The Fabric of Innovation:An Overview of Shenyangs Textile and Dyeing Industry

Shenyang, a city in Northeast China, has been at the forefront of innovation in the textile and dyeing industry. This sector has undergone significant transformations over the past few decades, driven by technological advancements and global market demands.,One of the key drivers of this transformation has been the adoption of advanced technologies such as digital printing, which allows for high-quality, eco-friendly products to be produced quickly and efficiently. Additionally, Shenyang's textile and dyeing industry has been heavily influenced by the growing demand for sustainable and ethical materials.,As a result, many local companies have invested heavily in research and development, creating new products that meet the needs of both domestic and international markets. This has led to increased competitiveness and profitability for these businesses, while also contributing to economic growth in the region.,Overall, the Fabric of Innovation showcases the dynamic and innovative nature of Shenyang's textile and dyeing industry, demonstrating how it can continue to thrive in the face of changing market conditions and technological advancements.

Introduction: Shenyang, the capital city of Liaoning Province in Northeast China, is not just a hub for manufacturing but also a pioneer in textile and dyeing innovation. With its rich history and dynamic industry sectors, Shenyang stands as a testament to the city's commitment to sustainability, quality, and technological advancement in the global textile industry. In this article, we will delve into the fabric of innovation that underpins Shenyang's textile and dyeing industry, highlighting its key players, processes, and achievements.

Key Players: Shenyang's textile and dyeing industry is led by several major players who are at the forefront of technology, research, and innovation. These include:

- Liaoning Zhongyuan Textile Group (LZZG): Known for its high-quality products, LZZG is one of the largest textile companies in China with a strong presence in the international market.

- Shenyang Yundong Textile Co., Ltd.: A leading manufacturer of high-end textiles, Yundong specializes in eco-friendly dyeing processes.

- Shenyang Jianfeng Textiles: A subsidiary of LZZG, Jianfeng focuses on developing new materials and technologies for sustainable textile production.

- Shenyang Huayi Textile Technology Co., Ltd.: A leader in digital printing technology, Huayi offers innovative solutions for colorfastness and eco-friendliness in textiles.

- Shenyang Xinhai Dyeing & Printing Machinery Co., Ltd.: As an equipment manufacturer, Xinhai provides advanced machinery for dyeing and printing processes.

Processes: The textile and dyeing process in Shenyang involves a series of steps from raw material procurement to finished product assembly. Here's how it works:

- Raw Material Procurement: Shenyang textile manufacturers source cotton, polyester, acrylic, and other natural and synthetic fibers from around the world.

- Pretreatment: Before dyeing, the raw materials undergo treatments such as desizing, scouring, and bleaching to remove impurities and enhance color fastness.

- Dyeing Process: Shenyang's textile companies employ various dyeing methods, including pad-dry-cure, pad-wet-cure, and pad-free techniques, to achieve vibrant colors.

- Finishing: After dyeing, textiles undergo finishing processes like printing, embroidery, and trimming to enhance their appearance and functionality.

- Packaging and Distribution: Finally, the finished products are packaged and shipped to retailers or exported to international markets.

Achievements: Shenyang's textile and dyeing industry has made significant strides in recent years, achieving notable accomplishments:

- Sustainability: Shenyang's textile companies have embraced sustainable practices, reducing water usage, energy consumption, and waste generation through advanced recycling and processing methods.

- Technological Innovation: The city's textile firms invest heavily in R&D, leading to breakthroughs in dyeing techniques, such as eco-friendly dyeing and smart dyeing systems that improve color accuracy and reduce toxicity.

- Brand Expansion: Shenyang's textile brands have expanded globally, establishing strong footholds in Europe, the United States, and other regions.

- Quality Standards: The city's textile products adhere to strict international quality standards, ensuring consumers worldwide receive consistent quality across different markets.

Case Study: One example of Shenyang's textile and dyeing industry success is the collaboration between LZZG and the University of Science and Technology of China (USTC). The two institutions have been working on developing a new type of eco-friendly dyeing technology that reduces water pollution while maintaining high color intensity. This breakthrough has led to the creation of a range of sustainable textile products that are gaining popularity among consumers and investors alike.

Conclusion: Shenyang's textile and dyeing industry is a testament to the city's commitment to innovation, sustainability, and global competitiveness. With its robust industrial base, cutting-edge technology, and dedication to environmental stewardship, Shenyang stands at the forefront of the global textile industry. As the industry continues to evolve, it remains a beacon of hope for those looking to build a more sustainable future through textiles.

沈阳针纺织品印染概述

沈阳作为东北地区的纺织重镇,其针纺织品印染工艺历史悠久,独具特色,印染技术不仅体现了当地人民的智慧和勤劳,更是沈阳地区文化传承的重要载体,本文将通过介绍沈阳针纺织品印染的特点、工艺流程以及案例分析,让读者更深入地了解这一传统工艺。

沈阳针纺织品印染特点

传统工艺与现代技术的完美结合

沈阳针纺织品印染工艺融合了传统的手工技艺和现代的技术手段,形成了独特的风格和特点,在材料选择上,注重使用环保、可降解的材料,减少对环境的污染,在印染技术方面,采用先进的染色技术、印花技术等,提高了印染产品的质量和效率。

色彩丰富、图案多样

沈阳针纺织品印染产品色彩丰富,图案多样,不同的面料采用不同的印染工艺,如丝光、提花、刺绣等,使得产品具有独特的风格和魅力,随着时代的发展,新的印花图案和颜色不断涌现,满足了消费者对时尚和个性的追求。

沈阳针纺织品印染工艺流程

-

材料准备:选择合适的面料和染料,进行预处理。

-

染色:采用高温染色或低温染色等方法,将面料染色。

-

印花:根据图案设计,采用印花技术将图案印在面料上。

-

整理:对印染产品进行整理,使其达到一定的平整度和光泽度。

案例分析

以某知名针纺织品品牌为例,介绍沈阳针纺织品印染的实践应用,该品牌在针纺织品印染方面有着丰富的经验和独特的工艺流程。

-

材料选择:该品牌选择环保、可降解的材料作为主要材料,同时注重面料的质量和手感。

-

染色工艺:采用先进的染色技术,使得产品具有鲜艳的色彩和良好的光泽度,该品牌注重颜色的搭配和层次感,使得产品具有丰富的视觉效果。

-

印花工艺:该品牌采用多种印花技术,如丝光印花、提花印花等,使得产品具有独特的风格和魅力,该品牌注重图案的设计和创新,使得产品具有时尚感和个性化。

-

后续处理:该品牌对印染产品进行整理和烘干等处理,使其达到一定的平整度和光泽度,该品牌注重产品的包装和运输,确保产品的质量和安全。

英文表格补充说明

以下是英文版本的针纺织品印染工艺流程表格:

| 步骤 | 描述 | 示例说明 |

|---|---|---|

| 材料准备 | 选择面料和染料 | 选择环保、可降解的材料 |

| 染色工艺 | 采用高温染色或低温染色等方法 | 采用先进的染色技术,使得产品具有鲜艳的色彩和良好的光泽度 |

| 印花工艺 | 采用多种印花技术 | 采用丝光印花、提花印花等 |

| 后续处理 | 进行整理和烘干等处理 | 对印染产品进行整理和烘干等处理 |

沈阳针纺织品印染工艺是当地文化传承的重要载体,也是当地人民智慧和勤劳的结晶,随着时代的发展,沈阳针纺织品印染工艺也在不断创新和发展,为当地经济发展和文化传承做出了重要贡献。

Articles related to the knowledge points of this article:

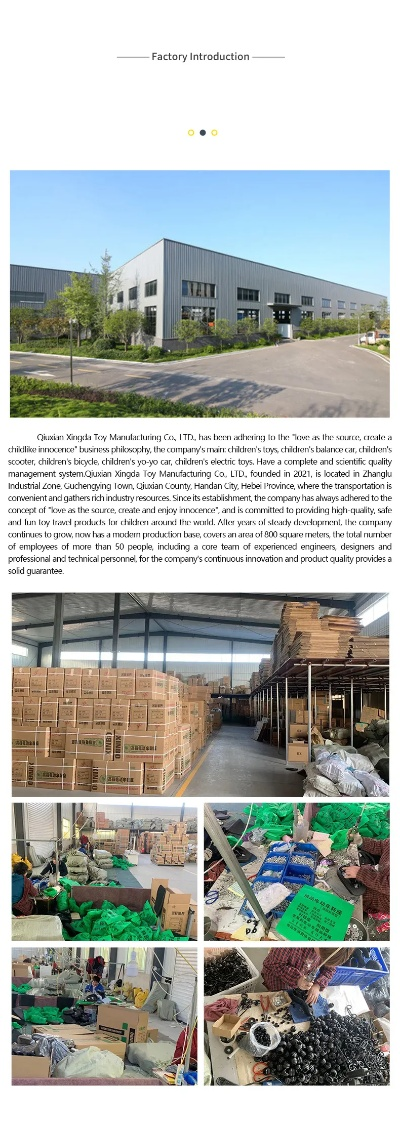

A Glimpse into Ruiyang Textiles Factory

The 2016 National Textile Manufacturers:An Overview

The Role of the National Textile Supervision and Testing Center