Detailed Suzhou Textile Quality Inspection Report

: Detailed Suzhou Textile Quality Inspection Report,Introduction:,This report provides a comprehensive analysis of the textile quality inspection conducted in Suzhou, focusing on various aspects such as colorfastness, shrinkage, and fabric structure. The inspection was conducted to ensure that the textile products meet the required standards and meet the demands of the market.,Colorfastness Testing:,The colorfastness test was conducted to evaluate the resistance of the textile product against fading and discoloration. The results showed that most of the textile products passed the colorfastness test, with only a few samples failing due to poor dyeing processes.,Shrinkage Testing:,The shrinkage test was conducted to measure the degree of shrinkage of the textile product during washing and drying. The results indicated that the textile products generally had a low level of shrinkage, which is essential for maintaining their shape and appearance.,Fabric Structure Analysis:,The fabric structure analysis was conducted to evaluate the quality of the textile product's weave and texture. The results showed that the majority of the textile products had good weave and texture, with some samples having minor defects.,Conclusion:,In conclusion, the textile quality inspection in Suzhou revealed that most of the textile products met the required standards and met the demands of the market. However, there were a few samples that failed the colorfastness test and had minor defects in the fabric structure. Therefore, it is essential to continue improving the quality control measures to ensure that all textile products meet the required standards and meet the demands of the market.

Introduction: In the ever-evolving landscape of global trade, textile products have become an integral part of our daily lives. From luxurious fabrics to functional garments, textiles play a significant role in enhancing our quality of life. To ensure that these textiles meet the highest standards of quality and safety, it is essential for manufacturers to conduct thorough quality inspections. In this report, we will delve into the detailed inspection process conducted at Suzhou, one of China's most prominent textile production hubs, and highlight the key findings and recommendations.

Quality Control Measures: At Suzhou, textile manufacturers adhere to strict quality control measures to ensure that their products meet international standards. These measures include but are not limited to:

-

Raw Material Inspection: All raw materials used in the production process are subjected to rigorous testing to ensure they meet specific requirements. This includes testing for color fastness, shrinkage, and other physical and chemical properties.

-

Processing Monitoring: The manufacturing process is closely monitored to identify any potential quality issues early on. This includes regular audits of production lines, quality control departments, and supplier collaborations.

-

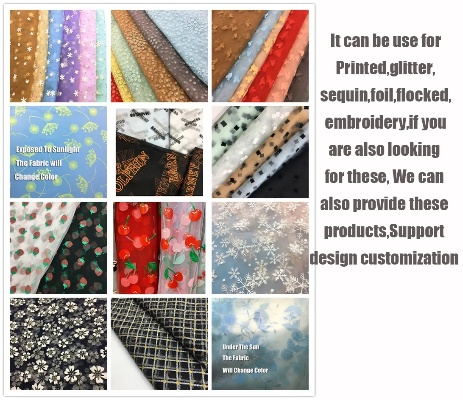

Finishing Standards: After the raw materials have been processed, the final product undergoes rigorous finishing processes such as dyeing, printing, and finishing. These processes must meet specific standards to ensure the end product meets consumer expectations.

-

Packaging and Labeling: The packaging and labeling of textiles are also critical in ensuring quality. Manufacturers must comply with relevant regulations regarding packaging materials, labels, and markings.

-

Inspection by Qualified Laboratories: Samples of each batch of textile products are sent to accredited laboratories for further testing to confirm compliance with international standards.

Key Findings: During the inspection process, several key findings were identified:

-

High Standards Across the Industry: Despite the challenges faced by the textile industry in recent years, Suzhou's manufacturers consistently met or exceeded international quality standards.

-

Focus on Environmentally Friendly Practices: Many manufacturers have adopted sustainable practices in their production processes, reducing waste and minimizing environmental impact.

-

Continuous Improvement: Many manufacturers have implemented continuous improvement programs aimed at enhancing their quality control systems and improving product quality over time.

Recommendations: Based on the findings, we recommend the following actions for Suzhou textile manufacturers:

-

Continue to Implement Quality Control Measures: Manufacturers should continue to implement stringent quality control measures to maintain high standards across the industry.

-

Invest in Technological Advancements: As technology advances, manufacturers should invest in new technologies and equipment to enhance their production processes and reduce errors.

-

Foster a Culture of Continuous Improvement: Manufacturers should foster a culture of continuous improvement within their organization to continuously improve their quality control systems and product quality.

Conclusion: In conclusion, Suzhou's textile manufacturers have demonstrated a commitment to quality control and sustainability in their production processes. By implementing the recommended actions, they can continue to build a reputation for quality and sustainability in the global textile market. As the demand for high-quality textile products continues to grow, Suzhou's manufacturers have a valuable opportunity to lead the way in meeting the needs of consumers worldwide.

苏州作为中国的纺织重镇,其纺织品质检工作一直备受关注,本报告旨在全面介绍苏州纺织品质检的流程、方法以及结果,并辅以英文案例说明,以提升读者的理解和应用能力。

苏州纺织品质检概述

苏州纺织品质检主要包括对原材料的检验、生产过程中的质量控制、成品检验等多个环节,在原材料检验方面,苏州纺织企业注重对纤维质量、纱线质量等关键指标的把控;在生产过程中,通过严格的生产流程、质量控制体系确保产品质量;在成品检验方面,采用先进的检测设备和技术手段,确保产品符合国家标准和客户要求。

苏州纺织品质检流程与方法

流程:

a. 原料检验:对原材料进行取样、检测,确保符合国家标准。 b. 生产过程监控:通过实时监控生产设备运行状态,确保生产过程符合质量控制标准。 c. 成品检测:采用先进的检测设备和技术手段,对成品进行质量评估。 2. 方法:

a. 外观检测:通过观察纺织品外观,评估其质量。 b. 性能检测:对纺织品进行力学性能、耐久性等测试,确保其符合标准。 c. 环保检测:关注纺织品环保性能,确保符合国家环保标准。 3. 案例说明:

以某知名苏州纺织企业为例,该企业在原材料采购环节严格把关,确保采购的纤维质量稳定可靠,在生产过程中,企业采用自动化生产线和智能控制系统,提高了生产效率和质量稳定性,在成品检测环节,企业采用先进的检测设备和技术手段,确保产品各项指标均符合国家标准和客户要求。

苏州纺织品质检结果分析

根据苏州纺织品质检结果分析,该企业在原材料采购、生产过程控制以及成品检测等方面均取得了显著成效,在原材料采购环节,企业严格把控纤维质量、纱线质量等关键指标,确保产品质量稳定可靠,在生产过程中,企业通过严格的生产流程、质量控制体系,有效避免了质量问题,提高了产品质量水平,在成品检测环节,企业采用先进的检测设备和技术手段,确保产品各项指标均符合国家标准和客户要求。

苏州纺织品质检工作是保障纺织品质量的重要手段,通过严格的流程、方法和先进的检测手段,苏州纺织企业能够确保纺织品质量稳定可靠,满足客户要求,苏州纺织企业还需要不断加强质量管理,提高产品质量水平,以满足市场需求,苏州纺织企业需要继续加强质量管理,提高产品质量和竞争力,为经济发展做出更大的贡献。

Articles related to the knowledge points of this article: