The Impact of Same-Batch Color Variations on Textile Products

Introduction In the textile industry, color is a critical aspect that directly affects consumer perception and brand image. However, due to the complexities involved in dyeing and printing processes, there is often a discrepancy between what is seen in the factory and what is presented to customers. This phenomenon is known as "same-batch color variations" or "color inconsistency." In this article, we will discuss the causes of color variations, their impact on consumers, and how they can be minimized.

Causes of Same-Batch Color Variations

- Dye Lots: Different dye lots may produce different shades or colors when exposed to similar conditions.

- Printing Techniques: Different printing techniques can result in variations in color intensity and hue.

- Material Variations: Changes in fabric composition, such as fiber type or thread count, can affect the final shade.

- Environment: Lighting conditions, temperature fluctuations, and air pollution can affect the color appearance of the finished product.

- Machine Settings: Differences in machine settings, including tension, speed, and pressure, can cause color shifts.

- Quality Control: Poor quality control measures can lead to uneven dye application or improper printing.

- Shipping Conditions: Long-distance shipping can cause color fading or discoloration due to exposure to light and humidity.

Impact of Same-Batch Color Variations

- Consumer Dissatisfaction: Variations in color can lead to dissatisfaction among customers, who may perceive the product as subpar or inferior.

- Brand Image: A consistent color theme across all products can enhance a brand's image and make it more recognizable.

- Reputational Risk: If color variations are not addressed promptly, they can damage a company's reputation by creating doubt about its product quality.

- Legal Compliance: Some industries, such as cosmetics, require strict adherence to color standards to ensure safety and efficacy.

Minimizing Same-Batch Color Variations

- Developing Standardized Processes: Ensure that every step of the manufacturing process is standardized to minimize variability.

- Conducting Quality Control Tests: Regularly inspecting and testing products for color consistency can help identify and correct issues early on.

- Using Advanced Technology: Adopting advanced printing and dyeing technologies can improve accuracy and reduce the likelihood of color variations.

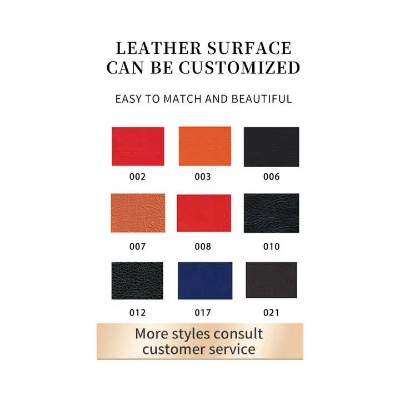

- Providing Customer Service: Providing clear communication about color variations and offering solutions to address any concerns can build trust with customers.

- Investing in Quality Assurance: Investing in quality assurance personnel and tools can help detect and prevent color variations before they reach the customer.

Case Study: Failure to Address Same-Batch Color Variations In the fashion industry, a major brand experienced significant backlash after a popular collection was released with noticeable color variances from previous seasons. Customers were upset because they expected the same level of quality across all products. The brand had to issue a recall and offer refunds to customers affected by the color variations. This incident highlighted the importance of addressing and minimizing color variations to maintain consumer trust and loyalty.

Conclusion The issue of same-batch color variations in textile products cannot be ignored, as it has a direct impact on consumer perception, brand image, and reputation. By understanding the causes of color variations, implementing effective quality control measures, and adopting advanced technology, manufacturers can minimize these issues and provide a consistent and high-quality product experience to their customers. Remember, the success of any textile product lies not only in its aesthetic appeal but also in its ability to meet and exceed consumer expectations.

背景介绍

纺织品同批次色差问题是一个常见而又复杂的话题,在纺织品生产和销售过程中,由于各种因素的影响,可能会出现色差问题,这不仅影响消费者的购物体验,还可能影响到品牌形象和市场竞争力。

色差现象分析

色差现象可以通过多种因素引起,例如原材料差异、生产工艺差异、环境因素等,在纺织品行业中,不同批次的产品可能因为原材料、染料、工艺流程等因素存在色差,不同地区、不同厂家生产的产品也可能因为地理环境、生产工艺等因素导致色差。

案例说明

为了更好地说明纺织品同批次色差问题,我们可以举一个英文案例,假设有一家纺织品制造商,近期发现其生产的某些批次纺织品存在色差问题,为了更好地了解这一情况,我们可以参考以下表格进行详细说明:

【案例表格】

| 参数 | 描述 | 同批次产品色差情况 |

|---|---|---|

| 原材料 | 使用了高质量的天然纤维和化学染料 | 色差不明显 |

| 生产过程 | 采用先进的生产工艺和技术标准 | 色差存在,但程度可控 |

| 环境因素 | 受到特定地区气候的影响 | 色差较为明显 |

| 市场反馈 | 部分消费者反映色差问题影响购买体验 | 消费者满意度有所下降 |

在这个案例中,我们可以看到色差现象是由多种因素引起的,原材料的差异可能是导致色差的主要原因之一,生产工艺的差异、环境因素等也可能对色差产生影响,这些因素可能导致纺织品在生产过程中出现色差问题,从而影响产品的质量和消费者的购物体验。

讨论与建议

针对纺织品同批次色差问题,我们可以通过以下方式讨论并提出建议:

- 加强质量控制:加强原材料采购和质量控制,确保原材料来源可靠,减少因原材料差异导致的色差问题,加强生产工艺控制,采用先进的生产工艺和技术标准,提高产品质量和一致性。

- 加强市场监管:加强市场监管力度,对出现色差问题的产品进行调查和处理,对于存在严重色差问题的产品,应采取召回或停止销售等措施,维护品牌形象和市场竞争力。

- 提高消费者意识:提高消费者对纺织品质量的认识和鉴别能力,通过宣传和教育,让消费者了解纺织品同批次色差问题的原因和影响,提高消费者的购买信心和满意度。

- 寻求技术支持:寻求技术支持,加强与科研机构的合作,研究解决纺织品同批次色差问题的技术和方法,通过科技创新,提高纺织品生产的质量和一致性,降低色差问题对产品的影响。

纺织品同批次色差问题是纺织品生产和销售过程中常见而又复杂的问题,为了解决这一问题,我们需要从多个方面入手,加强质量控制、加强市场监管、提高消费者意识、寻求技术支持等,我们也需要加强对纺织品质量的认识和鉴别能力,让消费者了解纺织品同批次色差问题的原因和影响,提高消费者的购买信心和满意度。

Articles related to the knowledge points of this article:

The Dynamics of the KAIXIN Textile Industry in Guangzhou

Export Tax Rates in Korea A Guide to Ensure Compliance and Maximize Profits

Navigating the Global Fabrics:The Journey of Jiangyin Jinti Textiles