The Fabric of Success:An Insight into the Dynamics of Hangxin Textile Factory

Introduction: In the tapestry of global textile industry, Hangxin Textile Factory stands out as a beacon of innovation and excellence. With its commitment to sustainability, quality, and customer satisfaction, this factory has carved out a niche for itself in the competitive arena. In this article, we will delve into the fascinating world of Hangxin Textile Factory, exploring its history, processes, and achievements. Let's embark on a journey through the fabric of success that Hangxin Textile Factory has woven over time.

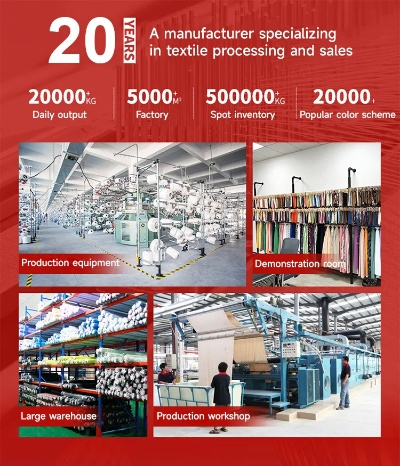

Historical Background: Hangxin Textile Factory was established in 1985, initially focusing on producing basic garments. Over the years, the factory expanded its product range to include a variety of textile products, including home furnishings, sportswear, and even fashion accessories. The journey began with humble beginnings, but it was the relentless pursuit of quality that transformed Hangxin into a leading player in the textile industry.

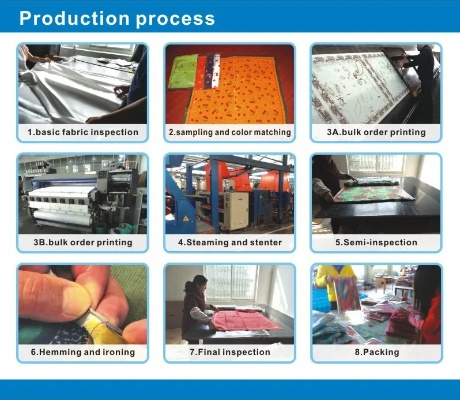

Processes: At Hangxin Textile Factory, every thread is treated with the same level of care and precision as the final product. Here are some key processes that define the factory's manufacturing process:

-

Design and Planning: The design team at Hangxin Textile Factory works tirelessly to develop innovative designs that meet the demands of today's consumers. They collaborate closely with designers from around the world to bring new ideas to life. Once the design is approved, the planning team maps out the production process, ensuring that each step aligns with the overall vision.

-

Raw Material Collection: Hangxin Textile Factory sources its raw materials from trusted suppliers who prioritize sustainability and ethical practices. The selection process involves rigorous inspections to ensure that only high-quality fibers are used. These raw materials are then processed to create the foundation for the textile products.

-

Pre-treatment: Before weaving, the raw materials undergo a series of pre-treatment steps to enhance their strength and durability. This includes treatments such as dyeing, printing, and finishing, which transform the fibers into vibrant colors and smooth textures.

-

Weaving: The heart of the manufacturing process lies in the weaving stage. Here, skilled artisans work with precision to create intricate patterns and designs. The machines used for weaving are highly automated, ensuring consistent quality and efficiency.

-

Finishing: Once the weaving process is complete, the textile products undergo a series of finishing steps to enhance their appearance and functionality. This includes treatments such as dyeing, printing, and finishing, which help to protect the fabric and make it more durable.

-

Packaging: Finally, the finished textile products are packaged carefully to ensure they reach their destination in perfect condition. This involves using eco-friendly materials and ensuring that the packaging is designed to minimize waste and reduce environmental impact.

Achievements: Over the years, Hangxin Textile Factory has achieved numerous milestones that have contributed to its success. Some of these achievements include:

-

Innovation Award: In 2015, Hangxin Textile Factory won an Innovation Award for its sustainable approach to textile production. This recognition highlights the company's commitment to creating eco-friendly products that are both stylish and functional.

-

Green Product Standard: In 2017, Hangxin Textile Factory became the first company in China to achieve the Green Product Standard for textiles. This certification signifies the company's dedication to reducing its environmental footprint and promoting sustainable practices.

-

Customer Satisfaction: Hangxin Textile Factory has consistently received high ratings from customers for its exceptional quality and customer service. The company's commitment to delivering exceptional products has helped it build a loyal customer base that continues to grow.

Conclusion: As we conclude our exploration of Hangxin Textile Factory, it's clear that this factory is not just another textile manufacturer; it's a true pioneer in the field of sustainable textile production. From its innovative designs to its commitment to ethical sourcing and eco-friendly practices, Hangxin Textile Factory has set a new standard for the industry. As we move forward, it's important for other textile manufacturers to emulate the success of Hangxin Textile Factory and strive to create textile products that not only look great but also contribute to a better tomorrow.

航信纺织厂概述

航信纺织厂是一家专注于纺织行业的现代化工厂,致力于生产高品质、环保、可持续的纺织品,该厂采用先进的生产技术,注重绿色制造和可持续发展,为消费者提供健康、环保的纺织品。

航信纺织厂的生产流程

- 原料采购:航信纺织厂从优质的原材料供应商处采购高质量的棉花、丝绸等原料,确保产品质量。

- 纺织加工:在纺织加工过程中,采用环保设备和技术,减少环境污染和资源浪费,注重生产效率,提高生产效益。

- 质量控制:航信纺织厂建立严格的质量控制体系,确保产品符合国家标准和客户需求。

- 包装与物流:产品包装采用环保材料,确保产品运输过程中减少环境污染,采用先进的物流系统,提高物流效率。

航信纺织厂的绿色制造实践

- 节能减排:航信纺织厂积极推广节能减排技术,降低能源消耗和排放,采用高效节能设备、优化生产流程等。

- 循环利用:航信纺织厂注重废旧材料的回收和再利用,减少废弃物产生,积极推广循环经济理念,提高资源利用效率。

- 绿色环保材料使用:航信纺织厂使用环保材料生产纺织品,减少对环境的污染,使用可降解材料、天然纤维等环保材料。

- 绿色供应链管理:航信纺织厂与供应商建立长期合作关系,确保原材料的质量和供应稳定性,积极推广绿色采购和回收利用政策,降低供应链成本。

案例说明

以航信纺织厂为例,介绍其在绿色制造方面的成功实践和经验教训。

-

成功实践: (1)原料采购:航信纺织厂从优质的原材料供应商处采购高质量的棉花和丝绸原料,确保产品质量的同时,降低生产成本。 (2)生产技术:采用先进的纺织加工技术和环保设备,提高生产效率和质量,注重生产过程中的节能减排和循环利用。 (3)质量控制:建立严格的质量控制体系,确保产品符合国家标准和客户需求,积极推广质量管理体系认证和客户满意度调查。 (4)绿色环保材料使用:使用环保材料生产纺织品,减少对环境的污染,使用可降解材料替代有毒有害材料,推广天然纤维等环保材料的使用。

-

经验教训: (1)加强技术研发和创新:继续加强技术研发和创新,提高生产效率和产品质量的同时,降低生产成本和环境污染。 (2)加强人才培养和引进:加强人才培养和引进力度,提高员工素质和生产技能水平,积极推广绿色制造理念和可持续发展理念。 (3)加强宣传和教育:加强宣传和教育力度,提高社会对绿色制造和可持续发展的认识和重视度。

航信纺织厂在绿色制造方面取得了显著成果和经验教训,通过推广节能减排、循环利用、绿色环保材料使用等措施,提高了生产效率和产品质量的同时,降低了环境污染和资源浪费,加强技术研发和创新、人才培养和引进以及宣传和教育等方面的工作,为绿色制造和可持续发展做出了积极贡献,航信纺织厂将继续加强绿色制造和可持续发展工作,为消费者提供更加健康、环保的纺织品。

Articles related to the knowledge points of this article:

A Brief Guide to the Fabrication Process at Shang Li Textile Factory

The Transformation of Yangquan Mu County Textile Factory

The Disaster at Qidong Textile Factory

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation