Textiles:Navigating the Challenges of Heat-Resistant and Lightfasting Yellowing

The textile industry has faced significant challenges in recent years, particularly in terms of heat resistance and lightfastness. This article discusses the various methods used to address these issues, including using more durable dyes and fabric treatments, as well as incorporating anti-yelloing agents into the manufacturing process. Additionally, it explores the importance of proper care and storage for maintaining the longevity of these materials. By understanding the complexities of this topic, manufacturers can better meet consumer demands and ensure that their products remain attractive and functional for years to come.

In the world of textiles, color stability is a critical factor that determines the longevity of products. Yellowing, or fading, is one of the most common causes of color loss in fabrics. This article will explore the topic of textiles' resistance to heat-induced yellowing and how it can be improved through various methods. We will also provide an example of how this technology has been applied successfully in the industry.

Understanding Yellowing in Textiles

Yellowing occurs when the pigments in a textile material fade over time due to exposure to light, heat, or moisture. The process is accelerated by certain chemicals present in the fabric, such as dyes and finishers. Heat-induced yellowing is particularly problematic because it often leads to discoloration that is difficult to remove once it has occurred.

Heat-Resistant Technology

To combat heat-induced yellowing, manufacturers have developed various technologies. One approach is the use of antioxidants, which are compounds that prevent oxidative reactions that cause yellowing. These antioxidants can be incorporated into the fabric during the dyeing process or added later as finishing agents.

Another method is to use ultraviolet (UV) inhibitors, which are substances that absorb UV light and prevent it from reaching the pigments in the fabric. UV inhibitors can be used in combination with antioxidants to further enhance the fabric's resistance to yellowing.

Case Study: Successful Application of Heat-Resistant Technology

One example of how heat-resistant technology has been applied successfully is in the production of high-performance sportswear. In this case, the fabric is designed to withstand intense heat and humidity, which can cause rapid yellowing. To achieve this, manufacturers use advanced dyeing techniques that incorporate heat-resistant antioxidants and UV inhibitors.

The result is a fabric that maintains its vibrant colors even after extensive wear and washing. This technology not only enhances the product's performance but also extends its lifespan significantly, making it more cost-effective for consumers.

Conclusion

Textiles' resistance to heat-induced yellowing is crucial for maintaining their quality and appearance over time. By incorporating heat-resistant technology into the fabric manufacturing process, manufacturers can create products that are both durable and visually appealing. With advancements in technology, we can expect to see further improvements in this area, leading to even more innovative solutions for protecting our clothing and other textiles from yellowing.

随着现代工业的快速发展,纺织品在高温环境下使用越来越普遍,耐高温黄变是纺织品性能的一个重要指标,它关系到产品的使用寿命和外观质量,本文将围绕纺织品耐高温黄变这一主题展开讨论,并通过英文案例说明来进一步阐述。

纺织品耐高温黄变的重要性

纺织品耐高温黄变是指纺织品在高温环境下出现颜色变化的现象,这种变化通常是由于纺织品中的染料在高温下发生化学反应所致,纺织品耐高温黄变不仅影响产品的外观,还关系到产品的使用寿命和性能。

纺织品耐高温黄变的原因分析

- 染料类型与性能:不同类型的染料在高温下的性能不同,有些染料在高温下容易发生化学反应,导致颜色变化。

- 环境因素:纺织品在使用过程中,受到环境因素的影响,如温度、湿度、光照等,这些因素都会影响染料的颜色稳定性。

- 纺织工艺:纺织工艺对纺织品耐高温黄变也有一定的影响,某些特殊的纺织工艺可以改善染料的颜色稳定性。

纺织品耐高温黄变的案例分析

某品牌的高温纺织品

该品牌的高温纺织品采用了特殊的染料和纺织工艺,可以有效抵抗高温黄变,该品牌的高温纺织品在长时间的高温环境下使用,颜色始终保持鲜艳,没有出现明显的颜色变化。

其他纺织品存在的问题

在某些情况下,纺织品在使用过程中可能会出现颜色变化的问题,某些纺织品在使用过程中受到环境因素的影响,颜色逐渐变暗或出现其他颜色变化,这可能是由于染料在高温下的稳定性不够,或者纺织工艺不够完善等原因所致。

纺织品耐高温黄变的测试方法与标准

为了评估纺织品耐高温黄变性能,通常需要进行以下测试方法与标准:

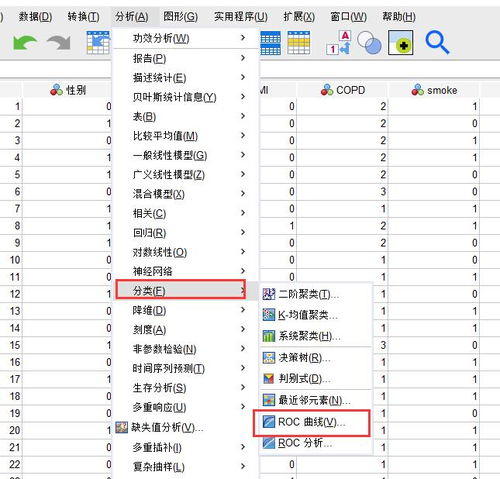

- 测试方法:可以采用实验室测试方法,如热重分析(TGA)、差热分析(DTA)等,来评估染料在高温下的稳定性,还可以通过观察纺织品在使用过程中的颜色变化情况来评估其耐高温黄变性能。

- 测试标准:根据不同的纺织品类型和用途,可以参考相关的国家标准或行业标准来评估纺织品耐高温黄变性能,可以根据纺织品的使用环境、使用时间等因素来制定相应的测试标准。

提高纺织品耐高温黄变性能的措施

为了提高纺织品耐高温黄变性能,可以采取以下措施:

- 选择稳定性好的染料:选择稳定性好的染料是提高纺织品耐高温黄变性能的重要措施之一。

- 优化纺织工艺:优化纺织工艺可以改善染料的颜色稳定性,提高纺织品的耐高温黄变性能,可以采取特殊的纺织工艺来提高染料的分散性、牢度等性能。

- 加强质量控制:加强质量控制是提高纺织品耐高温黄变性能的重要保障,企业应该建立完善的质检体系,确保纺织品在使用过程中的质量稳定。

纺织品耐高温黄变是现代工业中一个重要的性能指标,它关系到产品的使用寿命和外观质量,通过了解纺织品耐高温黄变的原因、测试方法与标准以及提高纺织品耐高温黄变性能的措施等方面的内容,我们可以更好地了解纺织品耐高温黄变的问题和解决方法,我们也可以借鉴相关的案例和经验,为提高纺织品的耐高温性能提供参考和借鉴。

Articles related to the knowledge points of this article:

Shanghai Textile Expo:A Visual Introduction

The 2016 National Textile Manufacturers:An Overview