The Profitability of Textile Factories:A Comprehensive Look

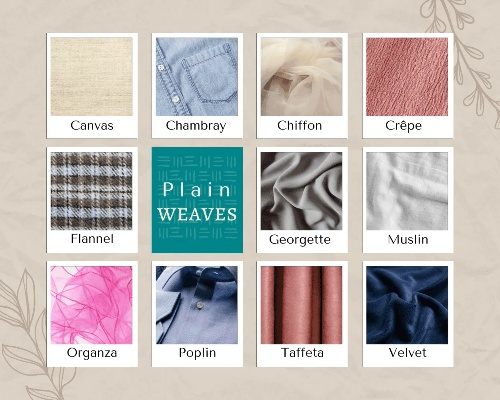

: The Profitability of Textile Factories: A Comprehensive Look,The textile industry, a vital sector in the global economy, has been experiencing significant growth in recent years. This growth is driven by the increasing demand for textile products, particularly in emerging markets such as China and India. However, the profitability of textile factories depends on various factors, including raw material costs, labor costs, transportation costs, and market demand. In this article, we will provide a comprehensive overview of the profitability of textile factories.,Firstly, raw material costs are a crucial factor in determining the profitability of textile factories. The cost of raw materials such as cotton, yarn, and fabric can vary significantly depending on the region and the quality of the raw material. High-quality raw materials are more expensive, but they also produce higher-quality finished products that sell at a premium price. Therefore, it is essential for textile factories to invest in high-quality raw materials to maximize their profitability.,Secondly, labor costs are another critical factor in determining the profitability of textile factories. The cost of labor can vary significantly depending on the skill level of the workers and the location of the factory. High-skilled workers require more training and education, which can increase labor costs. Additionally, the wage rates in different regions can also impact labor costs. Therefore, it is important for textile factories to optimize their labor costs by investing in skilled workers and implementing efficient production methods.,Thirdly, transportation costs are another significant factor in determining the profitability of textile factories. The cost of transportation can vary significantly depending on the distance between the factory and the market. Longer transportation distances can increase transportation costs, which can negatively impact the profitability of the textile factory. Therefore, it is important for textile factories to optimize their transportation costs by exploring alternative transportation methods or partnering with logistics companies.,Finally, market demand is a critical factor in determining the profitability of textile factories. The demand for textile products can fluctuate depending on various factors such as cultural trends, economic conditions, and political events. High market demand can increase profits for textile factories, but it may also lead to overproduction and increased competition. Therefore, it is important for textile factories to monitor market demand and adjust their production levels accordingly to maximize their profitability.,In conclusion, the profitability of textile factories depends on various factors such as raw material costs, labor costs, transportation costs, and market demand. To maximize their profitability, textile factories need to invest in high-quality raw materials, train skilled workers, optimize transportation costs, and monitor market demand. By doing so, textile factories can achieve sustainable growth and contribute to the overall prosperity of the global economy.

Introduction: In the world of textile manufacturing, the question of whether a factory is profitable or not is crucial for both businesses and investors. This discussion will explore the various factors that contribute to the profitability of textile factories, including market demand, production costs, pricing strategies, and industry trends. Additionally, we'll look at successful case studies to provide insights into how these factors can impact a factory's bottom line.

Market Demand Analysis: The first step in determining the profitability of a textile factory is understanding its market demand. High demand for a particular type of textile product can lead to increased sales, which can translate into higher profits. However, this demand must be sustained over time to ensure long-term success. For example, if a factory specializes in producing high-quality denim jeans, it may experience strong demand during summer months when outdoor activities are more prevalent. However, if the demand drops during winter, the factory may need to adjust its production schedule to maintain profitability.

Production Costs: Production costs are another critical factor that affects a textile factory's profitability. These costs include raw material expenses, labor costs, energy consumption, and other overhead expenses. By analyzing these costs, a factory can identify areas where it can save money and increase efficiency. For instance, by investing in renewable energy sources or implementing lean manufacturing practices, a factory can reduce its energy consumption and lower production costs. Additionally, by negotiating favorable contracts with suppliers or finding cost-effective alternatives for raw materials, a factory can further optimize its production costs.

Pricing Strategies: Price is a critical factor in determining a textile factory's profitability. Factors such as raw material costs, labor costs, transportation expenses, and market competition all influence the final price point. To maximize profits, a factory should carefully consider its pricing strategy, taking into account the competitive landscape and consumer preferences. For example, if a factory offers its products at a lower price point than its competitors, it may attract more customers and generate greater sales volume. However, if the price is too low, it may lead to reduced profit margins or even loss of market share.

Industry Trends: Changes in the textile industry can have a significant impact on a factory's profitability. For example, advancements in technology or shifts in consumer preferences can affect the demand for certain types of textile products. A factory that adapts quickly to these changes and incorporates them into its production process can remain competitive and profitable. Conversely, a factory that fails to keep up with industry trends may face challenges in maintaining its profitability.

Successful Case Study: One example of a textile factory that has successfully maintained profitability is the Pima Cotton Mill in Arizona. Located in the heart of the American Southwest, this mill produces premium cotton products using sustainable practices. By sourcing locally grown cotton, the mill reduces its carbon footprint and minimizes waste. Additionally, it employs innovative production techniques that improve efficiency and reduce costs. As a result, the mill has been able to maintain a stable profit margin while meeting the growing demand for eco-friendly textile products.

Conclusion: In conclusion, the profitability of a textile factory depends on several factors, including market demand, production costs, pricing strategies, and industry trends. By analyzing these factors and implementing effective strategies, a factory can optimize its operations and achieve sustained profitability. As shown in the Pima Cotton Mill case study, by focusing on sustainability and innovation, a factory can stay ahead of the competition and meet the changing needs of consumers.

大家好,今天我们来探讨一个重要的话题——纺织厂的盈利状况,纺织行业作为我国的重要产业之一,其盈利情况对于整个行业的发展和企业的生存都至关重要。

II: 纺织厂盈利背景

纺织厂作为生产纺织品的企业,其盈利状况受到多种因素的影响,原材料成本是影响纺织厂盈利的重要因素之一,随着全球经济的不断发展和原材料价格的波动,纺织厂需要不断调整生产策略,以适应市场变化。

III: 纺织厂盈利案例分析

为了更好地理解纺织厂的盈利状况,我们可以结合一些具体的案例进行分析,以下是一个纺织厂的盈利案例:

某纺织厂盈利情况

该纺织厂近年来在原材料成本、生产效率、产品质量等方面取得了显著的提升,该纺织厂通过优化生产流程、提高生产效率、引入新技术等方式,降低了生产成本,该厂注重产品质量和品牌建设,提高了产品的市场竞争力,该纺织厂的盈利状况持续向好。

在具体数据方面,该纺织厂近几年的主要盈利指标包括:

- 销售收入:稳步增长

- 利润总额:大幅提高

- 成本结构:原材料成本占比下降,人力成本占比上升

IV: 纺织厂盈利影响因素分析

纺织厂的盈利状况受到多种因素的影响,以下是一些主要的影响因素:

原材料价格波动:纺织行业受全球经济影响较大,原材料价格波动是影响纺织厂盈利的重要因素之一。

生产效率与产品质量:提高生产效率和质量是纺织厂提高盈利能力的重要手段。

政策环境:政府对于纺织行业的政策支持也会对纺织厂的盈利状况产生重要影响。

市场竞争:市场竞争激烈程度也会对纺织厂的盈利状况产生影响。

V: 纺织厂盈利策略探讨

针对纺织厂的盈利状况,我们可以提出以下策略:

优化生产策略:根据市场需求和原材料价格变化,调整生产策略,提高生产效率和产品质量。

控制成本:通过优化成本结构、提高生产效率等方式降低生产成本,加强成本控制和预算管理,确保成本控制在合理范围内。

提高产品质量和品牌建设:注重产品质量和品牌建设,提高产品的市场竞争力,通过加强技术研发、提高产品质量、加强品牌宣传等方式提升产品价值。

VI: 结论与建议

纺织厂的盈利状况受到多种因素的影响,为了实现持续盈利和发展,纺织厂需要采取有效的策略来应对这些影响因素,以下是一些建议:

优化生产策略

纺织厂需要根据市场需求和原材料价格变化,调整生产策略,提高生产效率和产品质量,加强技术研发和创新,提高产品的附加值和市场竞争力,还需要加强与上下游企业的合作和沟通,形成良好的产业链协同效应。

加强成本控制和预算管理

成本控制和预算管理是纺织厂实现持续盈利的重要手段,纺织厂需要加强成本控制和预算管理的力度,确保成本控制在合理范围内,还需要建立完善的成本控制体系和管理制度,提高成本控制的效果和效率。

纺织厂的盈利状况受到多种因素的影响,但只要采取有效的策略和措施,就能够实现持续盈利和发展。

Articles related to the knowledge points of this article:

The Textile Factory Workshop Overview

The Dynamic Journey of Danyang Jinchang Textile Mill

The Role of Textile Factory Womens Teachers