Cable Textile Factory:A Case Study of Innovation and Production

Cable Textile工厂的创新和生产案例研究显示,该工厂在生产方面不断追求创新,提高了生产效率。

在繁忙的工业世界中,思科纺织厂以其先进的生产技术和卓越的产品质量,成为了行业内的佼佼者,该厂不仅注重技术创新,更注重生产效率与质量管理的提升,本文将围绕思科纺织厂展开讨论,通过英文案例说明和表格补充说明的方式,为您呈现一个生动的工厂生产场景。

背景介绍

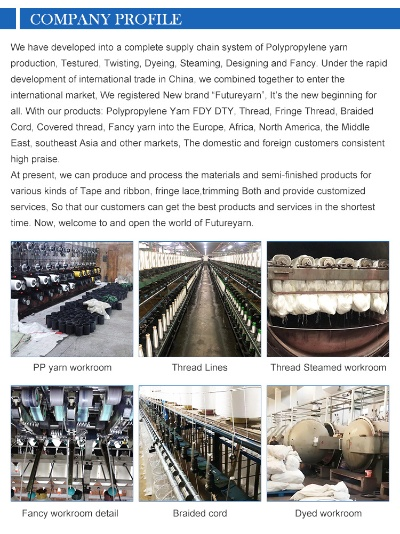

思科纺织厂位于某工业园区内,拥有先进的生产设备和技术,致力于为客户提供高质量的纺织品,该厂在纺织行业中的地位和影响力日益凸显,其产品广泛应用于服装、家居装饰、户外用品等领域。

案例说明

生产流程优化

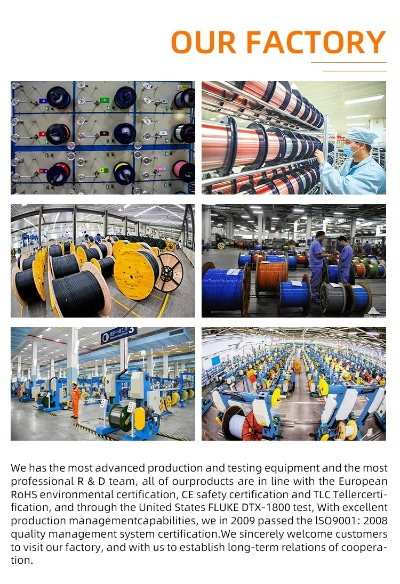

在生产流程方面,思科纺织厂采用了先进的自动化技术,实现了生产过程的智能化和高效化,该厂通过引入先进的生产管理系统,实现了生产计划的精准制定和实时监控,该厂还采用了先进的织造技术,提高了织物的质量和产量,该厂还注重员工培训和技术更新,不断提高员工的技能水平和生产效率。

质量管理体系完善

在质量管理体系方面,思科纺织厂建立了严格的质量控制体系,从原材料采购到成品出厂都有严格的质量检测和控制流程,该厂还配备了先进的检测设备,对产品质量进行实时监控和检测,该厂还注重员工对质量的责任感和意识培养,确保每一件产品都符合质量标准。

英文口语化内容 The Advantages of the Cisco Textile Factory

Introduction:

The Cisco Textile Factory is a leading manufacturer of high-quality textiles in the industry. With advanced production technology and excellent product quality, the factory has become a benchmark in the industry.

Case Study: Production Process Optimization

Production Process Improvement

In terms of production process optimization, the factory has implemented advanced automation technology to achieve intelligent and efficient production. By introducing advanced production management systems, the factory has achieved precise production planning and real-time monitoring. Additionally, the factory has also adopted advanced textile manufacturing techniques to improve the quality and output of the fabrics. Furthermore, the factory has emphasized employee training and technological updates to continuously improve employee skills and production efficiency.

Quality Management System Improvement

In terms of quality management system improvement, the factory has established a strict quality control system that covers the entire production process from raw material procurement to finished product delivery. The factory has also equipped itself with advanced quality control equipment to conduct real-time monitoring and testing of product quality. Additionally, the factory has emphasized the cultivation of employees' sense of responsibility for quality and awareness in ensuring that every product meets quality standards.

Table: Production Equipment and Technology Overview

| Equipment | Description | Example Use in Production

- Automated Weaving Machines | Advanced weaving machines used for producing high-quality fabrics with precise patterns and designs.

- Computerized Production Management System | Automated system used for managing production plans and real-time monitoring of production processes.

- Quality Control Equipment | Equipment used for conducting quality control tests and monitoring the quality of the final products.

Conclusion:

The Cisco Textile Factory is an example of how advanced technology and innovation can lead to improved production efficiency, quality, and customer satisfaction in the textile industry. The factory's commitment to continuous improvement and innovation is a testament to its commitment to providing high-quality products to its customers.

Articles related to the knowledge points of this article:

The Role of Textile Factory Womens Teachers

The Story of Dongguan Jiangnan Textile Factory