The 2021 Transformation:An In-depth Look at the Development of Textile Mills

In 2021, textile mills underwent a significant transformation. The industry faced numerous challenges due to the COVID-19 pandemic, but it also saw opportunities for innovation and growth. Textile mills have been rapidly adapting to new technologies such as automation, artificial intelligence, and digitalization. These changes have enabled them to improve efficiency, reduce costs, and enhance their competitiveness in the market.,One of the key areas of development was the integration of renewable energy sources. Many textile mills have started using solar panels and wind turbines to generate electricity, reducing their carbon footprint and lowering their energy costs. This has not only helped them to comply with environmental regulations but also increased their profitability.,Another trend is the focus on sustainability. Textile mills are now more concerned about the impact of their operations on the environment, and they are adopting practices such as reducing waste and using eco-friendly materials. This has led to the development of new products that are both stylish and sustainable.,Overall, the 2021 transformation has shown that textile mills can thrive in an era of rapid technological change. By embracing innovation and sustainability, they can continue to provide high-quality products to customers while minimizing their environmental impact.

Introduction: The textile industry has been a backbone of global economic growth for centuries. With the advent of advanced technology, the construction and operation of textile mills have undergone significant transformations in recent years. This year marks the 2021 edition, where we will delve into the latest advancements, challenges, and future prospects in the realm of textile mill construction.

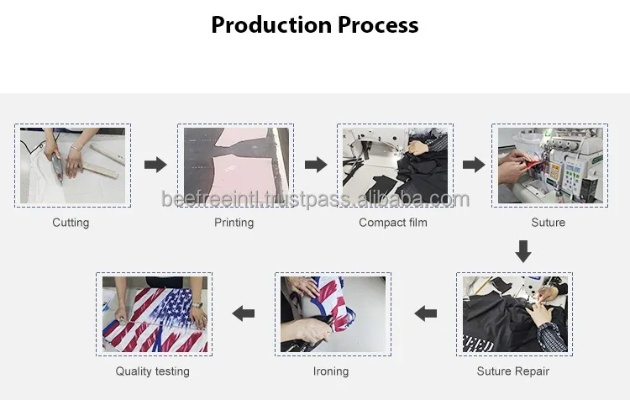

Advancements in Technology: The 2021 textile mills are equipped with state-of-the-art machinery and technology that enhances efficiency and productivity. For instance, robotic weaving machines have replaced manual labor, reducing downtime and increasing production capacity. Additionally, digital printing techniques have revolutionized the textile industry by allowing for intricate designs to be printed onto fabrics with ease.

Innovation in Design: The demand for sustainable and eco-friendly textiles is on the rise, leading to innovations in design. Fabrics made from recycled materials or biodegradable fibers are becoming increasingly popular, as consumers seek out products that align with their values. Furthermore, smart textiles that respond to changes in temperature or moisture levels are gaining traction, providing users with enhanced comfort and functionality.

Sustainability and Environmental Impact: As the world becomes more aware of environmental concerns, textile mills are adopting sustainable practices to minimize their impact on the environment. This includes using renewable energy sources like solar power to power machinery, implementing waste reduction strategies, and using eco-friendly materials in production.

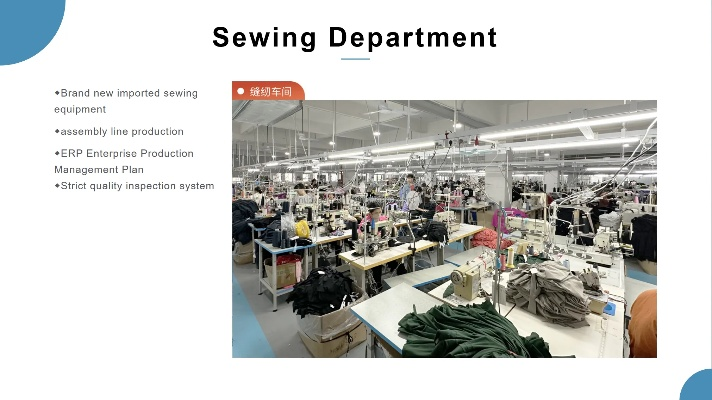

Case Study: One example of a successful textile mill construction project in 2021 is the expansion of a major textile company in China. The new mill employs state-of-the-art technology, including automated cutting and sewing machines, which significantly increased production efficiency. Additionally, the company incorporated green technologies such as rainwater harvesting systems and energy-efficient lighting fixtures, demonstrating a commitment to sustainability.

Challenges and Future Prospects: Despite the advancements in technology and design, there are still challenges facing textile mills. One major issue is the high cost of raw materials, particularly natural fibers such as cotton and wool. Additionally, the competition for resources and labor can be intense, making it challenging for smaller manufacturers to stay competitive.

Looking to the future, the textile industry is expected to continue its evolution towards automation, precision, and sustainability. As demand for eco-friendly and sustainable textiles continues to grow, it is likely that we will see even more innovative designs and technologies implemented in textile mills.

Conclusion: The construction of textile mills in 2021 represents a significant step forward in the industry's technological and design evolution. By embracing innovations in technology, sustainability, and design, textile mills can not only meet the demands of today's market but also prepare for tomorrow's challenges and opportunities. As we look to the future, it is clear that the textile industry will continue to evolve, driven by innovation and a desire to create products that not only meet but exceed consumer expectations.

随着国家经济的持续发展和人民生活水平的不断提高,纺织行业作为国民经济的重要支柱产业,其建设与发展显得尤为重要,在2021年,纺织厂的建设不仅关乎经济效益,更关乎环境保护和社会责任,本篇报告将详细介绍纺织厂建设的各个方面,包括规划、实施过程以及案例分析。

纺织厂建设规划

市场调研与分析

在纺织厂建设之前,首先进行市场调研与分析,通过收集国内外纺织行业的相关数据,了解市场需求、竞争态势和行业发展趋势,对当地资源、环境、政策等因素进行综合考虑,制定出符合当地实际情况的建设规划。

设计理念与布局规划

在设计纺织厂时,注重绿色环保、节能减排、高效生产等理念,根据市场需求和当地资源条件,设计出合理的布局规划,可以设置生产车间、辅助生产区、研发中心、仓库等区域,确保生产流程的顺畅进行,注重厂区绿化、节能设施的建设,提高厂区的环境质量。

设备选型与采购

在设备选型方面,根据生产工艺和设备需求,选择适合的设备和材料,注重设备的可靠性和稳定性,确保设备的正常运行和长期使用,在采购过程中,要严格把关,确保采购的设备符合国家相关标准和安全要求。

纺织厂建设实施过程

土地征用与拆迁

在纺织厂建设过程中,需要先征用土地并进行拆迁工作,拆迁工作要尽可能减少对当地居民的影响,确保拆迁工作的顺利进行,要做好拆迁补偿工作,保障被拆迁户的利益。

施工管理

在施工管理方面,要制定详细的施工计划,明确各项施工任务和时间节点,要建立完善的施工管理体系,确保施工过程的顺利进行和高效完成,在施工过程中,要注重安全文明施工,确保施工质量和人员安全。

设备安装与调试

在设备安装与调试方面,要严格按照设计要求进行安装和调试,要注重设备的维护和保养,确保设备的长期稳定运行,在调试过程中,要确保各项生产指标达到预期要求。

案例分析——某纺织厂建设成功案例

某纺织厂建设成功案例如下:

市场调研与分析

该纺织厂建设前进行了充分的市场调研与分析,通过对当地市场需求、竞争态势和行业发展趋势的了解,制定了符合当地实际情况的建设规划,该厂注重绿色环保、节能减排、高效生产等理念的应用,确保了生产流程的顺畅进行。

设计理念与布局规划

该纺织厂在设计时充分考虑了当地资源条件、环境因素以及生产需求,最终设计出合理的布局规划,包括生产车间、辅助生产区、研发中心等区域布局合理,有利于提高生产效率和产品质量,厂区绿化和节能设施的建设也得到了很好的体现。

设备选型与采购

该纺织厂在设备选型和采购方面也表现出了专业性,该厂选择了适合的生产设备和技术标准,确保了生产效率和产品质量的同时也符合国家相关标准和安全要求,注重设备的可靠性和稳定性,确保了设备的正常运行和长期使用。

纺织厂建设是一项复杂而重要的工程,需要从规划到实施各个环节都做到精心策划和严格管理,在未来的纺织厂建设中,应该注重绿色环保、节能减排、高效生产等理念的应用,同时也要注重设备选型和采购的合理性、科学性以及安全性,才能确保纺织厂建设的顺利进行和取得良好的经济效益和社会效益。

Articles related to the knowledge points of this article:

The Chemical Treatment in Textile Factory:药膏的使用与案例分析

The Story of Yiting Textile Factory

Textile Industrys Role in Creating Classical Skirt