The Transformative Journey of the Textile Industry

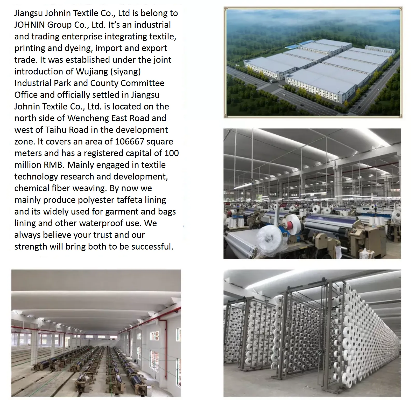

The textile industry has undergone a transformative journey in recent decades, driven by technological advancements and globalization. This transformation has led to significant changes in the industry's structure, production methods, and consumer preferences.,One of the most notable changes is the rise of digital technology, which has transformed the way textile products are produced and sold. The use of computer-aided design (CAD) software has enabled designers to create intricate patterns and designs that were previously impossible to achieve with traditional manual techniques. This has opened up new markets for innovative textile products, such as eco-friendly clothing and sustainable materials.,Another significant change is the shift towards sustainability and environmental responsibility. As consumers become more aware of the impact of their purchasing decisions on the environment, textile companies are increasingly prioritizing sustainable practices. This includes using recycled materials, reducing waste, and implementing energy-efficient production processes.,Overall, the textile industry's transformative journey has been driven by a desire for innovation, sustainability, and social responsibility. As the industry continues to evolve, it will be interesting to see how these factors shape its future development.

The textile industry, with its rich history and diverse range of products, has been a cornerstone of human civilization for centuries. From simple cotton cloths to intricate silk garments, textiles have played a crucial role in shaping our lives, from clothing to home decor, from fashion to functional materials. In this modern era, the textile industry is undergoing a transformative journey, driven by technological advancements, globalization, and changing consumer preferences. This essay will explore the key trends and challenges faced by the textile industry, as well as how it is adapting to meet the demands of the modern world.

Technological Advancements

One of the most significant trends in the textile industry is the increasing use of technology to improve efficiency, reduce costs, and enhance product quality. Machine learning and artificial intelligence are being integrated into production processes to optimize resource allocation and predict demand patterns. For example, smart sensors can monitor the condition of fabrics during the dyeing and printing process, allowing for real-time adjustments to prevent defects and save resources. Additionally, robotic weaving machines are becoming increasingly common, reducing labor costs and improving consistency in production.

Globalization and Trade

Another trend in the textile industry is the rise of global supply chains, which have made textile products more accessible to consumers around the world. As countries specialize in different stages of the production process, such as sourcing raw materials or manufacturing goods, they can benefit from economies of scale and lower costs. However, this also means that there is greater competition among suppliers and a need for better collaboration between manufacturers and retailers.

Changing Consumer Preferences

Consumer preferences are constantly evolving, with an increasing focus on sustainability, ethical sourcing, and personalized design. Sustainable textiles, such as organic cotton or recycled polyester, are becoming increasingly popular, as consumers seek out products that are environmentally responsible. Ethical sourcing practices, such as fair trade or B Corp certification, are also gaining traction, as consumers become more aware of the impact their purchases have on workers and communities. Finally, personalized design is becoming more prevalent, with customers seeking unique and customizable products that reflect their individuality.

Case Study: Nike's Innovation in Textile Technology

Nike, one of the world's largest sportswear companies, has been at the forefront of innovation in the textile industry. The company has invested heavily in research and development to develop new materials and technologies that improve performance and comfort. For example, Nike has developed a proprietary blend of polyurethane foam that provides superior cushioning and durability, making it ideal for high-performance athletic shoes. Additionally, Nike has used cutting-edge fabrics such as Lycra and Tencel to create innovative designs that are both lightweight and breathable.

Case Study: Patagonia's Sustainability Goals

Patagonia, another leading brand in the textile industry, has set ambitious sustainability goals to ensure that its products are both environmentally responsible and socially responsible. The company has committed to using only sustainably sourced materials in its clothing and gear, and has implemented measures to reduce its carbon footprint through energy conservation and waste reduction. Patagonia has also worked to support local communities in developing countries, providing job opportunities and promoting sustainable farming practices.

Conclusion

The textile industry is facing many challenges and opportunities in the modern world. While technological advancements are driving efficiency and innovation, globalization and changing consumer preferences are driving market dynamics. As brands like Nike and Patagonia demonstrate, embracing sustainability and ethical sourcing practices is essential for long-term success. By adapting to these trends and remaining committed to innovation and responsibility, the textile industry can continue to thrive and provide meaningful contributions to society.

在片染织厂纺织厂,我们见证了纺织业的魅力与力量,下面是一篇关于该厂的英文口语化内容,结合表格和案例说明,希望能为您呈现一个全面的介绍。

片染织厂概述

片染织厂位于某城市的重要工业区,是一家专注于纺织生产的工厂,该厂拥有先进的设备和技术,致力于生产高质量的纺织品,在过去的几年里,片染织厂以其高效的生产流程和出色的产品质量赢得了客户的信任和好评。

生产流程介绍

- 原料采集:片染织厂从优质的原材料供应商处采购高质量的棉花、丝绸等原料。

- 纺织加工:在纺织加工车间,经过多道工序的精细加工,将原料转化为各种类型的纺织品。

- 染色处理:染色是纺织过程中的重要环节,片染织厂采用先进的片染技术对纺织品进行染色处理,染色过程包括染色剂的添加、染色时间的控制等,确保染料的均匀分布和颜色的持久性。

- 织造工序:织造是纺织的最后一步,通过先进的织机将纺织品织成各种形状和大小。

案例分析

以某次生产为例,展示片染织厂的生产过程和特点。

- 原料采购与质量控制:该次生产中,片染织厂严格挑选优质的原材料供应商,确保原料的质量和纯度,片染织厂对原料进行严格的质量控制,确保每批产品的质量符合标准。

- 生产流程优化:为了进一步提高生产效率和质量,片染织厂对生产流程进行了优化,采用自动化设备提高生产效率,减少人工干预;采用先进的染色技术,提高染料的均匀性和颜色的持久性;加强生产过程中的质量控制,确保每一步都符合标准。

- 产品展示:该次生产的纺织品具有高质量、高档次的特点,深受客户好评,其颜色鲜艳、质地柔软、手感舒适,深受消费者喜爱。

生产工艺与设备介绍

- 生产工艺:片染织厂采用先进的片染技术,结合现代化的生产工艺,生产出高质量的纺织品,其生产工艺包括原料采集、纺织加工、染色处理和织造等环节。

- 设备介绍:片染织厂拥有先进的纺织设备和染色设备,包括全自动纺纱机、织机、染色机等,这些设备不仅提高了生产效率和质量,还保证了产品的质量和稳定性。

展望未来,片染织厂将继续致力于提高生产效率和质量,加强技术创新和研发,推动纺织行业的发展,片染织厂还将加强与客户的沟通和合作,不断提高产品的质量和竞争力。

片染织厂作为某城市的重要工业区的一员,以其先进的生产技术和高质量的产品赢得了客户的信任和好评,该厂的先进生产工艺和设备不仅提高了生产效率和质量,还保证了产品的稳定性和可靠性,在未来,片染织厂将继续致力于提高生产效率和质量,推动纺织行业的发展。

Articles related to the knowledge points of this article:

The Textile Factory in Songtao:A Cultural and Industrial Experience

Strategies for Effective Management in a Textile Factory

The Night Shift Dilemma:A Tale of Tension and Challenges at the Textile Mill