Understanding the SGS Textile Inspection Process

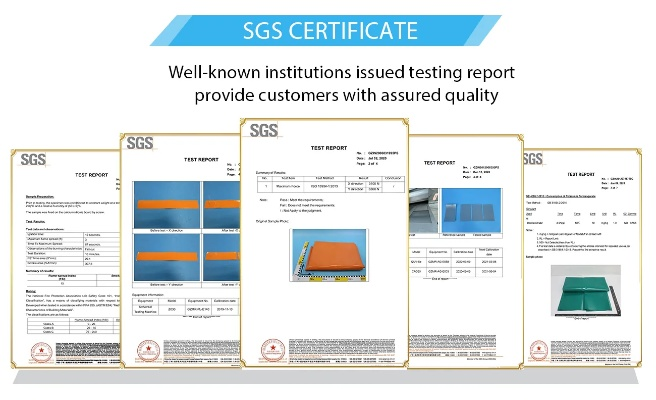

SGS Textile Inspection Process: An Overview,The SGS (Standards Testing Group) is a globally recognized testing and certification company that specializes in textile inspection. Their process involves several key steps to ensure the quality and safety of textile products.,Firstly, the product is inspected for any defects or flaws such as loose threads, holes, or uneven stitching. This helps identify any potential issues with the product before it reaches the consumer.,Secondly, the product undergoes a series of tests to evaluate its performance under various conditions. These tests may include strength testing, tear testing, and colorfastness testing.,Thirdly, the results of the tests are analyzed to determine if the product meets the required standards. If the product passes all the tests, it is certified as meeting the SGS standards.,Lastly, the certificate of compliance is issued to the manufacturer, which ensures that the product can be sold in international markets.,Overall, the SGS Textile Inspection Process is a rigorous and thorough method of ensuring the quality and safety of textile products, helping to protect consumers and promote fair trade.

Introduction: In today's globalized world, textile products are in high demand worldwide. To ensure that these products meet international standards and consumer expectations, SGS (SGS Group), a global testing and inspection company, offers comprehensive textile product inspection services. In this article, we will discuss the key steps involved in the SGS textile inspection process, including sample collection, testing, and reporting. We will also provide an example of how SGS has helped a textile manufacturer comply with international standards.

Sample Collection: Before any testing can begin, it is essential to collect a representative sample of the textile product. The sample should be carefully selected to represent the entire batch of products being tested. Here is an example of how SGS collects a sample:

- Label the sample container clearly with the test code and the date of collection.

- Ensure that the sample is properly packaged and protected from external factors that may affect the testing results.

- Transport the sample to the SGS laboratory for testing.

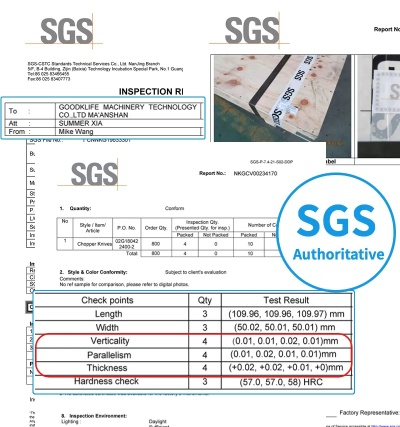

Testing: Once the sample is received at SGS, it undergoes various tests to evaluate its quality, composition, and compliance with international standards. These tests include:

- Composition Testing: This test checks the percentage of each type of fiber in the fabric. It ensures that the fabric meets the required composition requirements.

- Stability Testing: This test measures the stability of the fabric over time. It helps identify any issues with the fabric's durability or resistance to wear and tear.

- Finishing Testing: This test evaluates the quality of the fabric's finishing processes, such as dyeing, printing, and coating. It ensures that the finished product meets the desired aesthetic and functional requirements.

- Environmental Testing: This test assesses the fabric's impact on the environment, including its water and energy consumption, and its contribution to pollution.

- Safety Testing: This test ensures that the fabric does not pose any health risks to consumers. It evaluates the fabric's toxicity levels and other safety concerns.

Reporting: After completing all the tests, SGS provides a detailed report on the results of the inspection. This report includes information on the fabric's composition, stability, finish, environmental impact, and safety. Based on the findings, SGS recommends any necessary corrective actions to help the textile manufacturer improve their products.

Example: Let's take a look at an example of how SGS has helped a textile manufacturer comply with international standards. XYZ Textiles, a leading producer of high-quality cotton fabrics, faced challenges in meeting strict European Union (EU) regulations regarding pesticide residues in their products. XYZ Textiles approached SGS for assistance in conducting a comprehensive pesticide residue testing program.

Using advanced analytical techniques, SGS identified the presence of specific pesticides in some of their fabric samples. Upon receiving this information, XYZ Textiles promptly implemented changes to their production process, reducing the use of certain pesticides and implementing stricter controls to ensure that no harmful substances were present in their products.

Following the implementation of these changes, XYZ Textiles successfully passed all EU regulations related to pesticide residues. As a result, they gained a significant competitive advantage in the European market and expanded their customer base.

Conclusion: The SGS textile inspection process involves careful sample collection, thorough testing, and accurate reporting. By providing reliable and comprehensive testing services, SGS helps textile manufacturers comply with international standards and meet consumer expectations. In this article, we have provided an overview of the key steps involved in the SGS inspection process and shared an example of how SGS has helped a textile manufacturer comply with international standards.

大家好,今天我们将围绕SGS纺织品商检的主题,探讨其在纺织品检验过程中的重要性和流程,商检是确保纺织品质量的重要环节,对于保障消费者权益和促进国际贸易具有重要意义。

SGS纺织品商检概述

SGS是全球知名的检验、鉴定和测试服务机构,其纺织品商检服务涵盖了从原料采购到成品出货的整个过程,SGS通过严格的质量控制体系,确保纺织品符合相关标准和国际质量安全体系。

商检流程

- 样品准备:在商检过程中,首先需要准备样品,样品应包括原材料、面料、辅料等,确保其符合商检要求。

- 检验检测:SGS的检验检测团队会对样品进行全面的质量检测,包括外观质量、尺寸规格、性能指标等。

- 数据分析:检测结果需要进行数据分析,以确定纺织品的质量状况,数据分析可以采用各种统计方法,如回归分析、方差分析等。

- 报告出具:根据检测结果,SGS会出具详细的商检报告,包括检验结果、质量评价、问题点等。

案例说明

以某纺织品商检为例,说明SGS在纺织品商检过程中的具体操作和效果。

- 案例背景:某纺织品公司采购了一批原材料,准备生产出口商品,为了确保产品质量和符合国际标准,该公司选择了SGS进行纺织品商检。

- 商检过程:SGS的检验检测团队对原材料进行了全面的质量检测,包括纤维含量、织物结构、尺寸规格等,还对生产过程中的质量控制进行了检查。

- 检测结果:经过检测,发现原材料纤维含量符合要求,织物结构稳定,尺寸规格符合标准,还发现了一些潜在的问题点,如某些辅料的质量不稳定等。

- 商检效果:通过商检报告,该纺织品公司了解了产品的质量状况和存在的问题点,为后续的生产和质量控制提供了依据,也提高了该公司的产品质量意识和国际竞争力。

SGS纺织品商检是确保纺织品质量的重要环节,其流程和效果对于保障消费者权益和促进国际贸易具有重要意义,在商检过程中,SGS会严格遵守相关标准和国际质量安全体系,确保样品的质量和检测结果的准确性,SGS还会提供详细的商检报告,为纺织品公司提供有效的质量控制和改进方案。

Articles related to the knowledge points of this article:

Embracing the Global Scene:The Story of Shaoxing Qiaoyi Textiles

Easty Textiles:The Global Fabric of Modern Living