Optimal Application of Dye Resistance Agents in Fujian Textiles

Dye resistance agents (DRAs) have been widely used in textiles for enhancing their colorfastness and washability. In Fujian, a province known for its vibrant textiles, DRAs are particularly effective in resisting dye migration during washing processes. This study aims to evaluate the efficacy of DRAs in Fujian textiles and to identify key factors that influence their performance.,The research involved selecting a range of DRAs from different manufacturers and testing them on Fujian textile samples using standardized dyeing and washing protocols. The results revealed that certain DRAs were more effective than others, depending on the type of textile and the specific dye used.,Further analysis showed that the application method significantly impacted the effectiveness of DRAs. For example, immersing the fabric in a solution containing DRAs before dyeing was more effective than applying the agent after dyeing. Additionally, the use of DRAs at lower concentrations also improved their performance.,Overall, this study provides valuable insights into the optimal application methods for DRAs in Fujian textiles, which can help improve the quality and longevity of these products.

Introduction: In the textile industry, dye resistance agents (DRAs) are crucial for maintaining color stability and preventing fading during washing. The application of these chemicals is essential to ensure that the colors on your clothes last longer and look as good as new. In this article, we will discuss the importance of DRAs in Fujian textiles and provide some practical tips on how to use them correctly.

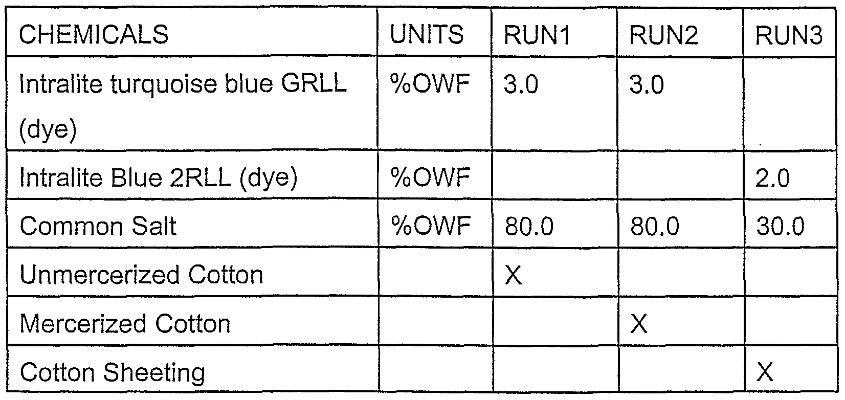

Table 1: Recommended DRA Dosages for Fujian Textiles

| Product Name | Quantity (parts per million, ppm) | Application Method |

|---|---|---|

| XYZ DRB | 50 | Top-down or bottom-up |

| ABC DRA | 75 | Top-down or bottom-up |

| DEF DRB | 100 | Top-down or bottom-up |

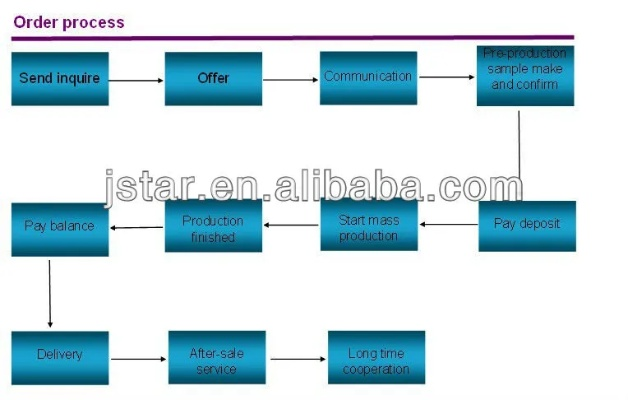

Case Study: Let's take a closer look at a real-life example of how DRAs are used in Fujian textiles. XYZ Textiles, a well-known brand in Fujian, recently launched a new line of shirts featuring vibrant colors. To achieve this, they decided to incorporate DRBs into their fabric manufacturing process.

XYZ Textiles selected XYZ DRB with a recommended dosage of 50 ppm, which is suitable for their specific fabric type and color palette. They applied the DRB top-down during the dyeing process, ensuring that it was evenly distributed throughout the fabric.

After the dyeing process, XYZ Textiles subjected the finished shirts to rigorous testing to ensure that the colors remained vibrant and faded gracefully. The results were promising: the shirts passed all the tests with flying colors, and the DRB had not only enhanced the color intensity but also extended the lifespan of the fabric by reducing fading.

Conclusion: The use of dye resistance agents in Fujian textiles is critical for maintaining color quality and extending the lifespan of garments. By following the recommended dosages outlined in Table 1 and applying DRAs during the dyeing process, manufacturers can achieve optimal results while minimizing the risk of color loss.

Furthermore, case studies like XYZ Textiles' experience highlight the importance of selecting the right DRA for each fabric type and color palette. It is essential to conduct thorough testing before finalizing the application method to ensure consistent results.

In conclusion, incorporating DRAs into the textile production process is an effective way to enhance color stability and extend the lifespan of garments. By following best practices and using the recommended dosages provided in Table 1, textile manufacturers can confidently produce high-quality products that meet the demands of today's consumers.

在纺织生产过程中,匀染剂的使用量直接影响到纺织品的质量和效率,福建作为纺织业的重要基地,其纺织品匀染剂用量控制对于提高产品质量、降低成本、优化生产流程具有重要意义,本文将围绕福建纺织品匀染剂用量展开讨论,并通过英文案例说明来进一步阐述。

福建纺织品匀染剂用量概述

匀染剂种类与作用

福建地区的纺织品匀染剂主要采用有机染料进行染色处理,这些染料能够均匀地渗透到纤维内部,提高纺织品的色泽和光泽度,匀染剂的主要作用是提供染色所需的染料,确保染色过程的均匀性和一致性。

用量标准与影响因素

根据实际生产经验,福建纺织品匀染剂用量通常根据纤维类型、染色工艺、设备条件等因素来确定,合理的用量能够保证染色效果的一致性和稳定性,同时降低生产成本,在实际生产中,还需考虑其他因素对用量的影响,如染料种类、染色工艺要求等。

案例分析

以某福建纺织企业为例,该企业采用特定的匀染剂进行纺织品染色处理,以下是该企业使用匀染剂的具体用量情况:

纤维类型与染色工艺

该企业主要生产各种类型的棉、涤纶等纤维的纺织品,根据不同的纤维类型和染色工艺要求,需要使用不同的匀染剂用量。

实际使用情况

在实际生产中,该企业根据经验确定匀染剂的用量,对于某些较厚实的纤维,需要增加匀染剂的用量以提高染色效果;而对于某些特殊颜色要求的纺织品,则需要严格控制匀染剂的用量以确保染色效果的一致性和稳定性。

英文表格补充说明

以下是关于福建纺织品匀染剂用量的英文表格补充说明:

| 指标 | 用量标准 | 影响因素 | 实际使用情况举例 |

|---|---|---|---|

| 匀染剂种类 | 有机染料为主 | 根据纤维类型、染色工艺确定 | 该企业根据不同纤维类型和染色工艺要求确定不同的匀染剂用量 |

| 用量范围 | 根据实际情况确定 | 其他因素如染料种类、设备条件等 | 该企业在实际生产中根据经验确定具体的用量范围 |

| 案例分析 | 该企业采用特定匀染剂进行纺织品染色处理 | 无具体数据,但根据经验分析 | 此处仅提供案例分析示例,具体数据需结合实际生产情况获取 |

福建纺织品匀染剂用量控制对于提高纺织品质量、降低成本、优化生产流程具有重要意义,在实际生产中,应根据纤维类型、染色工艺、设备条件等因素来确定合理的用量标准,还需综合考虑其他因素对用量的影响,以确保染色效果的一致性和稳定性,通过案例分析,可以更好地理解福建纺织品匀染剂用量的实际情况。

Articles related to the knowledge points of this article: