Operational Challenges and Strategies at Runciu Runda Textile Factory

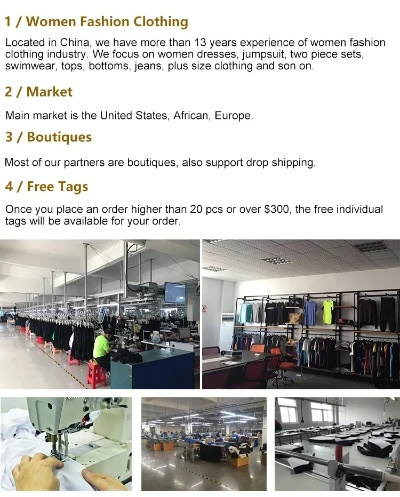

Runciu Runda Textile Factory, located in the heart of China's textile industry, faces numerous operational challenges that require strategic solutions. These include high labor costs, limited technological advancements, and a lack of market diversification. To address these issues, the factory has implemented several strategies, including improving production efficiency through automation, investing in research and development to develop new products, and expanding into new markets. Additionally, the factory has sought to enhance its brand image by adopting eco-friendly practices and promoting sustainable business practices. By implementing these strategies, Runciu Runda is positioned to overcome its operational challenges and achieve long-term success in the competitive textile industry.

Introduction: Running a textile factory is no small feat, especially in the competitive world of global markets. At Runciu Runda Textile Factory, located in Runciu, Runciu, Shanxi, China, the challenges faced by the management team are multifaceted. This article will explore some of the operational challenges faced by the factory, along with strategies employed to overcome them. We will also present an illustrative case study to demonstrate the effectiveness of these strategies.

Operational Challenges Faced by Runciu Runda Textile Factory:

-

Supply Chain Management: The supply chain is a critical component of any textile factory. At Runciu Runda Textile Factory, one of the main challenges is managing the complex supply chain effectively. The factory relies on suppliers from various regions, including North America, Europe, and Asia. Managing these relationships requires constant communication and coordination to ensure timely delivery and quality control.

-

Employee Satisfaction and Morale: Employee satisfaction and morale are crucial for the success of a textile factory. At Runciu Runda Textile Factory, there have been instances where employees felt undervalued or unappreciated. This has led to low morale and decreased productivity. To address this issue, the factory has implemented a variety of initiatives, such as regular training sessions, recognition programs, and open communication channels.

-

Product Quality Control: Product quality is a top priority for any textile factory. At Runciu Runda Textile Factory, there have been instances where products were not meeting customer expectations due to quality issues. To address this challenge, the factory has invested in advanced quality control equipment and trained staff to ensure that every product meets industry standards.

-

Environmental Sustainability: As the world becomes more aware of environmental concerns, sustainability has become a major focus for many businesses. At Runciu Runda Textile Factory, the factory has taken steps to reduce its environmental impact, such as using recycled materials and implementing energy-efficient machinery. However, there is still room for improvement, and the factory is committed to further enhancing its sustainability efforts.

Strategies Employed to Overcome Challenges:

-

Effective Supply Chain Management: To manage the complex supply chain effectively, the factory has implemented a comprehensive supply chain management system. This system includes regular supplier reviews, inventory management, and order fulfillment tracking. By leveraging technology, such as ERP systems and cloud-based software, the factory can better track its supply chain and respond quickly to changes in demand and supplier performance.

-

Employee Satisfaction and Morale: To improve employee satisfaction and morale, the factory has implemented several initiatives. These include regular training sessions, recognition programs, and open communication channels. Additionally, the factory has established a culture of continuous improvement and feedback, encouraging employees to share their ideas and suggestions for improving operations and customer satisfaction.

-

Product Quality Control: To ensure consistent product quality, the factory has invested in advanced quality control equipment and trained staff to handle quality inspections. Additionally, the factory has implemented strict quality control measures throughout the production process, including quality assurance checks before shipment and regular audits of supplier quality.

-

Environmental Sustainability: To promote environmental sustainability, the factory has implemented several initiatives. These include reducing waste through recycling and reusing materials, using energy-efficient machinery, and implementing greener production processes. Additionally, the factory has partnered with local organizations to support renewable energy projects and educate customers about sustainable practices.

Case Study: One example of the effectiveness of these strategies is the recent launch of a new line of eco-friendly textiles by Runciu Runda Textile Factory. In response to increasing consumer demand for sustainable products, the factory developed a line of clothing made from organic cotton and recycled polyester. The line was launched at a trade show in New York City and received positive feedback from both buyers and consumers. This success highlights the importance of investing in innovative products and marketing strategies that align with consumer preferences and environmental concerns.

Conclusion: Running a textile factory is a challenging but rewarding endeavor. At Runciu Runda Textile Factory, the management team has faced numerous operational challenges, but they have successfully implemented strategies to overcome these challenges. From effective supply chain management to employee satisfaction and morale enhancement, from product quality control to environmental sustainability, the factory has shown that it is possible to achieve success while prioritizing these key areas. With continued dedication and innovation, Runciu Runda Textile Factory can continue to thrive and provide high-quality products to customers around the world.

背景介绍

运城润达纺织品工厂作为当地的重要产业,以其先进的生产设备、精湛的工艺和丰富的产品种类,吸引了众多国内外客户的关注,该工厂不仅注重产品质量,更注重环保和可持续发展,致力于为客户提供高质量、环保、可持续的纺织品。

工厂概况

- 地理位置:位于运城市经济技术开发区,交通便利,地理位置优越。

- 生产设备:工厂拥有先进的生产设备,包括全自动织机、染整设备等,确保了产品的质量和效率。

- 产品种类:主要生产各类纺织品,包括棉布、丝绸、麻布等,产品种类丰富。

案例分析

- 先进技术:工厂采用先进的织造技术和染整工艺,确保了产品的质量和环保性能,工厂还注重技术创新,不断引进先进的生产设备和技术,提高生产效率和产品质量。

- 环保理念:工厂注重环保和可持续发展,采用环保材料和生产工艺,减少环境污染和资源浪费,工厂还积极推广绿色生产理念,提高员工环保意识。

工厂运营情况

- 生产流程:工厂的生产流程严格按照国家标准和客户需求进行,确保产品的质量和交货期,工厂还注重生产过程的节能减排,采用先进的节能技术和环保设备,降低生产成本和环境污染。

- 质量管理体系:工厂建立了完善的质量管理体系,从原材料采购到成品出厂都有严格的质量控制流程,工厂还注重员工培训和技能提升,提高员工的质量意识和技能水平。

- 客户服务:工厂注重客户服务,提供优质的产品和服务,工厂还积极响应客户需求,不断优化产品和服务,提高客户满意度。

英文案例说明

运城润达纺织品工厂的产品种类及主要生产设备

| 产品种类 | 主要生产设备 | 描述 |

|---|---|---|

| 棉布 | 全自动织机 | 采用先进的织造技术,生产各种规格的棉布 |

| 丝绸 | 染整设备 | 采用先进的染整工艺,生产高质量的丝绸面料 |

| 麻布 | 其他设备 | 根据客户需求定制生产其他类型的麻布 |

运城润达纺织品工厂的环保和可持续发展举措

| 环保和可持续发展举措 | 描述 |

|---|---|

| 先进技术:采用环保材料和生产工艺 | 确保产品的质量和环保性能 |

| 环保理念:注重环保和可持续发展 | 积极推广绿色生产理念,减少环境污染和资源浪费 |

| 生产流程:节能减排 | 采用先进的节能技术和环保设备,降低生产成本和环境污染 |

运城润达纺织品工厂以其先进的生产设备、精湛的工艺和丰富的产品种类,以及环保和可持续发展的理念,成为了当地的重要产业,该工厂注重产品质量和员工培训,积极响应客户需求,不断提高生产效率和产品质量,该工厂将继续致力于提高生产效率和产品质量,为国内外客户提供更高质量、环保、可持续的纺织品。

Articles related to the knowledge points of this article:

Exploring the World of Textiles:A Glossary of Different Fabric Materials

The Magic of Silver-Infused Textiles

The Enigmatic World of Industrial Fabrics and Their Variegated Spectrum

Table 1:Major International Textile Markets

Textiles:Understanding the World of Clothing and Interior Decorations