Understanding the Quality Assurance in Textiles

Quality assurance in textiles is a crucial aspect of the industry, ensuring that products meet consumer expectations and regulatory standards. This process involves multiple stages, from raw material selection to final product inspection. ,The first step in quality assurance is the selection of high-quality raw materials, such as cotton or synthetic fibers. These materials are then processed into fabric through various techniques, including weaving, knitting, and crocheting. During this process, quality control measures are implemented to ensure uniformity and consistency in the finished product.,Once the fabric is produced, it undergoes further testing to determine its strength, durability, and other physical properties. This includes measuring weight, thickness, and color accuracy. Additionally, visual inspections are conducted to identify any defects or irregularities that may affect the overall quality of the product.,Finally, the finished textile is inspected for compliance with relevant regulations and standards. This includes checking for any safety hazards, such as toxic substances or lead content, and ensuring that the product meets ISO and other industry-specific standards.,In summary, quality assurance in textiles is a multi-step process that involves selecting high-quality raw materials, implementing quality control measures during processing, conducting testing to ensure physical properties and visual inspections, and finally, ensuring compliance with regulations and standards.

Introduction: Textiles, a diverse range of materials used for clothing, bedding, and other applications, are an essential part of our daily lives. From luxury designer collections to everyday wear, textiles play a crucial role in providing comfort, style, and functionality. However, with their wide variety and importance, it's essential that they meet high standards of quality. This is where quality assurance comes into play. In this article, we'll delve into the concept of textile quality assurance, its significance, and how it can be effectively implemented.

Quality Assurance in Textiles: Quality assurance in textiles refers to the systematic process of identifying, assessing, controlling, and documenting the quality of textile products to ensure they meet customer expectations and industry standards. It involves a multi-tiered approach that includes raw material inspection, production processes, final product testing, and post-production inspections.

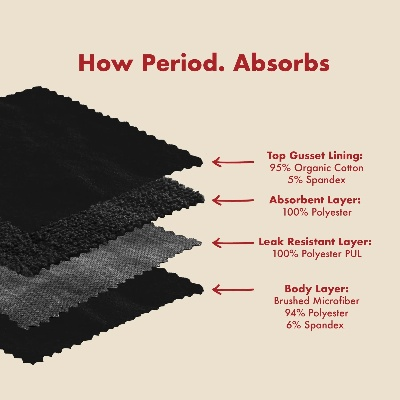

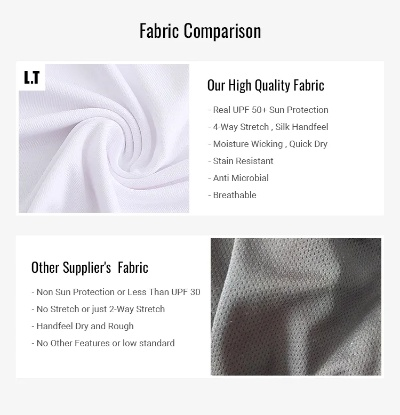

Raw Material Inspection: The first step in ensuring the quality of textiles starts with the raw materials used in their production. Raw materials like cotton, polyester, and wool are inspected for their physical properties, such as color, texture, and density. Additionally, they are tested for any contaminants or impurities that could compromise the quality of the finished product.

Production Process Control: Once the raw materials have been selected, the next stage is to control the production process. This involves monitoring the various stages of the manufacturing process, from spinning to weaving, knitting, or crocheting, to ensure consistency in quality. Quality assurance personnel will closely monitor the process to identify any deviations from the standard operating procedures (SOPs) and take corrective action if necessary.

Final Product Testing: Once the textiles have been produced, they go through rigorous testing to ensure they meet the required standards. This includes tests like colorfastness, shrinkage, tear strength, and durability. These tests help to identify any defects or flaws that may affect the product's performance or appearance.

Post-Production Inspections: Finally, post-production inspections are conducted to ensure that the final product meets all the requirements set by the manufacturer and the customers. These inspections cover areas like stitching, seams, and labels, among others. Any discrepancies found during these inspections are addressed promptly to prevent further issues.

Case Study: Consider the case of a luxury brand that produces high-end silk scarves. To ensure the quality of their products, they implement a comprehensive quality assurance program that covers every aspect of the production process. They start by conducting thorough raw material inspections to ensure that the silk used in their scarves is of high-quality and consistent in color and texture. They also monitor the production process closely, ensuring that the weaving techniques are precise and that the silk is evenly distributed across the fabric.

After the fabric has been produced, the scarves undergo rigorous testing to ensure they meet the brand's specific requirements. This includes tests for colorfastness, shrinkage, and durability. If any defects are found during these tests, the manufacturer takes immediate action to correct them before they reach the customer.

Finally, post-production inspections are conducted to ensure that each scarf meets the brand's exact specifications. Any discrepancies are identified and resolved before the scarves are shipped to customers.

By implementing a comprehensive quality assurance program like this, the luxury brand not only ensures that their products meet high standards but also builds trust with their customers. This approach not only improves the overall quality of their products but also enhances their reputation as a reliable and trustworthy brand.

Conclusion: In conclusion, quality assurance in textiles is an essential component of ensuring that textile products meet customer expectations and industry standards. By implementing a comprehensive quality assurance program that covers all aspects of the production process, manufacturers can minimize defects and ensure that their products are of the highest quality possible. The case study provided highlights the importance of a robust quality assurance program in achieving this goal.

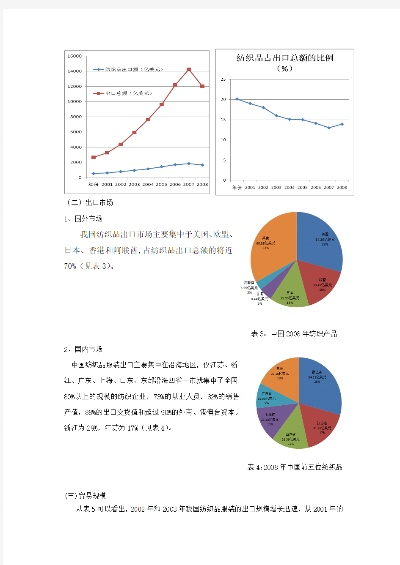

纺织品质量检测概述

纺织品质量检测是确保产品符合相关标准和消费者需求的重要环节,它涉及到对纺织品原材料、生产过程、成品的质量控制,以及产品的安全性和环保性等方面,本文将详细介绍纺织品质量检测的概念、方法和流程。

检测方法与标准

检测方法:

(1)外观检测:通过观察纺织品表面、质地、颜色等外观特征,评估其质量。 (2)化学成分分析:通过分析纺织品中的化学成分,确保其符合相关标准和安全标准。 (3)机械性能测试:通过测试纺织品的拉伸强度、弹性等机械性能,评估其耐用性和稳定性。 (4)环保性能检测:检测纺织品是否符合环保标准,如重金属含量、有害物质排放等。

检测标准:

(1)国家标准:根据不同类型纺织品的特点,制定相应的国家标准。 (2)行业规范:各行业根据自身需求和特点,制定相应的行业规范。 (3)第三方认证:对于一些重要产品,可以通过第三方认证机构进行质量检测和认证。

案例分析

以纺织品质量检测为例,我们可以从以下几个方面进行案例分析:

某品牌棉质衬衫的质量检测

该品牌棉质衬衫的质量检测主要包括外观检测、化学成分分析和机械性能测试,在外观检测中,我们主要观察衬衫的质地、颜色、纹理等外观特征,确保其符合消费者需求,在化学成分分析中,我们主要检测衬衫中的纤维成分、重金属含量等,确保其符合相关标准和安全标准,在机械性能测试中,我们主要测试衬衫的拉伸强度、弹性等机械性能,评估其耐用性和稳定性。

某品牌丝绸面料的质量检测

该品牌丝绸面料的质量检测主要包括外观检测、环保性能检测和纤维成分分析,在外观检测中,我们主要观察丝绸面料的质地、色泽、纹理等外观特征,确保其符合高端品质要求,在环保性能检测中,我们主要检测丝绸面料是否符合环保标准,如重金属含量、有害物质排放等,在纤维成分分析中,我们通过分析纤维成分,确保其符合高端面料的要求,同时符合国际环保标准。

纺织品质量检测的重要性与意义

纺织品质量检测对于保障消费者权益、提高产品质量和竞争力具有重要意义,通过质量检测,可以确保纺织品符合相关标准和安全标准,提高产品的质量和可靠性,增强消费者的信任度和满意度,高质量的纺织品也可以提高产品的附加值和市场竞争力,促进产业的发展和升级。

纺织品质量检测是确保纺织品产品质量的重要环节,通过科学的方法和流程,可以全面评估纺织品的质量和性能,确保其符合相关标准和安全标准,通过质量检测也可以提高产品的质量和可靠性,增强消费者的信任度和满意度,我们应该重视纺织品质量检测工作,加强质量控制和管理,提高产品质量和竞争力。

Articles related to the knowledge points of this article:

纺织品欧盟Reach and ASTM Standards:A Comprehensive Guide for Manufacturers

A Glimpse into Textiles:A Comprehensive Guide to Portraits of Fabric Exhibits

Exploring the Art of Handmade Textiles:A Tutorial for Beginners