Textile Waterproofing Inspection Standards for Quality Control

: Textile Waterproofing Inspection Standards for Quality Control,This paper presents the textile waterproofing inspection standards for quality control. The standards include the following aspects: (1) waterproofing performance, (2) waterproofing materials, (3) waterproofing process, and (4) waterproofing quality assurance. These standards are designed to ensure that the waterproofing work of textile products meets the requirements of the relevant national and international standards. In addition, the standards also provide specific technical content and implementation methods for each aspect of waterproofing inspection, which can help enterprises improve the quality control level of their waterproofing work.

Introduction: Textile products are a fundamental component of our daily lives, and their quality is crucial for ensuring that they meet the demands of both consumers and manufacturers. One of the critical parameters that determine the performance of a textile product is its water resistance capability. This is where the topic of textural water absorption (water vapor transmission rate) comes into play. In this article, we will explore the various methods used to assess the water absorption characteristics of textiles, as well as provide insights on the standards governing these tests. Additionally, we will illustrate how these standards can help in identifying potential flaws in textile products, thereby ensuring their long-term durability and functionality.

Textural Water Absorption Testing Methods: The process of measuring the water absorption capacity in textiles involves subjecting the material to a controlled environment that simulates the conditions under which it would be exposed in practical applications. Here are some common methods used for assessing the water absorption of textiles:

Damping Balance Method: This method measures the weight loss of a fabric sample when subjected to a known quantity of water for a given period. The results are expressed as the percentage of weight loss relative to the initial weight.

Sorption Test: This test involves placing samples of the textile in a container containing distilled water and monitoring the changes in weight over time. The weight gain or loss is then calculated to determine the amount of water absorbed.

Water Vapor Transmission Rate Test: This test uses high-quality infrared sensors to measure the rate at which water vapor passes through the textile material. It is an accurate and precise technique that provides a more comprehensive assessment of the material's moisture management capabilities.

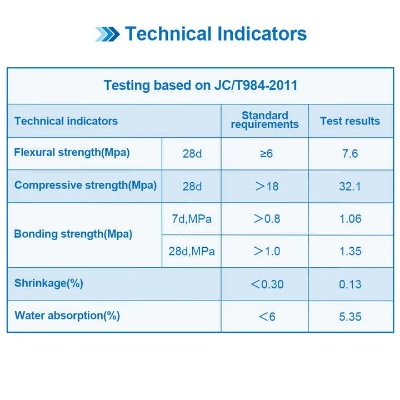

Standards and Regulations: Several organizations worldwide have established guidelines and standards for the testing of textiles, including water vapor transmission rates and water absorption capacities. Some of these standards include:

ISO 139:2005 "Test Method for Water Absorption by Textiles" ASTM D576:2008 "Method for Determining Water Absorption Capacity of Textile Materials" EN 13434:2009 "Test Method for Water Vapor Transmission Rate of Textile Materials" NF U 8270:2011 "Standard Norme de la Visibilité et de la Permettance de Traverser des Espaces en Fabrications"

In addition to these international standards, many countries have also developed local regulations that specify the minimum requirements for water absorption and water vapor transmission rates in textiles. These regulations vary depending on the intended use of the textile products and the level of protection required from moisture.

Case Study: Consider a scenario where a manufacturer is producing clothing made from polyester fabric. The company has decided to comply with international standards such as ISO 139:2005 and ASTM D576:2008 to ensure that its clothing is resistant to moisture and does not lose its shape after washing. To achieve this, the manufacturer conducts regular testing of its polyester garments using the ISO standard. The results show that the fabric meets the specified water absorption limits, which means that it can handle sweat and other liquids without losing its integrity or color. This information is then shared with retailers and customers, helping them trust the brand and knowing that they are buying high-quality, durable apparel.

Conclusion: Textile waterproofing inspection standards serve as a reliable guideline for assessing the water resistance properties of textile products. By following these standards and regulations, manufacturers can ensure that their products meet customer expectations and industry requirements. Furthermore, understanding these standards can help textile professionals identify areas where improvements can be made to enhance the overall performance and durability of their products. As technology continues to advance, it is important for textile manufacturers to stay updated on the latest standards and regulations to remain competitive in the global marketplace.

随着人们对生活品质的要求不断提高,纺织品作为日常生活中的必需品,其质量越来越受到关注,为了确保纺织品在使用过程中具备优良的防水性能,确保消费者的使用体验,制定并执行严格的纺织品渗水性检测标准显得尤为重要,本文将详细介绍纺织品渗水性检测的标准内容,并通过案例分析进一步说明其实际应用。

纺织品渗水性检测标准概述

检测标准定义

纺织品渗水性检测标准主要涉及纺织品在特定环境条件下,如潮湿、雨水等,能否有效防止水分渗透的性能,该标准规定了检测方法、测试样品、测试环境等要素,以确保检测结果的准确性和可靠性。

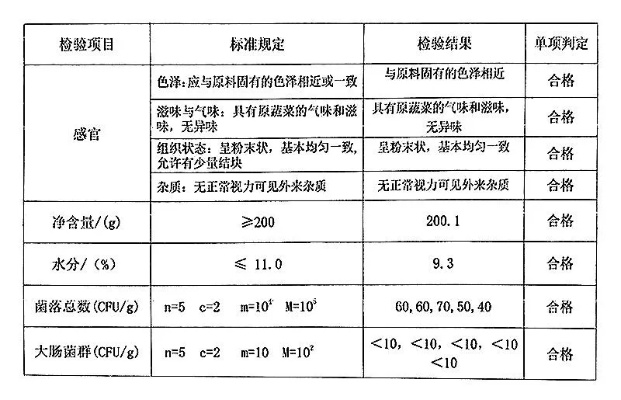

主要检测指标

(1)吸水性:纺织品在特定湿度条件下吸收水分的能力。 (2)防水性能等级:根据吸水性测试结果,划分出不同防水性能等级的标准。 (3)测试方法:采用国家标准规定的测试方法,包括吸水性测试、防水性能试验等。

纺织品渗水性检测标准案例分析

某品牌纺织品渗水性检测标准执行情况

某品牌在纺织品生产过程中,非常重视产品质量和消费者体验,为了确保其产品具备优良的防水性能,该品牌严格按照纺织品渗水性检测标准进行生产。

- 检测方法:采用国家标准规定的吸水性测试和防水性能试验方法。

- 测试样品:选取该品牌的多款不同材质的纺织品样品。

- 测试环境:模拟潮湿、雨水等特定环境条件。

经过严格检测,该品牌的多款纺织品样品均符合渗水性检测标准,防水性能等级较高,消费者在使用该品牌纺织品时,可以放心享受其优良的防水性能。

渗水性检测标准在实际应用中的重要性

在实际应用中,纺织品渗水性检测标准的实施对于保障消费者权益、提高产品质量具有重要意义,具体表现在以下几个方面:

(1)保障消费者权益:通过严格把控纺织品渗水性检测标准,可以确保消费者购买到具备优良防水性能的纺织品,提高消费者的使用体验。 (2)提高产品质量:通过严格执行渗水性检测标准,可以确保纺织品在生产过程中符合质量要求,提高产品的整体质量。 (3)促进行业健康发展:纺织品渗水性检测标准的实施对于促进纺织品的行业健康发展具有积极意义,有助于提升整个行业的生产水平和技术水平。

纺织品渗水性检测标准补充说明

检测方法选择与实施

在纺织品渗水性检测过程中,应选择科学、规范、可靠的方法进行测试,具体方法包括吸水性测试和防水性能试验等,在实施过程中,应严格按照国家标准和相关法规进行操作,确保测试结果的准确性和可靠性。

影响因素分析

影响纺织品渗水性检测的因素主要包括材料成分、生产工艺、环境条件等,在制定和执行纺织品渗水性检测标准时,应充分考虑这些因素,确保测试结果的客观性和准确性。

总结与展望

纺织品渗水性检测标准的制定和执行对于保障消费者权益、提高产品质量具有重要意义,在实际应用中,应严格按照国家标准和相关法规进行操作,确保测试结果的准确性和可靠性,应不断加强技术创新和人才培养,提高纺织品的生产水平和整体质量,随着科技的不断进步和消费者需求的不断变化,纺织品渗水性检测标准将不断发展和完善,为纺织品的生产和质量提供更加可靠的保障。

Articles related to the knowledge points of this article:

Immersing Yourself in Realistic and High-Definition Mobile Textile Images

Navigating the Global Trade Landscape with Nanjing Hanxiaochen Textiles

Dream Somance Textile Factory:A Journey of Innovation and Sustainability

The Dynamics and Innovation of Zunyi Textile Brand Womens Fashion