The Latest Guidelines for the Use of Textile Dyes

The latest guidelines for the use of textile dyes have been published by the International Textile Federation (ITF), providing a comprehensive overview of the safe and effective application of these chemicals in the textile industry. The guidelines emphasize the importance of selecting appropriate dyes based on the type of fabric, colorfastness requirements, and environmental factors such as water quality and air pollution. They also recommend using dyes that are biodegradable or eco-friendly, reducing the risk of toxicity and environmental damage. Additionally, the ITF suggests implementing best practices for dyeing processes, such as proper mixing, temperature control, and monitoring to ensure uniform color coverage and minimal waste. Overall, the latest guidelines aim to promote sustainable and responsible textile dye usage, while ensuring high-quality finishes and customer satisfaction.

Introduction: In the world of textile manufacturing, dyes are essential for adding color and enhancing the overall appearance of fabrics. However, their use is subject to strict regulations to ensure safety, environmental sustainability, and product quality. This guide aims to provide you with the latest information on how to use dyes in a responsible and compliant manner. We will cover topics such as dye selection, application techniques, waste management, and more. By following these guidelines, you can create textile products that meet industry standards while minimizing potential harm to the environment. Let's dive into the details!

Dye Selection: Before selecting any dye for your textile project, it's crucial to consider factors such as colorfastness, lightfastness, wash fastness, and environmental impact. You should also research the dye's compatibility with other materials used in the production process. Here's an example of a table outlining some common dyes and their properties:

| Dye Type | Colorfastness | Lightfastness | Washfastness | Environmental Impact |

|---|---|---|---|---|

| Direct Dyes | High | Low | Moderate | Low |

| Indirect Dyes | Medium | Low | High | Moderate |

| Reactive Dyes | Very high | High | High | High |

Case Study: Consider the case of a manufacturer who was using a direct dye in their cotton shirts. They found that the shirts had discoloration after washing, despite being labeled as "colorfast." Upon investigation, they discovered that the dye had not been properly applied or had been exposed to certain chemicals during processing. As a result, they switched to an indirect dye and experienced significant improvement in color stability and overall product quality.

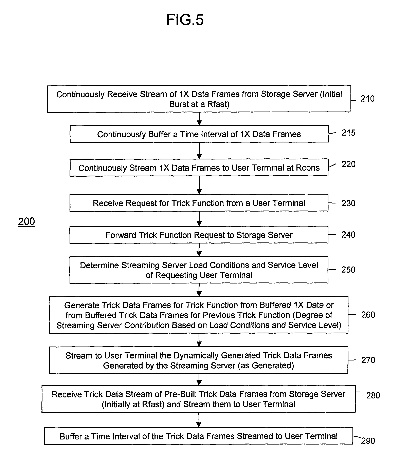

Application Techniques: When applying dyes to textiles, it's important to follow proper procedures to ensure even distribution and avoid uneven shades. Here are some key points to keep in mind:

- Pre-treatment: Before applying the dye, ensure that the fabric is properly washed and dried. This helps prevent clumping and ensures even coverage.

- Dye concentration: Use the correct amount of dye based on the fabric weight and desired shade. Overloading can lead to blotches and streaks.

- Application method: There are several methods for applying dye, including pad-dry-cure, pad-wet-cure, and spray-dry-cure. Choose the method that best suits your specific needs and fabric type.

- Drying time: Follow the manufacturer's instructions for drying times. Prolonged exposure to heat or moisture can cause discoloration or shrinkage.

- Testing: Before mass production, test small batches of fabric to ensure uniformity and quality.

Waste Management: Proper waste management is essential to minimize environmental impact when using dyes. Here are some tips for managing dye waste:

- Segregate: Ensure that dye waste is separated from other waste streams to prevent contamination.

- Recycling: Consider recycling dye effluents rather than dumping them into landfills or waterways.

- Composting: If possible, compost dye waste instead of sending it to a landfill.

- Donating: Consider donating excess dye to organizations that recycle or repurpose textile scraps.

Conclusion: In conclusion, the use of dyes in textile manufacturing requires careful consideration of various factors, including dye selection, application techniques, waste management, and environmental impact. By following the latest guidelines outlined in this guide, you can create textile products that meet industry standards while minimizing harm to the environment. Remember, responsible use of dyes is essential for ensuring long-term success in the textile industry.

随着纺织行业的快速发展,染料作为纺织品加工过程中的关键材料,其使用规范也日益受到重视,本篇旨在介绍纺织品染料使用规范的最新要求和实际操作,并结合实际案例进行说明。

染料使用规范概述

染料类型与选择

染料种类繁多,根据纺织品的不同材质、用途和颜色需求,选择合适的染料至关重要,应遵循环保、安全、高效的原则,选择符合国家标准和行业要求的染料。

使用环境与条件

在使用染料时,应确保染料存储环境干燥、通风、无污染,同时根据纺织品类型和染色工艺要求调整染料浓度和温度等条件。

使用方法与注意事项

在使用染料时,应遵循正确的操作方法,注意安全防护和环境保护,应避免混用不同品牌、类型的染料,以免影响染色效果和纺织品质量。

最新染料使用规范要求

环保要求

染料生产企业应遵守环保法规,采用环保染料,减少对环境的污染,纺织品生产企业也应加强环保意识,推广绿色生产。

安全要求

在使用染料时,应确保操作安全,避免对人体和环境造成危害,应遵守相关安全操作规程,佩戴防护用品,确保操作人员安全。

高效要求

染料应具有高效染色性能,能够满足纺织品染色工艺的要求,应关注染料的环保性能和染色效果,确保染色过程环保、高效。

实际案例说明

某纺织品公司染料使用规范案例

某纺织品公司采用环保染料进行纺织品染色,严格按照染料使用规范操作,选择符合环保要求的染料;确保存储环境干燥、通风;根据纺织品类型和染色工艺要求调整染料浓度和温度等条件,该公司的染色过程高效、环保,得到了客户的高度认可。

染料混用问题案例

有些纺织品生产企业为了降低成本或追求更高的染色效果,混用不同品牌、类型的染料,这种做法不仅会影响染色效果和纺织品质量,还可能引发安全问题,纺织品生产企业应严格遵守染料使用规范,避免混用不同品牌、类型的染料。

总结与建议

纺织品染料使用规范的最新要求和实际操作需要遵循环保、安全、高效的原则,生产企业应加强环保意识,推广绿色生产;应严格按照染料使用规范操作,确保染色过程环保、高效,还应关注染料的环保性能和染色效果,确保产品质量和客户满意度。

建议

为了更好地推广纺织品染料使用规范的最新要求和实际操作,建议加强宣传教育,提高生产企业和社会公众的环保意识;加强行业自律,推动染料行业健康发展;还应加强技术研发和创新,提高染料的环保性能和染色效果。

Articles related to the knowledge points of this article:

Shanghai Yudi Textiles:A Legacy of Innovation and Excellence