Textile Batching and Processing:A Comprehensive Guide

This comprehensive guide to textile batching and processing offers a detailed overview of the various techniques, equipment, and processes used in the industry. From pre-treatment to post-finishing, this guide covers everything needed to ensure that textiles are produced efficiently and effectively.,The first section of the guide covers the basic principles of textile processing, including the importance of quality control and environmental considerations. It also provides an overview of the different types of textile materials, such as cotton, polyester, and rayon, and their properties and uses.,The second section focuses on the various stages of textile processing, from dyeing and printing to finishing and packaging. Each stage is carefully explained, with diagrams and illustrations to help explain complex processes.,Finally, the guide concludes with a discussion of the latest developments and trends in textile processing, including new materials, technologies, and market trends.,Overall, this guide is an essential resource for anyone working in the textile industry, providing a comprehensive understanding of the process and equipment needed to produce high-quality textiles.

Introduction: In the textile industry, batching and processing are crucial steps that ensure the quality and consistency of final products. This guide will provide an overview of the different techniques used in textile manufacturing, including the application of modern machinery and processes. We'll also discuss the importance of quality control and the benefits of using advanced technology in this field.

Textile Batching Process:

-

Pre-treatment: Before starting the batching process, it's essential to clean and pre-treat the raw materials. This step involves removing any foreign particles, oils, or waxes that could interfere with subsequent processing.

-

Dyeing: The next step is dyeing, where the color is applied to the fabric. This can be done manually or by using a machine. The choice of dye depends on the desired shade and finish.

-

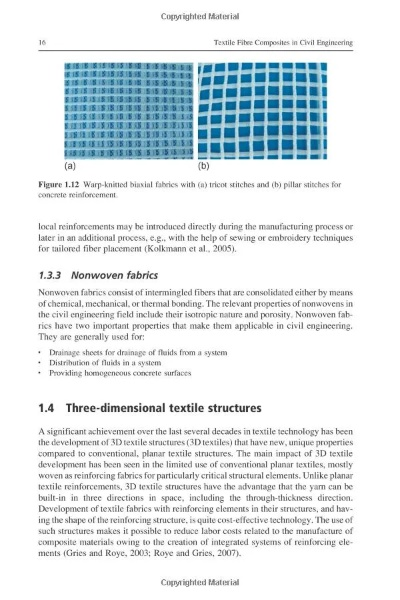

Weaving: After the fabric has been dyed, it's woven into a finished product. This step is critical as it determines the overall texture and strength of the fabric.

-

Finishing: Finally, the fabric undergoes finishing treatments to enhance its appearance and durability. This may include coatings, printing, or other finishing techniques.

Advanced Technology in Textile Batching:

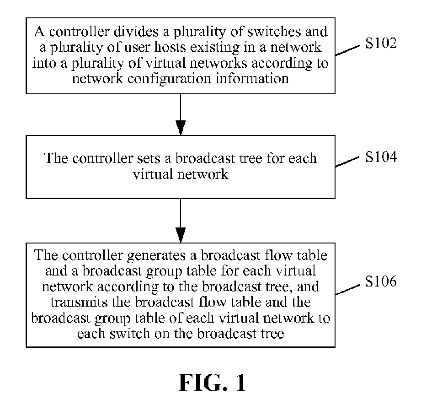

One example of advanced technology in textile batching is the use of computer-controlled machines. These machines can perform multiple operations simultaneously, reducing production time and improving efficiency. Additionally, robotic technology is being increasingly used in the textile industry, allowing for more precise and consistent work.

Quality Control:

Quality control is crucial in the textile industry, as any defects can affect the final product's appearance and performance. To ensure high-quality products, manufacturers must implement strict quality control measures throughout the entire process. This includes regular inspections of raw materials, monitoring the dyeing and weaving processes, and testing finished products for proper coloration and strength.

Benefits of Advanced Technology:

Using advanced technology in textile batching not only improves the quality of products but also reduces costs. For example, computer-controlled machines can reduce errors and increase productivity, while robotic technology can automate repetitive tasks and improve precision. Additionally, advanced technologies can help manufacturers optimize their resources and streamline their supply chain, ultimately leading to cost savings.

Conclusion: In conclusion, textile batching and processing are critical steps in the textile industry. By implementing advanced technology and implementing strict quality control measures, manufacturers can produce high-quality products that meet consumer expectations. As technology continues to evolve, we can expect even greater improvements in textile processing and batching, leading to even more efficient and cost-effective manufacturing processes.

纺织品冲床加工概述

纺织品冲床加工是现代纺织工业中的重要环节,它涉及到多个工艺流程,包括原料准备、模具设计、冲压操作等,在纺织品加工过程中,冲床起到了至关重要的作用,它能够高效、精确地完成各种复杂形状和尺寸的纺织品加工。

纺织品冲床加工工艺流程

- 原料准备:需要准备好符合要求的纺织品原料,包括纤维类型、厚度、颜色等。

- 模具设计:根据纺织品的设计要求,设计合适的模具,模具的设计需要考虑形状、尺寸、材料等因素。

- 冲压操作:使用冲床进行精确的冲压操作,根据模具的设计和要求,将纺织品进行精确的成型和加工。

- 质量控制:在整个加工过程中,需要严格把控产品质量,确保最终产品符合相关标准和要求。

纺织品冲床加工案例分析

某知名品牌纺织品加工

该品牌在纺织品冲床加工方面有着丰富的经验和先进的设备,他们采用先进的模具设计和冲压技术,能够高效、精确地完成各种复杂形状和尺寸的纺织品加工,在处理过程中,他们注重产品质量和工艺控制,确保最终产品达到相关标准和要求。

新型纺织品材料的冲压加工

近年来,新型纺织品材料的出现为纺织品冲床加工带来了新的挑战和机遇,针对新型材料的特点,他们采用了特殊的模具设计和冲压技术,能够更好地满足新型材料的需求,他们注重技术创新和工艺优化,不断提高加工效率和产品质量。

纺织品冲床加工中的注意事项

- 原料选择:在选择纺织品原料时,需要充分考虑其性能、厚度、颜色等因素,以确保最终产品符合相关标准和要求。

- 模具设计:模具设计是纺织品冲床加工的关键环节,需要充分考虑形状、尺寸、材料等因素,以确保最终产品能够达到预期效果。

- 操作规范:在纺织品冲床加工过程中,需要严格遵守操作规范,确保加工过程的安全和高效。

- 质量监控:在整个加工过程中,需要严格把控产品质量,确保最终产品符合相关标准和要求,还需要定期进行质量检测和评估,及时发现和解决问题。

英文表格补充说明

以下是一个英文表格,用于进一步说明纺织品冲床加工的相关内容:

纺织品冲床加工流程说明

| 步骤 | 描述 | 相关说明 |

|---|---|---|

| 原料准备 | 选择符合要求的纺织品原料 | 考虑纤维类型、厚度、颜色等 |

| 模具设计 | 根据纺织品设计要求设计模具 | 考虑形状、尺寸、材料等因素 |

| 冲压操作 | 使用冲床进行精确的冲压操作 | 根据模具进行成型和加工 |

| 质量监控 | 严格把控产品质量 | 定期进行质量检测和评估 |

纺织品冲床加工是现代纺织工业中的重要环节,它涉及到多个工艺流程和注意事项,在纺织品加工过程中,需要注重原料选择、模具设计、操作规范和质量监控等方面的工作,还需要不断更新设备和工艺技术,提高加工效率和产品质量,通过不断努力和创新,我们能够更好地满足市场需求,提高纺织品的附加值和市场竞争力。

Articles related to the knowledge points of this article:

Top Ten Textile Import Dyeing Agents in the Chinese Market

Top Ten Brands of Textile Waterproofing Agents in the Waterproofing Market

The Future of Textiles:An Overview of Silverdale Textiles

Implementing Tariff Reductions to Boost Global Trade and Economic Growth