The Rise of Global Digital Printing in Textiles

Global Digital Printing in Textiles: A Brief Overview,In recent years, the digital printing industry has experienced significant growth in textile sectors. This trend is driven by advancements in technology and changing consumer preferences, making it increasingly popular for producing high-quality garments and accessories. The rise of global digital printing in textiles has been fueled by factors such as increased demand for sustainable materials, the need for faster production cycles, and the desire for more personalized and customized products. As a result, manufacturers are now turning to digital printing methods that allow them to produce intricate designs and vivid colors with greater precision and efficiency than traditional methods.

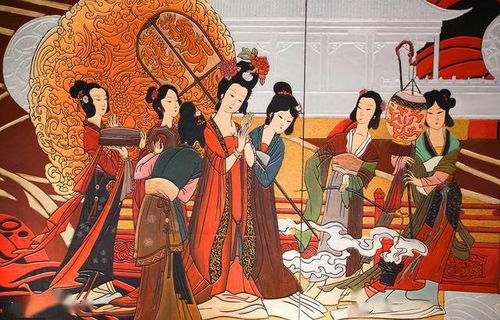

Introduction: The textile industry, with its vast array of fabrics, patterns, and colors, has always been a canvas for creativity. However, the traditional methods of printing, such as screen printing or embroidery, have limitations in terms of speed, cost-effectiveness, and scalability. Enter the world of digital printing, which has revolutionized the way textiles are produced. In this article, we will explore the global landscape of digital printing in textiles, including its advantages, challenges, and case studies.

Advantages of Digital Printing in Textiles:

- Speed and Efficiency: Digital printing can produce high-quality prints in seconds, compared to days or weeks for traditional methods. This makes it ideal for mass production and fast-moving fashion trends.

- Cost-Effectiveness: Digital printing is more cost-effective than traditional methods, especially when considering the initial investment in equipment and software. It also reduces waste by producing fewer printed pieces per sheet.

- Scalability: Digital printing is highly scalable, allowing manufacturers to produce large quantities of textiles without compromising quality.

- Customization: With digital printing, designers and manufacturers can create unique and personalized products that cannot be achieved through traditional methods.

- Environmental Benefits: Digital printing uses less water and energy than traditional methods, making it more sustainable.

Challenges of Digital Printing in Textiles:

- Technical Skills: Digital printing requires specialized knowledge and training for operators, which can be costly and time-consuming.

- Quality Control: As with any manufacturing process, there is a risk of errors in digital printing, which can affect the final product's appearance and functionality.

- Material Selection: The choice of materials for digital printing can impact the quality of the final product, as certain fabrics may not be suitable for certain types of inks or printing techniques.

- Regulations and Standards: Digital printing requires compliance with specific regulations and standards, which can vary depending on the country or region.

Case Studies:

- Nike: Nike has been at the forefront of digital printing technology in sportswear. The company uses a combination of screen printing and digital printing techniques to create high-quality graphics and logos on their apparel. This not only enhances the aesthetic appeal of their products but also improves efficiency and reduces costs.

- Zara: Zara is another leading retailer that has embraced digital printing technology. The company uses this technique to create trendy and stylish designs for their clothing line. By using digital printing, Zara is able to quickly respond to changing fashion trends and meet customer demand.

- H&M: H&M has implemented a digital printing system in their home textile division, which produces a range of home decor items, such as curtains, tablecloths, and wallpapers. This system allows H&M to produce high-quality prints in a short amount of time while reducing waste and improving efficiency.

Conclusion: Digital printing in textiles has emerged as a powerful tool for modern manufacturers, offering both cost savings and increased flexibility. While there are challenges to overcome, including technical skills and regulatory compliance, the benefits of this technology make it an essential component of the industry's future. As the demand for sustainable and eco-friendly products continues to grow, digital printing will play a crucial role in meeting those demands.

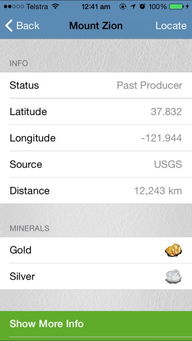

随着科技的飞速发展,纺织品数码喷墨印花技术已成为全球纺织行业的新趋势,数码喷墨印花以其高效率、高精度、环保等优点,正在逐渐改变传统纺织生产的模式,本篇文章将详细介绍全球纺织品数码喷墨印花的发展现状、案例分析以及未来趋势。

全球纺织品数码喷墨印花的发展现状

技术进步

近年来,纺织品数码喷墨印花技术取得了显著的技术进步,喷墨印花设备采用了先进的数字控制技术,能够精确控制喷墨量、喷墨色彩和图案,大大提高了印花的质量和效率,数字化技术的应用也使得纺织品的设计和制造更加灵活和个性化。

应用领域扩展

纺织品数码喷墨印花的应用领域正在不断扩大,从传统的服装面料到家居用品、户外用品等各个领域,数码喷墨印花技术都得到了广泛应用,随着环保意识的提高,越来越多的企业开始关注绿色纺织品的生产,数码喷墨印花技术也成为了绿色纺织生产的重要手段。

案例分析

以某知名纺织品品牌为例,介绍其数码喷墨印花技术的应用和成果,该品牌采用了先进的数码喷墨印花设备和技术,成功实现了纺织品的高效、环保、个性化的生产。

生产流程

该品牌在生产过程中采用了数码喷墨印花技术,实现了从原材料到成品的全过程数字化管理,通过数字化设计软件进行图案设计,然后通过喷墨打印机将图案打印在纺织品上,在生产过程中,设备能够实时监测印花质量,确保产品质量。

成果展示

该品牌生产的纺织品具有高精度、高效率、环保等特点,其图案设计具有很高的艺术性和创新性,能够满足不同消费者的需求,该品牌生产的纺织品也具有很好的透气性和舒适性,受到了广大消费者的喜爱,该品牌还注重绿色环保,采用了环保材料和生产工艺,实现了绿色生产。

未来趋势

技术创新

纺织品数码喷墨印花技术将继续保持技术创新的发展趋势,随着数字控制技术的不断进步,数码喷墨印花设备的性能和效率将进一步提高,数字化和智能化技术的应用也将进一步拓展数码喷墨印花技术的应用领域。

应用领域拓展

纺织品数码喷墨印花的应用领域还将进一步拓展,随着人们对纺织品品质和环保要求的提高,数码喷墨印花技术将在更多领域得到应用,如家居用品、户外用品、儿童用品等,随着绿色纺织品的生产需求增加,数码喷墨印花技术也将成为绿色纺织生产的重要手段。

纺织品数码喷墨印花技术的发展为全球纺织行业带来了新的机遇和挑战,在未来的发展中,我们需要继续关注技术创新和应用领域拓展,推动纺织品数码喷墨印花技术的进一步发展,我们也需要注意环保和可持续发展的问题,实现纺织品数码喷墨印花技术的绿色生产。

Articles related to the knowledge points of this article:

Global Trade in Fashion Textiles:An Overview of Key Markets and Industries

The Scope of Textile Design in a Professional Focus

A Detailed Guide to Shopping at Yuers Textile Live Room