Textile Finishing Techniques:A Comprehensive Guide

This comprehensive guide to textile finishing techniques provides an in-depth understanding of the various methods used to enhance the appearance and performance of textile materials. The guide covers a wide range of techniques, including dyeing, printing, coating, and finishing processes such as calendering, padding, and finishing with waxes and oils. Each technique is explained in detail, along with practical tips for achieving optimal results. This guide is essential for anyone working with textiles, whether they are manufacturers, designers, or consumers, as it provides a valuable resource for selecting the right finishing process for their specific needs.

Textile finishing techniques are the processes that enhance the quality, durability, and appearance of textile products. These methods involve various chemical and physical treatments that transform raw fabric into finished goods with specific characteristics. In this guide, we will explore the fundamental techniques used in the industry and provide insights into their applications, benefits, and limitations.

Table: Textile Finishing Techniques

| Technique | Description | Application | Benefits | Limitations |

|---|---|---|---|---|

| Dyeing | The process of applying dyes to textile materials to change their color. | Clothing, upholstery, carpets | Colorfastness, washability | Can cause shrinkage or warp during processing |

| Embroidery | A decorative technique that involves stitching threads onto a fabric surface. | Apparel, home furnishings | Adds texture, pattern, and detail | May require special equipment for intricate designs |

| Printing | The use of ink or other printing mediums to create patterns on fabric. | Clothes, bags, tablecloths | Versatile design options | Can be expensive and time-consuming |

| Stamping | The application of adhesive stamps to a fabric surface to create patterns or logos. | Apparel, packaging | Versatile design tool | Can be labor-intensive and prone to wear and tear |

| Lamination | The process of bonding two or more layers of fabric together to improve strength and durability. | Shoes, bags, upholstery | Increased resistance to wear and tear | Can be costly and time-consuming |

| Heat setting | The application of heat to set the shape and texture of a fabric. | Bedding, curtains, carpets | Improves durability and reduces pilling | May affect the color and texture of the fabric |

Case Study: Textile Finishing in Fashion Industry

In the fashion industry, textile finishing plays a crucial role in creating trendy and high-quality garments. For instance, a popular technique used in the industry is digital printing, which allows designers to create intricate patterns and designs on fabrics with ease. This technique has revolutionized the fashion industry by offering endless possibilities for creativity and innovation.

Another example is the use of heat setting in the production of high-end bedding and upholstery. By using heat setting techniques, manufacturers can create durable and long-lasting products that resist pilling and fading over time. This not only enhances the aesthetic appeal of the product but also ensures customer satisfaction.

In conclusion, textile finishing techniques play a vital role in shaping the final product and enhancing its performance. From dyeing to embroidery, from printing to laminating, each technique offers unique benefits and limitations. As the fashion industry continues to evolve, it is essential for manufacturers to stay updated with the latest techniques and incorporate them into their production processes to meet the evolving demands of consumers.

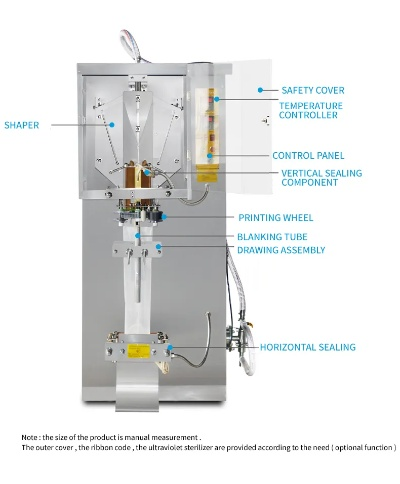

Good afternoon, this is a brief overview of what textile stamping and shaping technologies are and their applications. Let's delve into this topic.

纺织品定形技术概述

纺织品定形技术是一种涉及材料加工和成型的技术,主要用于改变或塑造纺织材料的形状和外观,它涵盖了多种工艺方法,包括但不限于压花、印花、烫印、织造后整理等,这些技术能够根据设计需求,通过改变纤维排列、增加纤维密度或改变纤维材质等方式,实现对纺织品形状的精确塑造。

技术原理与关键步骤

-

原理:纺织品定形技术主要依赖于机械压力和热处理等手段,通过施加压力和温度控制,改变纤维的形态和结构,从而达到塑造纺织品的形状和外观的目的。

-

关键步骤:

- 材料准备:选择合适的纺织材料,并进行必要的预处理,如清洗、干燥等。

- 模具设计:根据设计需求,设计合适的模具,确保形状的精确复制。

- 压力和温度控制:通过压力机和温度控制系统,施加适当的压力和温度,对纤维进行塑形。

- 后处理:对塑形后的纺织品进行必要的后处理,如烘干、定型等,以达到所需的外观效果。

技术应用与案例分析

-

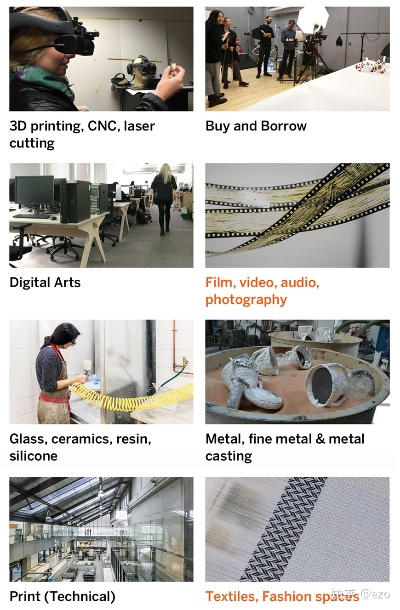

应用领域:纺织品定形技术广泛应用于服装、家居装饰、工业制品等领域,印花技术可以用于制作各种图案的纺织品,压花技术可以用于制作具有特殊纹理的纺织品。

-

案例分析:

- 服装行业案例:某品牌在推出新款服装时,采用了纺织品定形技术中的印花技术,成功塑造了时尚的图案效果,吸引了大量消费者的关注。

- 家居装饰案例:家居用品制造商使用纺织品定形技术中的织造后整理工艺,对纺织品进行特殊处理,使其具有更好的质地和外观效果,提高了产品的附加值。

技术应用与未来发展

随着科技的不断进步和人们对纺织品品质要求的提高,纺织品定形技术也在不断发展和创新,该技术将更加注重智能化、自动化和个性化,能够更好地满足人们对于纺织品品质和外观的要求,该技术也将更加注重环保和可持续性,减少对环境的影响。

纺织品定形技术是一种重要的纺织加工技术,它能够实现对纺织材料的精确塑造和美化,通过合理的工艺方法和设备选择,该技术能够满足不同领域的需求,提高纺织品的品质和附加值,该技术的发展也将推动纺织行业的创新和发展。

Articles related to the knowledge points of this article:

高阳方杰纺织品公司招聘启事 Your Next Career Step

The Fabrics of Seamless Luxury

Introduction to the Fabric Ingredient Adhesive

The Story of Double Connect Textiles:A Multinational Textile Company