Effective Use of Dyeing Agents in Hebei Textile Industry

Dyeing agents are an essential component of the textile industry, and their effectiveness can significantly impact the quality and performance of finished products. In the Hebei textile industry, dyeing agents play a crucial role in achieving vibrant colors and enhancing the durability of fabrics.,To achieve optimal results, it is important to choose dyeing agents that are compatible with the specific fibers and dyes used in the production process. This requires thorough research and testing to determine the appropriate agent for each application.,In addition to compatibility, the effectiveness of dyeing agents also depends on their concentration and dosage. Proper adjustment of these parameters can help ensure uniform color coverage and minimize any undesirable effects such as bleeding or fading.,Overall, the effective use of dyeing agents in the Hebei textile industry requires careful consideration of various factors, including compatibility, concentration, and dosage. By following best practices and utilizing the latest technology, manufacturers can produce high-quality products that meet the demands of consumers and industry standards.

Introduction: The textile industry is one of the most crucial sectors in China, contributing significantly to its economy. Among various processes involved in textile manufacturing, dyeing is a critical step that involves applying colorants to fabrics to produce desired patterns and shades. In the dyeing process, the choice of dyeing agent plays a vital role in achieving uniform coloration across the fabric, ensuring quality control and product consistency. This article will discuss the importance of using proper amounts of dyeing agents in the Hebei textile industry, including an overview of the challenges faced by the industry, the benefits of using dyeing agents effectively, and practical examples of successful applications.

Challenges Faced by the Hebei Textile Industry: In the Hebei region, where the textile industry is highly developed, there are several challenges associated with dyeing processes. One major challenge is achieving uniform coloration across different types of fabrics, such as cotton, silk, and wool. Variations in fabric structure and composition can affect the absorption and distribution of dyestuffs, leading to uneven shades or discoloration. Another challenge is maintaining consistent color throughout the entire production process, from dye preparation to finishing stages. Poor dyeing techniques can result in faded colors, poor color fastness, and reduced product lifespan. Additionally, environmental concerns have become increasingly important, and the use of harmful chemicals in dyeing processes has led to calls for more sustainable practices.

Benefits of Using Proper Amounts of Dyeing Agents: To overcome these challenges, it is crucial to use dyeing agents effectively. Proper usage of dyeing agents ensures uniform coloration across different fabrics and maintains consistent color throughout the production process. The following table outlines the recommended dyeing agent dosages for different fabric types in the Hebei textile industry:

| Fabric Type | Recommended Dosage (g/L) |

|---|---|

| Cotton | 10-20 |

| Silk | 5-10 |

| Wool | 10-20 |

Using the right amount of dyeing agent not only enhances the aesthetic appeal of the fabric but also improves the overall quality and durability of the product. Properly balanced dyestuffs ensure even distribution and faster absorption, resulting in brighter colors and improved washability. Moreover, reducing the amount of dye used helps to minimize waste and conserve resources, making the dyeing process more environmentally friendly.

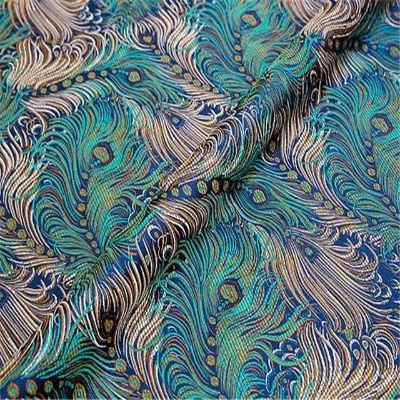

Practical Examples of Successful Applications: One example of successful application of dyeing agents in the Hebei textile industry is the use of eco-friendly dyes. Many companies have adopted natural dyes derived from plant extracts or minerals, such as indigo, madder, and turmeric. These dyes offer similar colors to synthetic dyes but are much more sustainable and biodegradable. By using these eco-friendly dyes, manufacturers can reduce their carbon footprint and comply with regulations on environmental protection.

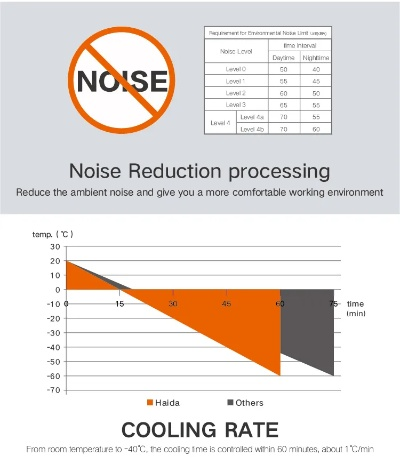

Another example is the use of advanced dyeing technologies, such as ultrasonic welding and microwave treatment. These methods can improve the adhesion between fibers and dyestuffs, resulting in a more uniform and durable color pattern. Additionally, they can shorten the dyeing time and increase productivity, saving both labor and materials.

Conclusion: In conclusion, the effective use of dyeing agents is crucial for achieving uniform coloration and maintaining consistent color throughout the Hebei textile industry. Adopting eco-friendly dyes and utilizing advanced dyeing technologies can further enhance the quality and sustainability of the products. As the industry continues to evolve, it is essential to stay updated with new developments in dyeing techniques and adopt innovative solutions that cater to the changing demands of consumers and regulatory bodies. By doing so, the Hebei textile industry can thrive in the competitive global market while preserving its heritage and commitment to sustainability.

在纺织生产过程中,匀染剂的使用量直接影响到产品质量和效率,河北地区作为纺织业的重要基地,其纺织品匀染剂用量问题备受关注,本文将围绕河北纺织品匀染剂用量展开讨论,并结合实际案例进行分析。

河北纺织品匀染剂用量概述

匀染剂种类与用量

河北地区的纺织品匀染剂主要采用有机染料进行染色处理,根据不同的纺织品类型和工艺要求,匀染剂的用量有所不同,对于棉质纺织品,通常采用较低的匀染剂用量;而对于丝绸等高档纺织品,则需要更高的匀染剂用量以确保色泽均匀和质地优良。

影响因素

影响纺织品匀染剂用量的因素主要包括纺织品类型、工艺要求、染料类型和染色条件等,在河北地区,还需考虑当地气候、原料成本等因素对匀染剂用量的影响。

实际案例分析

以某纺织企业为例,该企业采用河北地区的纺织品匀染剂进行染色处理,以下是实际案例分析:

案例背景

该企业主要生产各类棉质纺织品,其产品种类繁多,不同产品对匀染剂用量的要求也有所不同。

匀染剂使用量确定过程

该企业在确定匀染剂使用量时,首先根据纺织品类型和工艺要求进行评估,然后考虑当地气候、原料成本等因素,经过多次试验和调整,最终确定了合适的匀染剂用量。

英文表格补充说明

以下是关于河北纺织品匀染剂用量的英文表格补充说明:

| 项目 | 用量描述 | 单位 | 举例说明 |

|---|---|---|---|

| 纺织品类型 | 如棉质、丝绸等 | 单位:克/平方米 | 根据产品类型和工艺要求确定 |

| 工艺要求 | 如需达到特定色泽、质地等 | 染色标准 | 根据工艺要求确定匀染剂用量 |

| 染料类型 | 有机染料 | 如活性艳蓝、分散蓝等 | 根据纺织品类型和工艺要求选择合适的染料 |

| 当地气候条件 | 如温度、湿度等 | 如夏季高温、冬季低温等 | 根据当地气候条件调整匀染剂用量 |

| 原料成本 | 如原材料价格波动等 | 如元/千克等 | 综合原料成本考虑匀染剂用量 |

结论与建议

河北纺织品匀染剂用量需要根据纺织品类型和工艺要求进行评估,同时考虑当地气候、原料成本等因素,在实际生产过程中,应注重控制匀染剂的用量,以达到最佳的染色效果和质量,还应加强技术研究和创新,提高匀染剂的利用率和染色效率,建议相关企业在生产过程中加强质量控制和管理,确保产品质量和安全。

Articles related to the knowledge points of this article:

The Status of Ningde Textiles:A Look at Market Changes and Case Studies

Understanding the Tax Burden on Textiles Exported from Australia

Hainans Textile Industry Boosts Promotion with Price Incentives

Understanding the Super Symbols of Textiles:A Comprehensive Guide