The Dynamics of Yilong Textile Factory

The Yilong Textile Factory is a leading textile enterprise located in the Yangtze River Delta region of China. This factory employs over 500 people and produces various types of fabric, including cotton, polyester, and blended yarns. The factory has been operating since 1980 and has expanded its production capacity over the years to meet the growing demand for textile products in the market. The factory uses advanced technology and equipment to manufacture high-quality textiles that are sold to retailers and exporters around the world.,In recent years, the Yilong Textile Factory has focused on innovation and development, introducing new designs and colors into its product range to meet the changing needs of customers. Additionally, the factory has established partnerships with other textile companies in the region and beyond to enhance its competitiveness in the industry. Overall, the Yilong Textile Factory plays an essential role in the textile industry and continues to contribute to the growth and prosperity of the region.

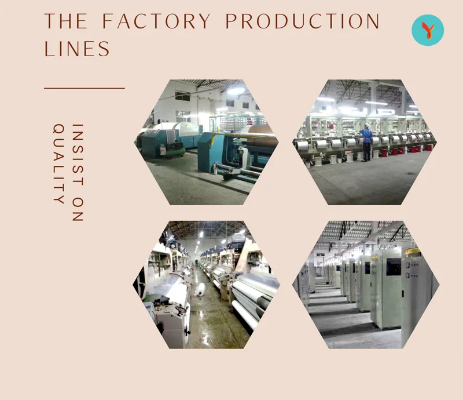

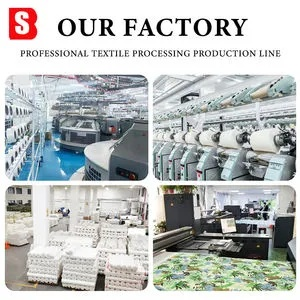

Welcome to the world of textile manufacturing, where every thread is crafted with precision and passion. Yilong Textile Factory stands out from the rest as it is not just a factory but a beacon of innovation, sustainability, and quality in the industry. Let's dive into the fascinating journey of one of China's most renowned textile enterprises.

Yilong Textile Factory: A Tale of Craftsmanship and Innovation

At Yilong Textile Factory, each fabric is a testament to the dedication of our team of skilled artisans. With over 50 years of experience, we have honed our craft through generations of expertise, resulting in products that are both functional and visually stunning.

Our production process is meticulously managed, starting with high-quality raw materials sourced from trusted suppliers. These materials are then processed through an intricate series of steps, ensuring that each fabric is soft and durable. Our cutting-edge machinery ensures maximum output efficiency while maintaining the highest level of consistency across all products.

But what truly sets Yilong apart is our commitment to sustainability. We have implemented eco-friendly practices throughout our supply chain, from using renewable energy to minimizing waste. Our goal is to produce textiles that not only look great but also contribute to a healthier planet.

To further illustrate the innovative spirit at Yilong, let us take a closer look at one of our recent projects. Our team collaborated with a leading fashion designer to create a collection of sustainable and stylish clothing for women. This project required advanced technology and creative design, but it was a success, showcasing the power of collaboration between craftsmanship and innovation.

Tableau: Yilong Textile Factory Production Process

| Phase | Process | Output |

|---|---|---|

| 1 | Pre-production | Raw material sourcing and processing, product design, and pattern preparation |

| 2 | Production | Cutting and weaving, finishing and sewing processes |

| 3 | Quality Control | Checks for color consistency, texture, and stitching precision |

| 4 | Packaging | Ensuring proper packaging for shipment and storage |

As you can see, every step is designed to ensure that the final product meets or exceeds industry standards. Our commitment to quality extends beyond just the finished product; we believe in continuous improvement and customer satisfaction.

In conclusion, Yilong Textile Factory is more than just a manufacturer; it is a symbol of excellence in textile craftsmanship and sustainability. With a focus on innovation, craftsmanship, and environmental responsibility, we strive to make a lasting impact in the global textile industry. So why not visit our factory and experience the wonders for yourself?

艺龙纺织厂作为一家专注于纺织行业的现代化企业,以其先进的生产技术、环保理念和可持续发展战略,在行业内树立了良好的口碑,本文将围绕艺龙纺织厂展开,介绍其生产流程、环保措施、技术创新以及未来展望。

生产流程

- 原料采购:艺龙纺织厂从优质的原材料供应商处采购高质量的棉花、涤纶等原料,确保产品质量。

- 生产线设置:艺龙纺织厂拥有先进的生产线,采用环保、节能的生产设备,确保生产过程的环保和效率。

- 织造工艺:采用先进的织造技术,如数字化织造、智能控制等,提高织物的质量和效率。

- 印染工艺:采用环保染料和工艺,减少对环境的污染。

- 成品检验:对成品进行严格的质量检测,确保产品质量符合国家标准。

环保措施

- 节能减排:艺龙纺织厂注重节能减排,采用先进的节能设备和技术,减少能源消耗和排放。

- 废物处理:艺龙纺织厂设有专门的废物处理设施,对生产过程中产生的废物进行分类、回收和处理,确保环境安全。

- 绿色包装:采用环保包装材料,减少包装废弃物对环境的影响。

- 绿色供应链:与优质的原材料供应商建立长期合作关系,确保原材料的可持续性和环保性。

技术创新

- 数字化织造技术:艺龙纺织厂采用数字化织造技术,提高织物的质量和效率,降低生产成本。

- 智能控制技术:采用智能控制技术,实现生产过程的自动化和智能化,提高生产效率和产品质量。

- 绿色染料研发:研发环保、高效的绿色染料,减少对环境的污染。

- 绿色能源利用:利用太阳能、风能等可再生能源,降低能耗和排放。

案例说明

以艺龙纺织厂为例,介绍其在环保和可持续发展方面的具体实践。

- 原料采购与质量控制:艺龙纺织厂从优质的原材料供应商处采购高质量的棉花、涤纶等原料,建立严格的质量控制体系,确保产品质量符合国家标准,艺龙纺织厂注重环保和可持续性,采用环保包装材料和绿色能源利用等措施,降低对环境的影响。

- 生产过程与技术创新:艺龙纺织厂采用先进的生产线和环保、节能的生产设备,提高生产效率和产品质量,艺龙纺织厂注重技术创新,研发环保、高效的绿色染料和绿色能源利用等新技术,降低能耗和排放,艺龙纺织厂还积极推广绿色工艺和可持续发展战略,提高企业的社会责任感和品牌形象。

- 环境监测与治理:艺龙纺织厂设有专门的环保监测机构和环境治理设施,对生产过程中的环境因素进行监测和控制,艺龙纺织厂还积极参与环保事业和社会公益活动,为社会做出贡献。

展望未来,艺龙纺织厂将继续加强环保和可持续发展战略的实施,提高企业的社会责任感和品牌形象,艺龙纺织厂将继续注重技术创新和环保理念的应用,推动企业向更高质量、更高效率、更可持续的方向发展,艺龙纺织厂还将积极推广绿色工艺和可持续发展战略,为行业的可持续发展做出更大的贡献。

Articles related to the knowledge points of this article:

Textile Factory Apprentice Learning Experience

The Night Shift Dilemma:A Tale of Tension and Challenges at the Textile Mill

The Story of Danyang Huayang Textile Factory

The Lisa Textile Factory:An Industrys Journey from the Past to Today