Understanding and Managing Textile Water Content:A Comprehensive Guide

"Understanding and Managing Textile Water Content: A Comprehensive Guide",This comprehensive guide provides a thorough understanding of the various factors that influence textile water content, including fabric structure, wetting properties, and environmental conditions. It offers practical tips for optimizing moisture management in the textile industry, from selecting appropriate materials to designing efficient drying processes. The guide also covers the challenges associated with maintaining consistent moisture levels in textiles, such as moisture migration and dehydration during storage or transportation. By providing insights into these complex phenomena, this guide empowers textile professionals to make informed decisions and improve the overall quality and performance of their products.

Introduction: Textiles are an integral part of our daily lives, from clothing to home furnishings. One critical aspect that affects the quality, functionality, and longevity of these products is their moisture content. This guide aims to provide you with a comprehensive understanding of textile moisture testing and how it can impact your end-use performance. Let's dive into the details.

Textile Moisture Testing: Moisture testing is the process of measuring the amount of water in a textile material. It's essential for several reasons:

-

Quality Control: Moisture levels can affect the durability, color, and overall appearance of textiles. High moisture levels can cause fabrics to degrade faster, leading to reduced lifespan and poorer quality.

-

Preservation: Moisture control is crucial for maintaining textiles in optimal condition. Properly drying or ventilating materials can prevent mold growth, mildew formation, and other environmental issues.

-

Safety: Certain textiles, like medical equipment, need to be free from moisture to ensure patient safety. Knowledge of moisture content is vital for ensuring compliance with regulatory standards.

-

Environmental Impact: Reducing textile moisture can help conserve resources and reduce energy consumption during manufacturing and disposal processes.

Testing Methods: There are several methods for moisture testing textiles:

-

Absorption Testing: This method involves placing a known weight of textile on a piece of paper or a weighable surface. The paper is then weighed after a certain period to determine the amount of absorbed water.

-

Dew Point Method: This technique uses a dew point meter to measure the temperature at which a sample will reach its equilibrium moisture content. It's a more precise method but requires specialized equipment.

-

Gravimetric Moisture Balance (GMB): This method uses a balance to measure the weight difference between a dry sample and one that has absorbed a specific amount of water. It's a fast and straightforward way to estimate moisture content.

-

Karl Fischer Moisture Meter: This instrument measures the amount of moisture absorbed by a textile using a Karl Fischer reagent. It's accurate and widely used in industry.

-

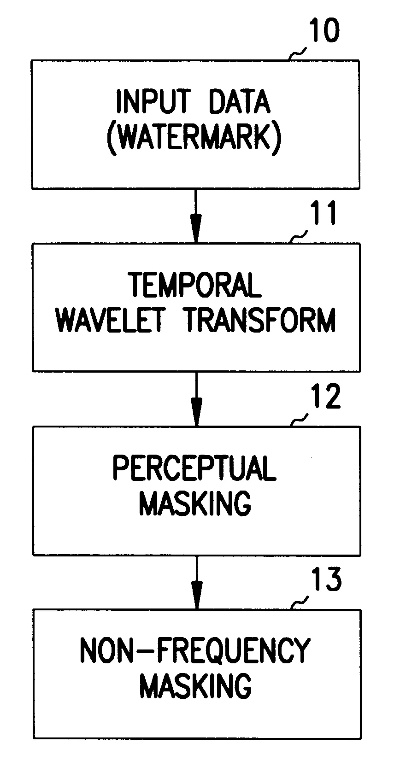

Infrared Moisture Analyzer: These instruments use infrared technology to measure the moisture content of textiles without physically contacting them. They offer high precision and portability.

Case Study: Consider a scenario where a garment manufacturer needs to ensure that their cotton shirts meet strict moisture control standards for hygiene purposes. They would likely opt for the Absorption Testing method. By placing a standardized weight on the shirt, they can determine the amount of water absorbed over a given time frame. This information allows them to adjust the production process to maintain consistent moisture levels, ensuring that the finished product meets the desired hygienic requirements.

Conclusion: Understanding and managing textile moisture content is crucial for ensuring quality, safety, and environmental sustainability. By employing the right testing methods, manufacturers can optimize their processes and comply with regulations. With the tools provided here, you can confidently assess the moisture content of any textile item and make informed decisions about its future handling and use.

纺织品水份检测的重要性

在纺织品的生产、加工和销售过程中,水份检测是一项至关重要的环节,纺织品的水份含量直接影响到其质量、性能和使用寿命,通过精确的水份检测,可以确保纺织品符合相关标准和客户的需求,提高产品质量和客户满意度。

纺织品水份检测的方法与步骤

- 准备样品:选择具有代表性的纺织品样品,确保样品具有代表性且无杂质。

- 选择检测仪器:根据样品的特点和需求,选择合适的检测仪器,如红外线水分仪、水分测定仪等。

- 进行水份检测:按照检测仪器的使用说明书,进行水份检测,通常需要设定检测参数、进行样品测试等步骤。

- 分析结果:根据检测结果,分析纺织品的水份含量是否符合标准。

案例分析

以纺织品水份检测为例,我们可以使用英文表格进行详细说明。

英文表格:

| 检测项目 | 检测方法 | 仪器型号 | 检测参数 | 结果分析 |

|---|---|---|---|---|

| 样品准备 | 选择代表性样品 | 红外线水分仪 | 设定检测范围、时间等参数 | 无杂质、代表性好 |

| 水份检测 | 使用仪器进行测试 | 根据仪器说明书进行操作 | 设置合适的检测参数,如温度、湿度等 | 水份含量是否符合标准 |

| 结果分析 | 根据检测结果判断水份含量是否符合标准 | 根据检测结果进行分析和处理 | 根据标准判断是否符合要求,如有必要可进行进一步处理 |

纺织品水份检测案例说明

以某纺织公司的纺织品为例,该公司采用红外线水分仪进行水份检测,该公司选择了一批具有代表性的纺织品样品,按照正确的操作步骤进行了水份检测,经过检测,发现该批纺织品的含水量符合相关标准和客户的需求,该公司通过精确的水份检测,提高了产品质量和客户满意度。

纺织品水份检测是确保纺织品质量的重要环节,通过选择合适的检测仪器和正确的操作步骤,可以准确、快速地检测纺织品的水份含量,在实际操作中,需要注意样品的选择和处理、检测参数的设置等细节问题,通过精确的水份检测,可以提高纺织品的质量和性能,满足客户的需求。

Articles related to the knowledge points of this article:

Textile Brands Top Ten Rankings