Exploring the Global Market for Imported Textile Welding Services in Nanjing

This article explores the global market for imported textile welding services in Nanjing. The research focuses on the current state of the industry and its future prospects, as well as the challenges and opportunities that it faces. The analysis also includes a discussion of the factors that influence the demand for such services, including economic growth, technological advancements, and changes in consumer preferences. The study concludes by suggesting potential strategies for improving the competitiveness of the local industry and increasing its share of the global market. Overall, the findings highlight the importance of investing in the development of domestic textile welding services to ensure long-term success in the increasingly competitive global market.

Introduction: In today's globalized world, the textile industry is a vital sector that connects nations and cultures. As demand for high-quality imported textiles continues to grow, the importance of efficient and reliable welding services cannot be overstated. In Nanjing, one city that has made significant strides in this field is China's capital. With a thriving economy and a growing market for imported textiles, Nanjing offers a prime opportunity for businesses looking to expand their operations or upgrade their existing processes. In this article, we will explore the key aspects of imported textile welding services in Nanjing and provide an overview of some successful cases.

Welding Services in Nanjing: A Comprehensive Guide Nanjing is home to a number of specialized welding companies that specialize in the processing of imported textiles. These companies employ a range of techniques to ensure that the welded parts meet stringent quality standards. Some of the most popular welding methods used in Nanjing include but are not limited to:

-

Resistance Welding: This method involves using a high-current electrical current to melt the metal together. It is commonly used for welding steel and aluminum, making it ideal for connecting pipes and other metal components.

-

Tungsten Inert Gas (TIG) Welding: This technique uses a non-consumable tungsten electrode to create a shielding gas atmosphere that prevents oxidation and contamination. It is commonly used for welding stainless steel and other high-grade materials.

-

Laser Welding: This method involves using a laser beam to heat up the material being welded and fuse it together. It is particularly effective for joining thin materials like foils and films.

-

MIG/MAG Welding: This method uses an electric arc to melt the base metal and filler wire together. It is commonly used for welding carbon steel and mild steel.

Key Factors to Consider When Selecting Welding Services in Nanjing: When selecting welding services in Nanjing, it is essential to consider several factors to ensure that you choose the right company for your needs. Here are some key factors to consider:

-

Experience: Look for companies with extensive experience in the welding industry, especially those that have worked on similar projects as yours. This will help you avoid potential pitfalls and ensure that the welding process is completed efficiently and effectively.

-

Qualifications: Ensure that the welding company has the necessary qualifications and certifications required by your industry. This will help you ensure that the welders are trained and experienced in handling your specific materials and applications.

-

Quality Control: Check if the welding company has strict quality control measures in place. This includes regular inspections and testing of the welded parts to ensure that they meet your specifications and standards.

-

Cost-Effectiveness: Evaluate the cost-effectiveness of the welding services offered by different companies. Consider the overall cost of labor, equipment, and materials, as well as any additional fees associated with the service.

-

Customer Service: Choose a company that provides excellent customer service. This includes responsiveness, communication, and availability to address any issues or concerns that may arise during the project.

Example Case Study: One successful case study in Nanjing involved a textile manufacturer who needed to replace old welding equipment with new, more efficient models. The manufacturer approached several welding companies in Nanjing to find the best solution for their needs. After evaluating various options, they decided to work with a local company specializing in resistance welding.

The manufacturer provided the company with detailed specifications for the welding process, including the type of metal being welded, the thickness of the material, and any special requirements for the welded parts. The company developed a customized welding plan that took into account the manufacturer's production schedule and budget.

The welding company then began working on the project, using state-of-the-art equipment and techniques to ensure that the welded parts met all of the manufacturer's specifications. The result was a seamless integration of the new welding equipment into the manufacturer's production line, resulting in improved efficiency and reduced downtime.

Conclusion: Imported textile welding services in Nanjing offer a wide range of benefits for businesses looking to enhance their production capabilities. By choosing a reputable welding company that specializes in resistance welding, you can ensure that your imported textiles are processed efficiently and effectively. With careful consideration of factors such as experience, qualifications, quality control, cost-effectiveness, and customer service, you can find the perfect partner for your next project.

背景介绍

南京作为我国的重要城市,近年来进口纺织品行业蓬勃发展,进口纺织品焊接加工作为贸易的重要环节,不仅促进了国内外市场的交流与合作,也为当地经济发展注入了新的活力,本文将围绕南京进口纺织品焊接加工的主题,从多个方面进行深入探讨。

南京进口纺织品焊接加工概述

进口纺织品类型与来源

南京进口的纺织品主要来源于全球各地的优质原材料,包括但不限于棉、麻、丝、毛等,这些纺织品经过严格的检验和质量控制,确保符合国际标准。

焊接加工技术与应用

南京地区的纺织品焊接加工采用先进的焊接技术,能够满足不同材质和尺寸的纺织品焊接需求,焊接加工不仅提高了纺织品的强度和耐用性,还提高了产品的美观度和功能性。

行业发展趋势与挑战

随着全球贸易的深入发展,南京进口纺织品焊接加工行业面临着越来越多的机遇和挑战,行业需要不断提高技术水平,优化生产流程,以满足市场需求,还需要加强国际合作与交流,提高行业整体竞争力。

案例分析

为了更好地了解南京进口纺织品焊接加工的实际操作和效果,我们以一个具体的案例进行分析。

某品牌纺织品进口与焊接加工

该品牌进口的纺织品主要来源于东南亚地区,经过南京地区的焊接加工后,产品质量得到了显著提升,焊接加工采用了先进的焊接技术,能够满足不同材质和尺寸的纺织品焊接需求,该品牌还注重产品的环保和可持续性,确保产品的质量和环保标准符合国际标准。

技术说明与图表补充

技术说明:

焊接技术简介

南京地区的纺织品焊接加工采用先进的焊接技术,包括电阻焊、激光焊等,这些技术能够满足不同材质和尺寸的纺织品焊接需求,提高了纺织品的强度和耐用性,焊接加工还具有环保、高效、美观等优点。

图表补充:

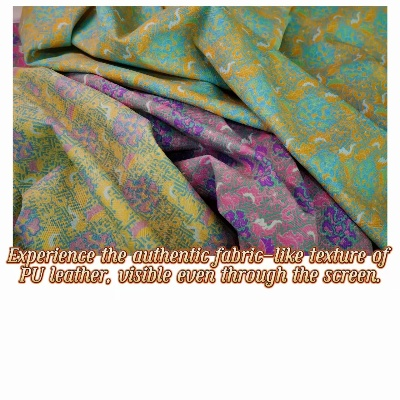

以下为南京地区纺织品焊接加工技术的相关图表:

(请在此处插入图表)

未来展望与建议

未来展望:

随着全球贸易的深入发展,南京进口纺织品焊接加工行业将继续保持繁荣发展态势,行业需要不断提高技术水平,优化生产流程,以满足市场需求,还需要加强国际合作与交流,提高行业整体竞争力,行业还需要注重产品质量和环保标准,推动绿色、可持续的发展。

建议:

(1)加强技术研发和创新,推动行业转型升级。 (2)加强国际合作与交流,拓展市场渠道。 (3)注重产品质量和环保标准,提高品牌影响力。 (4)加强行业监管和管理,保障市场秩序和公平竞争。

南京进口纺织品焊接加工作为贸易的重要环节,对于促进国内外市场交流与合作、推动当地经济发展具有重要意义,行业需要继续加强技术研发和创新,提高产品质量和环保标准,推动绿色、可持续的发展,还需要加强国际合作与交流,提高行业整体竞争力。

Articles related to the knowledge points of this article: