Understanding the Key Ingredients of Textile Printing Color Recipes

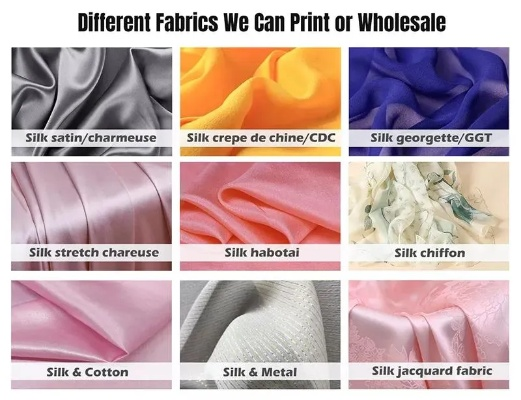

Textile printing color recipes are complex systems that involve a variety of ingredients, including dyes, pigments, and additives. The key ingredients in these recipes are responsible for determining the final color and hue of the printed textile.,Dyes are the primary colorants used in textile printing, and they can be either natural or synthetic. Natural dyes are derived from plants or animals, while synthetic dyes are chemically synthesized. Both types of dyes have unique properties that affect their color intensity and stability.,Pigments are also essential in textile printing color recipes. They are used to enhance the color of the dyes and provide additional hues and shades. Pigments can be organic or inorganic, and their selection depends on the desired effect and durability of the printed textile.,Additives such as fixatives, fixation agents, and dispersants are also crucial in creating vibrant and long-lasting textile prints. Fixatives help to stabilize the dyes and prevent fading, while fixation agents ensure that the colors remain consistent over time. Dispersants help to evenly distribute the pigments and dyes throughout the fabric, resulting in a uniform print.,In conclusion, understanding the key ingredients in textile printing color recipes is essential for creating vibrant and high-quality prints. By carefully selecting the right dyes, pigments, and additives, designers can achieve their desired aesthetic and functional goals.

Introduction Textile printing is a process where designs are applied to fabrics using ink, dyes, and other materials. The color of the printed design is determined by the combination of these elements, which requires precise control of their ratios. In this guide, we'll explore the key ingredients of textile printing color recipes and how they work together to achieve vibrant, consistent results. Let's dive into the details!

-

Color Base:

- Type: A base layer that provides the foundation for the printed design. It should be compatible with the inks used and have good adhesion to the fabric.

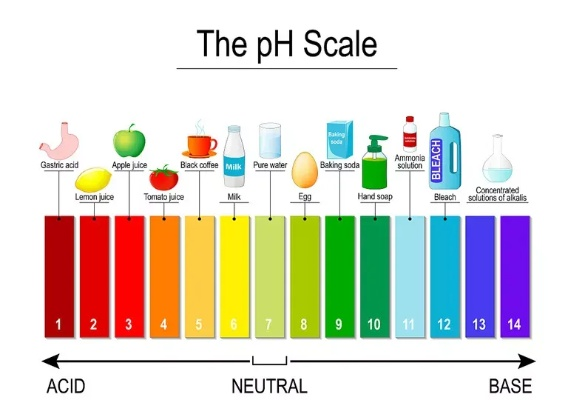

- Example: Cotton or polyester can be used as color bases due to their natural fiber properties. For example, if you're using an acid dye, cotton would be a suitable base because it has natural cellulose structures that can hold the dye molecules.

-

Ink/Dye:

- Type: The actual colorant used in the printing process.

- Example: Acid dyes like Direct Red 80 are commonly used in digital printing. These dyes penetrate the fabric fibers and create a permanent color.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Transfer Method:

- Type: How the image is transferred from the printing plate to the fabric.

- Example: Digital printing uses a heat transfer method, where the image is melted onto the fabric using a hot iron.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate. This plate contains the image and is then coated with a layer of photosensitive material.

-

Paper Preparation:

- Type: The paper used for the printing plate, which holds the image and is transferred onto the fabric.

- Example: If you're printing on a digital press, you'd use a laser printer to make your printing plate

在纺织品印花制作过程中,调色配方比例的精准控制是确保印花效果美观、色彩丰富的重要环节,本篇文章将详细介绍纺织品印花调色配方比例的相关知识,并结合实际案例进行分析。

纺织品印花调色配方比例概述

颜料种类与比例

纺织品印花调色通常使用各种颜料,如染料、印花油墨等,不同颜料的种类和颜色深浅决定了调色配方中的颜料比例,鲜艳的红色可以使用较多的红色染料,而淡雅的蓝色则可以使用较少的蓝色染料。

调色配方比例示例

以下是一个纺织品印花调色配方比例的示例:

(表格)

| 颜料种类 | 红色染料 | 黄色染料 | 蓝色染料 | 其他辅助颜料 | 配方比例示例(%) |

|---|---|---|---|---|---|

| 鲜艳红色 | X% | Y% | Z% | 其他辅助颜料(如珠光粉、光泽剂等) | 50:30:20 |

在这个示例中,红色染料占配方总量的50%,黄色染料占30%,蓝色染料占20%,其他辅助颜料根据印花需求适量添加。

实际案例分析

纺织品印花调色成功案例

某品牌纺织品印花采用特定调色配方,成功制作出色彩鲜艳、图案丰富的印花效果,具体调色配方如下:

(具体案例)

- 颜料种类:主要使用红色染料和印花油墨。

- 颜料比例:红色染料占配方总量的70%,印花油墨适量添加。

- 结果展示:印花图案鲜艳饱满,色彩层次分明,深受消费者喜爱。

纺织品印花调色失败原因分析

虽然调色配方比例正确,但在实际操作中仍可能出现调色失败的情况,颜料种类选择不当、用量不准确、混合不均匀等都会影响印花效果,在实际操作中,需要密切关注印花效果,及时调整调色配方比例。

建议与总结

建议

(1)根据印花需求选择合适的颜料种类和颜色深浅。 (2)合理搭配颜料比例,确保印花效果美观、色彩丰富。 (3)注意颜料的质量和纯度,避免使用劣质颜料影响印花效果。 (4)在实际操作中,密切关注印花效果,及时调整调色配方比例。

纺织品印花调色配方比例是确保印花效果美观、色彩丰富的重要环节,在实际操作中,需要根据印花需求选择合适的颜料种类和颜色深浅,合理搭配颜料比例,并注意颜料的质量和纯度,在实际操作中还需要密切关注印花效果,及时调整调色配方比例,以达到最佳的印花效果。

Articles related to the knowledge points of this article:

Exploring the Art of Romance in Textiles

Exploring the Rich Tapestry of Quality Home Textiles from Qingdao Jinshang