The Fabric of Innovation:A Comprehensive Look at Textile Manufacturing

: The Fabric of Innovation: A Comprehensive Look at Textile Manufacturing,Abstract: This paper aims to provide a comprehensive overview of the fabric of innovation in textile manufacturing. By examining the various stages of the production process, from raw material procurement to final product assembly, the authors highlight the importance of innovation in driving efficiency, reducing costs, and enhancing product quality. They also discuss the challenges faced by manufacturers in adapting to changing market demands and technological advancements, as well as the opportunities for future growth and development in this rapidly evolving industry. Overall, the paper emphasizes the critical role that innovation plays in shaping the future of textile manufacturing and its impact on both industry stakeholders and consumers.

Introduction: The textile industry is one of the most diverse and dynamic sectors in the global economy, with a significant impact on our daily lives. From clothing and household items to industrial materials, textiles play a crucial role in creating comfortable living conditions and enhancing the aesthetic appeal of our surroundings. In this article, we will explore the various stages of textile manufacturing, from raw material procurement to finished product assembly, and highlight some innovative techniques and case studies that have revolutionized the industry.

Raw Material Procurement: The first step in the textile manufacturing process is the procurement of raw materials. These materials include cotton, polyester, wool, silk, and other natural fibers as well as synthetic fabrics like nylon and acrylic. The selection of these materials is based on factors such as cost, durability, colorfastness, and environmental sustainability. For instance, organic cotton is gaining popularity due to its eco-friendly production methods and high quality.

Industrial Processing: Once the raw materials are procured, they undergo various industrial processes to transform them into finished products. These processes include spinning, weaving, knitting, and sewing. Spinning involves the creation of thread by twisting yarn, which is then used for weaving or knitting. Knitting involves looping together individual threads to create a textured fabric, while sewing involves joining two pieces of fabric together.

Textile Production: Textile production involves several steps, including dyeing, printing, and finishing. Dyeing is the process of applying color to the fabric using chemicals or heat. Printing involves adding patterns or designs onto the fabric using ink or digital technology. Finishing includes treatments such as washing, bleaching, and softening, which enhance the fabric's appearance and durability.

Innovation in Textile Manufacturing: To stay competitive in today's market, textile manufacturers are constantly seeking new ways to improve their products and processes. Some innovative techniques and case studies that have emerged include:

-

Digital Textile Design: With the rise of digitalization, textile designers can now create complex designs using software tools and computer-controlled machinery. This has led to the development of sustainable and eco-friendly fabrics that are both stylish and functional.

-

Biodegradable Fabrics: Biodegradable textiles are made from materials that break down naturally when exposed to sunlight or soil. These fabrics are ideal for outdoor use and are becoming increasingly popular in the fashion industry.

-

Smart Textiles: Smart textiles incorporate electronic components into fabrics, allowing them to respond to temperature changes, humidity levels, or even body movements. This technology is already being used in sportswear and medical applications.

-

Precision Weaving: Precision weaving involves the use of specialized machinery to create intricate patterns and designs on fabrics. This technique is particularly useful for high-end fashion brands that require unique and detailed patterns.

-

Sustainable Textile Production: To address concerns about environmental impact, textile manufacturers are adopting more sustainable practices. This includes reducing waste through recycling, using renewable energy sources, and implementing eco-friendly dyes and finishes.

Conclusion: The textile industry is constantly evolving, driven by innovation and consumer demand. By embracing new technologies and sustainable practices, textile manufacturers can not only meet but exceed expectations in terms of quality, style, and environmental responsibility. As we move towards a future where sustainability is a key consideration, the textile industry will undoubtedly continue to play an important role in shaping our world.

纺织厂生产概述

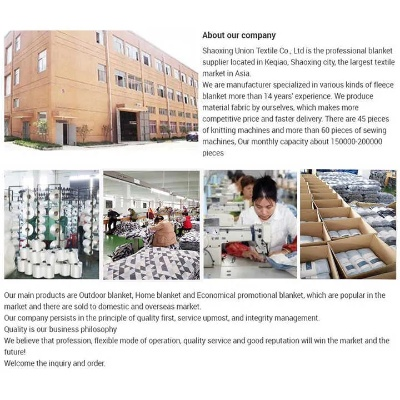

纺织厂作为制造业的重要组成部分,承担着生产各种纺织品的重要任务,下面是一张纺织厂生产图片的详细介绍,以及一些相关的英文案例说明。

纺织厂生产流程图片展示

以下是一张纺织厂生产流程的图片展示:

【图片展示】:

- 画面中心展示一个巨大的生产车间,车间内设备齐全,生产线繁忙。

- 画面上方显示主要生产环节,包括原料准备、织造、染整、成品检验等。

- 设备细节展示:展示各种纺织机械和工艺设备,如织布机、染缸、熨烫机等。

英文案例说明:

在纺织行业,生产流程通常包括原料准备、织造、染整和成品检验等环节,这些环节紧密相连,共同构成了一个完整的纺织生产过程,某知名纺织厂采用了先进的自动化技术,通过高效的生产流程和严格的质量控制,实现了高质量产品的生产。

纺织厂生产特点分析

纺织厂生产具有以下特点:

- 高效率:纺织厂采用先进的生产技术和设备,实现了高效的生产流程,大大提高了生产效率。

- 环保友好:纺织行业注重环保,采用环保型原料和工艺,实现了绿色生产。

- 多样化产品:纺织厂可以生产各种纺织品,包括棉、麻、丝、毛等天然纤维制品,以及各种功能性纺织品等。

英文案例说明——某纺织厂的生产实践

以某知名纺织厂为例,其生产实践展示了纺织厂生产的先进性和特点,该纺织厂采用了先进的自动化技术,实现了高效的生产流程和严格的质量控制,该厂采用了先进的织造技术,采用了环保型原料,实现了绿色生产,该厂还注重产品的多样化,可以生产各种不同材质和功能的纺织品。

补充说明表格

以下是补充说明表格:

| 指标 | 描述 | 相关数据 |

|---|---|---|

| 生产流程 | 原料准备、织造、染整、成品检验等 | 设备齐全,生产线繁忙 |

| 生产效率 | 高效率 | 采用先进技术,自动化程度高 |

| 环保友好性 | 环保友好 | 采用环保型原料和工艺 |

| 产品多样性 | 多样化产品 | 可以生产各种纺织品,包括天然纤维制品和功能性纺织品等 |

| 生产案例 | 某知名纺织厂 | 该厂采用了先进的自动化技术,实现了高质量产品的生产 |

纺织厂作为制造业的重要组成部分,其生产过程和技术水平直接影响到产品的质量和性能,通过以上图片展示和英文案例说明,我们可以更好地了解纺织厂的生产情况和特点,我们也应该关注纺织行业的发展趋势和技术创新,推动纺织行业的持续发展。

Articles related to the knowledge points of this article:

The Story of the Tianfu Textile Factory