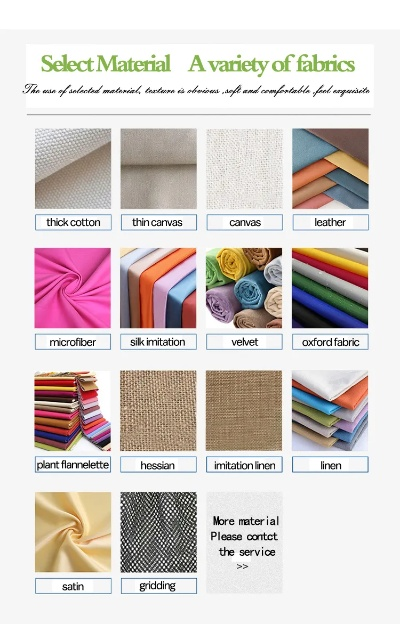

The Transformative Power of Plastic in Textiles

In recent years, the use of plastic in textiles has become increasingly prevalent. This is due to the fact that plastic materials are lightweight, durable and flexible, making them ideal for use in clothing and other textile products. The transformational power of plastic in textiles lies in its ability to enhance the aesthetic appeal and functionality of these products. For example, plastic can be used to create intricate patterns and designs on textiles, giving them a unique and eye-catching look. Additionally, plastic can be used to add texture and dimension to fabrics, creating a more interesting and dynamic appearance. Furthermore, plastic can also be used to improve the durability and longevity of textiles, extending their lifespan and reducing the need for frequent replacement. Overall, the utilization of plastic in textiles has the potential to revolutionize the fashion industry, offering new possibilities for creativity and innovation.

Introduction: The textile industry is a vital part of our daily lives, providing comfort, style, and functionality. However, with the increasing demand for sustainable and eco-friendly materials, the use of plastic in textile production has become a topic of discussion. In this essay, we will explore the various ways plastic can be used as a raw material in textile manufacturing, including its applications, advantages, challenges, and potential future developments.

Plastic in Textiles: A Comprehensive Guide

-

Polyester and Nylon Polyester and nylon are two of the most popular synthetic fibers used in textiles. They are derived from petrochemicals and have excellent strength, durability, and resistance to water and chemicals. For example, polyester fabrics are commonly used in sportswear, while nylon is preferred for outdoor clothing due to its lightweight and breathability properties.

-

Polypropylene (PP) PP is a thermoplastic polymer that is widely used in the production of plastic bags, bottles, and other packaging materials. It is also an important component in the manufacture of textiles such as denim jeans and carpets. PP is known for its high tensile strength and resistance to UV radiation, making it suitable for outdoor and industrial applications.

-

Polyethylene (PE) PE is a semi-crystalline polymer that is commonly used in the production of films, containers, and packaging materials. It is also an essential ingredient in the production of polyester and nylon fibers. PE is known for its flexibility, transparency, and low cost, making it a popular choice for consumer goods like clothing and home textiles.

-

Polyvinyl Chloride (PVC) PVC is a versatile plastic material that is used in the production of pipes, flooring, and building materials. It is also a key component in the manufacture of textiles such as curtains and upholstery. PVC is known for its toughness and durability, making it ideal for outdoor and industrial applications.

-

Polyurethane (PU) PU is a type of elastomer that is used in the production of foams, adhesives, and protective coatings. It is also an important raw material for the manufacture of textiles such as gloves, hats, and swimwear. PU is known for its softness and flexibility, making it suitable for intimate apparel and fashion accessories.

Advantages of Plastic in Textiles:

-

Cost-Effectiveness: Plastic-based textiles are often cheaper than their natural counterparts, making them more accessible to consumers. This is particularly true for low-end markets where price is a critical factor.

-

Durability: Plastic-based textiles are highly durable, resistant to wear and tear, and can last longer than traditional textiles. This makes them ideal for outdoor activities, sportswear, and workwear.

-

Versatility: Plastic-based textiles can be designed and shaped into a wide range of products, from clothing to furniture. This allows manufacturers to create unique designs and patterns that would be difficult or impossible to achieve with natural fibers.

-

Environmental Benefits: Plastic-based textiles have a lower environmental impact compared to traditional textiles made from natural fibers. They require less water and energy to produce, and they can be recycled or reused multiple times.

Challenges of Plastic in Textiles:

-

Pollution: The production of plastic-based textiles involves the use of petrochemicals, which can contribute to air and water pollution. This is particularly problematic in developing countries where there is limited access to clean water and energy resources.

-

Health Concerns: Some plastic-based textiles may contain harmful chemicals or additives that can leach into the body during use or washing. This can lead to health problems such as allergies or skin irritation.

-

Landfill Emissions: When plastic-based textiles are discarded at landfill sites, they can release greenhouse gases into the atmosphere, contributing to climate change. This is a significant concern given the growing awareness of climate change issues.

Potential Future Developments:

As technology advances and new materials become available, there is potential for further innovation in the field of textiles using plastic. For example, researchers are exploring the use of biodegradable plastics that can break down naturally without causing harm to the environment. Additionally, there is interest in developing new types of plastic that are more sustainable and eco-friendly, such as those derived from renewable sources or made from recycled plastic waste.

Conclusion: In conclusion, plastic is a versatile and cost-effective material that can be used in the production of textiles. While there are challenges associated with its use, such as pollution, health concerns, and landfill emissions, the potential benefits of plastic-based textiles make them a promising area for future development. As research continues, we can expect to see continued innovation and advancements in the field of textile manufacturing using plastic.

塑料纺织品概述

塑料是一种广泛应用的材料,具有多种优点,如轻便、耐用、可塑性强等,它们在纺织领域的应用非常广泛,可以制成各种类型的纺织品,以下是一些塑料纺织品的主要种类及其应用案例:

塑料纺织品种类

| 材料类型 | 常见应用 | 示例产品 |

|---|---|---|

| 聚乙烯(PE) | 服装面料 | 运动服、休闲装 |

| 聚丙烯(PP) | 家居装饰品 | 窗帘、地毯、壁挂式装饰物 |

| 聚氯乙烯(PVC) | 功能性纺织品 | 防水布、防滑垫、过滤材料 |

| 塑料薄膜 | 纺织面料 | 布料、包装材料等 |

| 其他塑料复合材料 | 其他功能性纺织品 | 如抗菌、防紫外线等特殊处理面料 |

案例说明

- 聚乙烯(PE)服装面料

在服装行业中,聚乙烯因其轻便、耐用和可塑性强等特点,被广泛应用于制作各种类型的服装面料,运动服通常使用聚乙烯材料,因其良好的透气性和耐用性,使得运动员在运动时能够保持舒适和活力,休闲装也经常使用聚乙烯材料,因其时尚感和舒适感吸引消费者。

- 塑料薄膜纺织面料

塑料薄膜是一种薄型材料,广泛应用于纺织品的生产中,布料通常使用塑料薄膜作为基材,制作各种类型的服装、家居装饰品等,塑料薄膜还可以用于制作包装材料、过滤材料等,在某些情况下,塑料薄膜还可以通过特殊处理技术,如抗菌处理或防紫外线处理,来提高其功能性。

塑料与纺织的结合方式

为了更好地展示塑料纺织品的应用和特性,我们可以使用表格进行说明:

| 材料类型 | 应用领域 | 与纺织的结合方式示例 |

|---|---|---|

| 聚乙烯(PE) | 服装面料 | 采用先进的纺织工艺,如织造、印花等 |

| 塑料薄膜 | 纺织面料 | 使用特殊的涂层或复合技术,提高其功能性 |

| 其他塑料复合材料 | 其他功能性纺织品 | 通过添加特殊纤维或添加物,提高其性能和耐用性 |

英文案例说明

塑料纺织品在时尚界的运用

在时尚界中,塑料纺织品的应用越来越广泛,某些设计师开始使用聚乙烯材料制作时尚的服装面料,以其轻便、耐用的特性吸引消费者,一些品牌也开始使用特殊的涂层或复合技术,将塑料纺织品与其他材料结合在一起,制作出具有独特风格和功能的时尚产品,这些产品不仅具有时尚感,而且具有很高的实用性和耐用性。

塑料薄膜在环保领域的运用

塑料薄膜在环保领域的应用也非常广泛,某些公司开始使用回收的塑料薄膜作为生产包装材料的原料,以减少对环境的影响,一些公司还通过添加抗菌或防紫外线处理技术,提高塑料薄膜的环保性能和功能性,这些产品不仅具有环保性,而且具有很高的实用性和美观性。

塑料纺织品是一种具有广泛应用前景的材料,可以制成各种类型的纺织品,通过不断的研究和创新,我们可以进一步发掘其更多的应用领域和功能特性。

Articles related to the knowledge points of this article:

The Story of Gold Dust Textiles at Dassong

Comprehensive Analysis of Linchang Textile Logistics Route Prices

The Journey of Exquisite Durable Textiles an Insight into 秀力达纺织品

The Enigmatic World of Industrial Fabrics and Their Variegated Spectrum