Pestle and Spoke:Understanding Pestel in Textile Industry

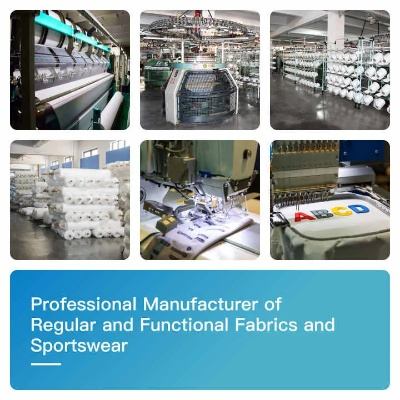

Pestle and Spoke:Understanding Pestel in Textile Industry,Pestle and Spoke is a term used in the textile industry to describe the process of removing excess water from wet fabric. This process is essential for maintaining the quality and consistency of the fabric, as well as preventing mold and mildew growth. The pestle and spoke technique involves using a rotary drum with multiple spokes that rotate around a central shaft, which forces the fabric through the drum. This method allows for efficient and even water removal, resulting in a more uniformly dried fabric.,In addition to its practical applications, understanding the pestle and spoke technique also has implications for the sustainability of the textile industry. By optimizing the drying process, manufacturers can reduce waste and energy consumption, leading to more sustainable practices. Overall, the pestle and spoke technique is an important aspect of the textile industry, providing both practical benefits and environmental considerations.

Introduction: The textile industry is a vast field that encompasses the production of various materials used for clothing, footwear, home furnishings, and other applications. Among these materials, pestle and spoke are two critical components that play a vital role in the manufacturing process. In this article, we will delve into the meaning of pestle and its significance in the textile industry, as well as provide an overview of its application in different textile products.

Pestle in Textiles: Pestle is a term commonly used in the textile industry to refer to a type of yarn or fabric made from cotton, linen, or similar natural fibers. It is characterized by its soft texture, breathability, and ability to absorb sweat. The word "pestle" comes from the Latin word "pestellum," which means "cotton."

Types of Pestle: There are several types of pestles available in the textile industry, each with its unique properties and applications. Some common types of pestles include:

-

Cotton Pestle: This is the most common type of pestle used in the textile industry. It is soft, breathable, and absorbent, making it ideal for use in clothing, bedding, and other textile products.

-

Linen Pestle: Linen is another popular choice for pestle fabrics. It is stronger than cotton, durable, and resistant to wrinkling. Linen pestles are often used in outdoor wear and sportswear.

-

Silk Pestle: Silk is a luxurious material that is highly prized for its softness, smoothness, and luster. Silk pestles are typically used in high-end fashion and accessories.

-

Wool Pestle: Wool is a natural fiber that is known for its warmth and comfort. Wool pestles are often used in winter clothing, blankets, and other textile products.

Application of Pestle in Textiles: Pestles are used in various textile products to enhance their performance and appearance. Here are some examples of how pestles are applied in different textile products:

-

Clothing: Pestles are used in the production of shirts, dresses, pants, and other garments. They provide comfort and breathability, making them ideal for everyday wear.

-

Bedding: Pestle fabrics are widely used in the production of bedsheets, pillowcases, and other bedding items. They offer a comfortable sleep experience and help regulate body temperature.

-

Home Furniture: Pestles are also used in the production of furniture such as sofas, chairs, and beds. They add style and elegance to the interior design while providing comfort and durability.

-

Sportswear: Pestle fabrics are often used in the production of athletic apparel such as tracksuits, swimwear, and gym wear. They are designed to wick away sweat and keep the wearer cool and dry.

-

Accessories: Pestle fabrics are also used in the production of hats, scarves, bags, and other accessories. They offer a unique look and feel that sets them apart from other materials.

Conclusion: In conclusion, pestles are a crucial component of the textile industry that play a vital role in enhancing the performance and appearance of various textile products. From clothing to bedding, home furnishings, sportswear, and accessories, pestles have found a place in almost every aspect of our lives. As technology continues to advance, we can expect to see more innovative uses for pestles in the future, providing even greater value and convenience to our daily lives.

在纺织品的世界里,PES(聚乙烯)是一个重要的组成部分,我们就来深入探讨一下这个在纺织品中不可或缺的成分。

PES的基本概念

PES是一种由乙烯为主要原料经过聚合反应得到的聚合物,它在纺织行业中广泛应用,用于制作各种面料、纱线、织物等,PES具有优良的耐热性、抗老化性、抗紫外线性能,同时还具有优良的弹性和耐磨性。

PES在纺织品中的应用

- 面料制造:PES面料以其优良的耐热性、抗老化性、抗紫外线性能,广泛应用于服装、家居用品等领域,运动服、户外装备、床上用品等。

- 纱线与织物:PES纱线因其良好的延伸性和柔软性,常用于制作纱线、毛巾、床单等,PES织物因其独特的纹理和性能,也广泛应用于各种包装材料、窗帘布等。

案例说明

以纺织品中的PES为例,我们可以看到它在不同领域的应用。

服装行业

在服装行业中,PES面料因其优良的耐热性、抗老化性,常被用于制作夏季服装、运动服装等,由于其柔软性和延伸性,使得服装穿着更加舒适,同时也具有很好的抗皱性能。

家居用品行业

在家居用品行业中,PES纱线因其良好的柔软性和延伸性,常被用于制作窗帘布、毛巾等家居用品,由于其环保和耐用性,使得家居用品更加环保和健康。

表格补充说明

以下是关于PES在纺织品中的表格补充说明:

| 项目 | PES在纺织品中的应用 | 相关数据或案例 |

|---|---|---|

| 主要成分 | 聚乙烯 | 主要由乙烯聚合而成 |

| 性能特点 | 优良耐热性、抗老化性、抗紫外线性能 | 在纺织行业中广泛应用 |

| 应用领域 | 面料制造、纱线与织物、服装、家居用品等 | 如运动服、户外装备、床上用品等 |

| 应用实例 | 服装行业中的夏季服装、运动服装等 | 如某品牌夏季运动服采用PES面料制作 |

| 纱线与织物特性 | 良好的延伸性和柔软性 | 如PES纱线制作的纱线柔软且具有很好的抗皱性能 |

| 其他应用领域 | 包装材料、窗帘布等 | 如环保包装材料和窗帘布等 |

PES在纺织品中扮演着重要的角色,它具有优良的耐热性、抗老化性、抗紫外线性能,同时还具有优良的弹性和耐磨性,在纺织行业中,PES的应用非常广泛,从面料制造到纱线与织物,再到服装和家居用品等领域都有涉及,随着纺织行业的发展,相信PES在纺织品中的应用将会更加广泛和深入。

Articles related to the knowledge points of this article:

Exploring the Naxi-Style Cotton Textile Wholesale Market in仁寿