The Art of Polishing and Finishing Textiles:A Comprehensive Guide

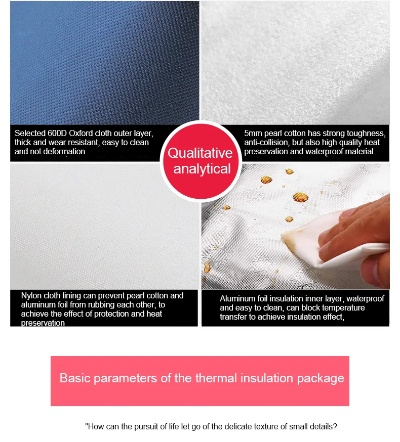

: "The Art of Polishing and Finishing Textiles: A Comprehensive Guide",This comprehensive guide delves into the art of polishing and finishing textiles, providing readers with a thorough understanding of the various techniques and tools used in this process. From basic cleaning and pretreatment to advanced finishing techniques such as burnishing, glazing, and coating, this guide covers every aspect of textile finishing.,The first section focuses on the importance of proper cleaning and pretreatment of textiles, highlighting the benefits of using appropriate solvents and chemicals to remove dirt, stains, and other contaminants. The guide also discusses the role of heat treatment in improving the quality and durability of finished textiles.,The second section explores the different types of finishing techniques available, including chemical finishes, mechanical finishes, and thermal treatments. Each technique is explained in detail, along with its advantages and limitations. Additionally, the guide provides tips for selecting the right type of finish for specific applications, such as garments or upholstery.,The third section covers the equipment and tools required for textile finishing, including brushes, rollers, and spray guns. The guide also provides information on how to maintain these tools to ensure consistent results and minimize downtime.,Finally, the guide concludes with a discussion of the environmental impact of textile finishing, emphasizing the importance of using sustainable materials and practices. Overall, this comprehensive guide provides a valuable resource for anyone interested in learning more about the art of polishing and finishing textiles.

Introduction: The finishing process is an essential part of the textile industry, as it not only enhances the appearance of the fabric but also improves its durability and comfort. Among the various finishing techniques, one of the most popular methods is the application of wax to textiles. This article will provide a detailed guide on how to apply wax to textiles using different methods, including dipping, brushing, and spraying. We will also discuss the benefits of applying wax to textiles and provide some tips for achieving a professional finish.

Dip Dipping Method: Dipping method involves submerging the textile in a solution containing wax and then draining off the excess wax. This method is suitable for small-scale production or when working with delicate fabrics that cannot withstand high heat. Here's a table outlining the steps for dipping method:

| Step | Description |

|---|---|

| 1 | Place the textile into a container filled with water and wax solution. |

| 2 | Submerge the textile completely in the solution. |

| 3 | Let the textile soak for the desired amount of time (usually around 10-15 seconds). |

| 4 | Remove the textile from the solution and drain any excess wax. |

| 5 | Rinse the textile thoroughly under running water to remove any remaining wax. |

| 6 | Dry the textile using a clean towel or air drying. |

Benefits of Dip Dipping Method:

- Easy to use and suitable for small-scale production.

- Can be used on a wide range of textiles, including cotton, silk, and wool.

- Results in a uniform and even coat of wax.

Tips for Successful Dip Dipping:

- Use a non-toxic wax solution that is safe for human skin and does not contain any irritants.

- Ensure that the textile is completely submerged in the solution before removing it to avoid streaks.

- Rinse the textile thoroughly to remove any residual wax.

Brushing Method: Brushing involves manually applying wax to the surface of the textile using a soft bristled brush. This method is suitable for larger-scale production and can be used on both natural and synthetic fibers. Here's a table outlining the steps for brushing method:

| Step | Description |

|---|---|

| 1 | Place the textile on a flat surface. |

| 2 | Apply a thin layer of wax using a soft bristled brush. |

| 3 | Work from the center outwards, covering the entire surface of the textile. |

| 4 | Allow the wax to dry completely before moving onto the next area. |

Benefits of Brushing Method:

- Can achieve a more uniform and even coat of wax compared to dipping method.

- Can be used on a wider range of textiles, including those with intricate designs or patterns.

- Results in a smoother and more polished finish.

Tips for Successful Brushing:

- Use a soft bristled brush to avoid damaging the textile's fibers.

- Start from the center and work towards the edges to prevent wax buildup on the sides.

- Be gentle while applying and removing the brush from the textile to avoid damaging the surface.

Spraying Method: Spraying involves applying wax directly to the surface of the textile using a spray bottle or applicator. This method is suitable for large-scale production and can be used on both natural and synthetic fibers. Here's a table outlining the steps for spraying method:

| Step | Description |

|---|---|

| 1 | Place the textile on a flat surface. |

| 2 | Pour a small amount of wax solution into a spray bottle or applicator. |

| 3 | Hold the applicator about 12 inches away from the textile surface. |

| 4 | Spray the wax evenly across the entire surface of the textile. |

| 5 | Allow the wax to dry completely before moving onto the next area. |

Benefits of Spraying Method:

- Can achieve a more uniform and even coat of wax compared to brushing method.

- Can be used on a wider range of textiles, including those with intricate designs or patterns.

- Results in a smoother and more polished finish.

Tips for Successful Spraying:

- Use a fine mist spray nozzle to avoid excessive dripping of wax.

- Hold the applicator at a consistent distance from the textile surface to ensure even coverage.

- Be careful not to overspray the textile, as this can cause damage to the surface.

Case Study: In the fashion industry, textile finishing plays a crucial role in creating a luxurious and appealing look for garments. One company that specializes in applying wax to textiles is Textile Wax Ltd. They offer a variety of wax solutions that are designed specifically for different types of fabrics and colors. For example, their Natural Linen Wax is perfect for enhancing the natural texture of linen fabrics, while their Colorfast Cotton Wax is ideal for preserving the vibrant colors of cotton garments. Textile Wax Ltd. has been in business for over 20 years and has gained a reputation for providing top-quality wax products that meet the needs of their customers.

Conclusion: Applying wax to textiles is an essential step in the finishing process that not only enhances the aesthetic appeal of the fabric but also improves its durability and comfort. Whether you choose to use dipping, brushing, or spraying methods, there are several options available to suit your specific needs and preferences. By following these guidelines and tips, you can achieve a professional finish that will leave your customers satisfied and impressed. So why wait? Start polishing your textiles today and see the difference for yourself!

针纺织品上蜡概述

针纺织品上蜡是一种常见的工艺手段,主要用于提升织物的光泽度和手感,本文将详细介绍针纺织品上蜡的方法和注意事项。

上蜡前的准备工作

- 选择合适的蜡料:根据织物的材质和需求,选择适合的蜡料,常见的蜡料包括天然蜡、合成蜡等。

- 准备工具:准备必要的工具,如刷子、手套、容器等。

- 检查织物:确保织物表面干净、无杂质,以便后续上蜡效果更佳。

上蜡方法

- 涂抹蜡料:使用刷子或手掌均匀涂抹蜡料在织物表面,注意涂抹时要轻柔,避免过多或过少。

- 加热处理:对于某些需要提高光泽度的织物,可以在涂抹蜡料后进行加热处理,如使用电熨斗或蒸汽机进行短暂熨烫。

- 冷却定型:蜡料干燥后,用适当的工具将织物定型,使其达到理想的外观。

案例说明

以下是一个具体的英文案例,以帮助更好地理解针纺织品上蜡的方法和注意事项:

天然蜡上蜡

- 选择合适的天然蜡:根据织物的材质和需求,选择适合的天然蜡,对于棉质衣物,可以选择天然蜂蜡或核桃油蜡。

- 准备工作:准备好刷子、手套、容器等工具,并确保织物表面干净。

- 上蜡步骤:用刷子均匀涂抹天然蜡在织物表面;使用电熨斗或蒸汽机进行短暂熨烫,使蜡料更好地渗透到织物中;用毛巾轻轻擦拭,去除多余蜡料,使织物达到理想的外观。

注意事项

- 选择合适的蜡料:务必选择适合织物的蜡料,避免使用不适合的蜡料导致织物变色或损坏。

- 上蜡前检查织物:确保织物表面干净、无杂质,以免影响上蜡效果。

- 上蜡时轻柔操作:避免过多或过少的蜡料涂抹,以免影响织物的外观和质量。

- 注意温度控制:在加热处理时,要注意温度的控制,避免过高或过低导致织物变形或损坏。

- 注意事项:在操作过程中要注意安全,避免接触皮肤或眼睛,要遵循正确的操作流程和注意事项,以确保上蜡效果和质量。

针纺织品上蜡是一种常见的工艺手段,可以提高织物的光泽度和手感,本文介绍了针纺织品上蜡的方法和注意事项,包括选择合适的蜡料、准备工作、上蜡步骤和注意事项等,在实际操作中,要遵循正确的操作流程和注意事项,以确保上蜡效果和质量,要注意安全,避免接触皮肤或眼睛,希望本文能够帮助大家更好地了解针纺织品上蜡的方法和注意事项。

Articles related to the knowledge points of this article:

Custom Textile Dryers for Enhanced Performance and Cost-Effectiveness

The Story of Shanghai Textile Companys First Wholesale Department