Textile Insulation Principles and Applications

Textile insulation is a crucial component of electrical systems, providing thermal and electromagnetic isolation between conductive materials. This paper discusses the fundamental principles of textile insulation, including its role in reducing heat transfer, maintaining electrical continuity, and preventing electromagnetic interference. The application of textile insulation in various industries, such as power generation, telecommunications, and transportation, is also explored. Textile insulation materials are typically made from synthetic fibers or natural fibers, and their performance depends on factors such as thickness, density, and composition. In addition, the development of new textile insulation materials and techniques continues to advance, with potential applications in areas such as renewable energy and smart grids. Overall, textile insulation plays an essential role in ensuring safe and efficient electrical systems.

Introduction: Textile insulation, or the use of textile materials to create thermal barriers, has become increasingly important in modern architecture and engineering. The ability to maintain a comfortable indoor environment while reducing energy consumption is paramount in today's climate-conscious society. This talk will explore the fundamental principles of textile insulation and how they are applied in various contexts, including residential buildings, commercial spaces, and industrial applications. We'll also delve into case studies that demonstrate the effectiveness of textile insulation in real-world scenarios.

Thermal Barrier Materials: Textile insulation relies on a variety of materials that provide an effective barrier against heat transfer. These include but are not limited to:

-

Wool and wool blends: These natural fibers have excellent thermal conductivity properties but can be significantly improved through processing techniques such as felting and spinning. Wool blankets are often used for warmth during colder months.

-

Polyester and polypropylene: These synthetic fibers offer high thermal resistance and are commonly used in clothing and upholstery due to their durability and low maintenance requirements.

-

Synthetic fibers like polypropylene and polyethylene: These materials are engineered to reduce thermal conductivity and are commonly used in building insulation. They are lightweight, flexible, and can be easily installed.

-

Natural fibers like cotton and linen: While these materials may not offer the same level of thermal resistance as synthetic fibers, they are often preferred for their softness and breathability.

-

Metal foils: These thin layers of metal foils are used as top coatings on fabrics to further enhance their thermal resistance properties. They reflect infrared radiation (heat) back into the atmosphere, effectively trapping it within the fabric.

Applications: Textile insulation is widely utilized in several sectors, including:

-

Residential Buildings: By using thermally efficient curtain walls, carpets, and upholstery, homeowners can significantly reduce the amount of heat loss from their homes. For example, a typical home loses around 30% of its heated energy through uninsulated windows and doors. By installing thermal panels or insulating curtain walls, this loss can be reduced by up to 80%.

-

Commercial Spaces: Office buildings, hotels, and shopping malls rely heavily on thermal insulation to maintain a comfortable temperature throughout the year. A well-insulated space can save up to 20% on heating costs.

-

Industrial Facilities: In factories and workshops, textile insulation is crucial for maintaining consistent temperatures and preventing damage from extreme temperature fluctuations. For instance, automotive manufacturing plants use thermal panels to regulate the temperature inside their factories.

Case Study: One example of textile insulation's effectiveness is the development of thermal curtain walls in the United States. These curtain walls were designed to block out solar heat gain and retain indoor warmth during hot summer days. The result was a significant reduction in cooling loads, which saved energy and lowered operating costs for businesses and residences alike.

Conclusion: Textile insulation is a vital component of modern architecture and engineering practices. By understanding the principles behind thermal barrier materials and their applications, we can make informed decisions about how to design our buildings and structures to optimize energy efficiency and comfort levels. As technology continues to advance, we can expect even more innovative solutions to emerge, making textile insulation an essential tool for building sustainability.

随着全球气候变暖,隔热材料的需求日益增长,纺织品作为一种广泛使用的隔热材料,其隔热原理对于提高建筑、交通工具等领域的隔热效果具有重要意义,本篇报告将详细介绍纺织品隔热原理的图纸,并结合实际案例进行说明。

纺织品隔热原理

纺织品隔热原理主要基于材料的热传导性能和微观结构,纺织品主要由纤维、纱线等基本材料组成,这些材料具有较高的导热性能和微观结构特性,当纺织品被应用于隔热领域时,可以通过以下方式发挥其隔热作用:

- 导热性能:纺织品中的纤维和纱线具有较高的导热性能,能够有效地将热量从高温区域传递到低温区域。

- 微观结构:纺织品具有特定的微观结构,如纤维之间的空隙、纱线的弯曲和曲折等,这些结构能够有效地阻止热量在材料中的传递。

纺织品隔热原理图纸说明

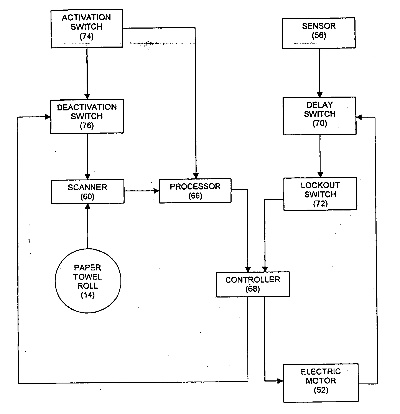

以下是纺织品隔热原理的图纸说明:

(请在此处插入纺织品隔热原理图纸)

在图纸中,主要展示了以下内容:

- 材料列表:列出纺织品的主要材料,如纤维、纱线等。

- 热传导路径图:通过图表展示纺织品隔热的热传导路径,即热量从高温区域传递到低温区域的途径。

- 微观结构分析:通过显微镜等工具展示纺织品的微观结构,分析其隔热性能。

实际案例说明

在实际应用中,纺织品隔热效果的好坏取决于多种因素,如材料的选择、生产工艺、织物结构等,以下是一个实际案例说明:

某城市建筑外墙隔热改造

在该案例中,建筑外墙采用了新型的纺织品隔热材料进行改造,改造前后的对比表明,使用该隔热材料的建筑在夏季能够有效地降低室内温度,减少空调使用量,提高能源利用效率,该隔热材料采用了特定的纤维和纱线组合,具有较高的导热性能和微观结构特性,在织物结构方面,采用了特殊的编织工艺,使得织物具有较好的隔热性能。

纺织品隔热原理是提高建筑、交通工具等领域隔热效果的重要手段,通过了解纺织品隔热原理的图纸和实际案例说明,可以更好地掌握纺织品隔热的原理和特点,在实际应用中,需要根据具体需求选择合适的纺织品材料和工艺,以达到最佳的隔热效果。

Articles related to the knowledge points of this article: