Textiles for Sustainable Energy Efficiency:A Comprehensive Guide

"Textiles for Sustainable Energy Efficiency: A Comprehensive Guide" is a comprehensive guide on the use of textiles for sustainable energy efficiency. The guide covers various types of textiles, their properties and applications in sustainable energy systems, as well as strategies for their production, use, and disposal. It also discusses the challenges and opportunities associated with the development and implementation of textiles for sustainable energy efficiency. Overall, the guide provides valuable insights and information for those interested in exploring the potential of textiles in promoting sustainable energy practices.

Introduction: In the face of global climate change and escalating energy demands, textiles play a crucial role in reducing our carbon footprint. By adopting sustainable practices in their production, consumption, and disposal, textiles can significantly contribute to achieving energy efficiency goals. This guide aims to provide insights into the latest advancements, best practices, and case studies that demonstrate how textiles can be designed and used to optimize energy use.

Textile Production: The textile industry is one of the largest contributors to greenhouse gas emissions. To reduce its environmental impact, manufacturers are turning to more sustainable methods such as using renewable energy sources like solar or wind power. For instance, the fashion brand Reformation uses 100% renewable energy to power its factories, resulting in a reduction of 95% in greenhouse gas emissions compared to traditional methods.

Textile Consumption: Consumers have an opportunity to influence textile production by choosing products made from sustainable materials. The UK-based company Bamford has created a line of clothing made entirely from organic cotton, which is grown without the use of synthetic pesticides. This not only reduces the environmental impact but also provides consumers with a higher quality product.

Textile Disposal: Textile waste often ends up in landfills, contributing to pollution and resource depletion. To address this issue, many companies are implementing circular economy principles by designing textiles that can be reused or recycled. For example, the Italian brand Missoni offers a collection of furniture pieces made from recycled polyester fabric, showcasing the potential of textiles in creating innovative and sustainable solutions.

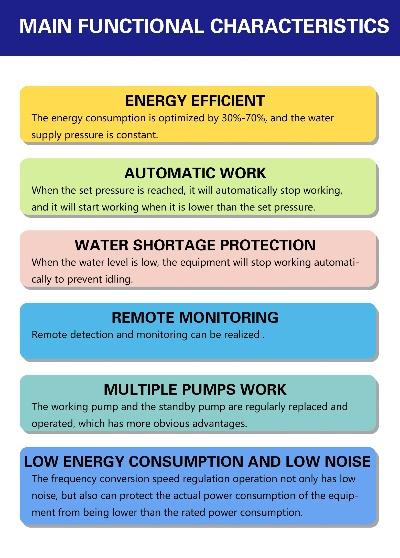

Energy Efficiency in Textile Manufacturing: The manufacturing process itself can be optimized for energy efficiency. For instance, the German company Schoeller employs a closed-loop system where waste heat from the spinning process is captured and used to preheat water for dyeing. This not only saves energy but also reduces emissions.

Textile Energy Efficiency in Use: When textiles are worn or displayed, they consume energy. Smart textiles, such as those with embedded sensors that monitor temperature and moisture levels, can help reduce energy usage. For example, the smart shirt developed by Nike allows users to adjust its temperature and moisture absorption based on their body's response.

Energy Efficiency in Textile Waste Management: Textile waste management is another area where energy efficiency can be achieved. Compostable textiles, such as bamboo or hemp fibers, can be used in composting facilities instead of plastic waste. This not only reduces the amount of waste sent to landfills but also helps to create nutrient-rich soil.

Case Studies: One notable example of textile energy efficiency is the development of "green" yarns made from wood pulp or recycled materials. These yarns are biodegradable and have a lower environmental impact compared to conventional cotton or polyester yarns. Another example is the use of LED lighting in clothing stores, which can significantly reduce energy consumption during peak hours when sales are highest.

Conclusion: By embracing sustainable practices in textile production, consumption, and disposal, we can make significant strides towards achieving energy efficiency. As demonstrated through case studies and best practices, textiles have the potential to become a cornerstone in the fight against climate change. It's time for industries to take responsibility for their environmental impact and invest in sustainable alternatives that benefit both people and the planet.

随着全球气候变化和环境问题日益严重,纺织品行业面临着巨大的挑战,为了实现可持续发展,提高纺织品的使用效率并降低能源消耗成为行业发展的关键,本文将围绕纺织品高效节能的主题展开讨论,并通过英文案例说明来进一步阐述。

纺织品高效节能的重要性

- 环境保护:减少能源消耗和碳排放有助于保护环境,减少对自然资源的过度开采和破坏。

- 经济效益:通过提高纺织品的使用效率,可以降低生产成本,提高产品质量,从而提升经济效益。

- 市场需求:随着消费者对环保和可持续性产品的需求增加,纺织品行业需要不断创新和改进,以适应这一市场需求。

纺织品高效节能的技术与实践

- 高效纤维技术:采用新型高性能纤维材料,如低能耗纤维、生物可降解纤维等,提高纺织品的耐久性和环保性能。

- 节能染整技术:采用节能染整工艺,如低温染色、无污染烘干等,减少能源消耗和环境污染。

- 案例分析:

某知名品牌通过引入高效节能的纺织生产线,实现了生产效率的提高和能源消耗的降低,该品牌采用了先进的节能染整技术,减少了染整过程中的能源消耗,提高了产品质量和客户满意度。

某地区政府推广绿色纺织政策,鼓励企业采用环保材料和生产工艺,成功降低了纺织品的碳排放和能源消耗,该地区还建立了完善的回收和处理体系,确保废旧纺织品的有效利用和资源化处理。

纺织品高效节能的实际应用与推广

- 政策支持:政府可以通过制定相关政策,鼓励纺织品行业采用高效节能技术,推动行业创新和发展。

- 宣传教育:通过宣传教育,提高消费者对纺织品高效节能的认识和重视程度,也可以通过举办相关活动,推广纺织品高效节能的产品和服务。

- 国际合作与交流:加强国际间的合作与交流,共同推动纺织品高效节能技术的发展和应用。

纺织品高效节能是行业发展的必然趋势,也是实现可持续发展和保护环境的重要手段,通过采用高效纤维技术、节能染整技术和案例分析等方法,可以实现纺织品使用效率的提高和能源消耗的降低,政府、企业和消费者都应该积极参与到纺织品高效节能的实践中来,共同推动行业创新和发展,纺织品行业需要不断创新和改进,以适应市场需求和不断提高的环保要求。

Articles related to the knowledge points of this article:

Transforming Textiles with Technological Innovation:The Journey of Rui Rong

Embracing the Global Scene:The Story of Shaoxing Qiaoyi Textiles