(请在此处插入图表)

从图表中可以看出,辽宁省纺织品成本受到多种因素的影响,包括原材料价格波动、生产成本结构等,不同地区和不同企业的成本也存在差异,某些地区由于政策法规等因素的影响,纺织品生产成本相对较低;而某些企业则通过技术创新、管理优化等方式提高了生产效率和控制成本的能力。

辽宁省纺织品成本价受到多种因素的影响,包括原材料价格波动、生产成本结构等,为了降低生产成本和提高竞争力,企业需要加强成本控制和优化管理,政府也需要加强政策引导和监管,促进纺织品产业的健康发展,消费者也需要了解纺织品成本价的相关信息,以便做出更明智的购买决策。

建议与展望

针对辽宁省纺织品产业的发展,我们提出以下建议:

-

加强政策引导和监管,促进纺织品产业的健康发展,政府可以出台相关政策措施,鼓励企业加强技术创新和产业升级,提高生产效率和产品质量水平。

-

优化供应链管理,降低生产成本和物流成本,企业可以加强与供应商的合作,优化供应链管理,提高原材料采购的效率和成本控制能力,企业还可以采用先进的物流技术和管理模式,提高物流效率和服务水平。

-

加强人才培养和引进,提高企业核心竞争力,企业可以加强人才培养和引进力度,提高员工技能水平和综合素质,增强企业的创新能力和竞争力,企业还可以通过技术创新和研发等方式,提高产品的附加值和市场竞争力。

辽宁省纺织品产业将继续发展壮大,成为当地经济发展的重要支柱产业之一,随着全球贸易的不断发展,纺织品产业也将面临更多的机遇和挑战,企业和政府需要加强合作和协调,共同推动纺织品产业的健康发展。

Articles related to the knowledge points of this article:

Dragonwell Medical Textile Factory:A Journey from Innovation to Quality