Textile Defect Detection Methods:A Comprehensive Guide

This article provides a comprehensive guide on textile defect detection methods. It discusses various techniques used to identify and rectify defects in textile products, including visual inspection, non-destructive testing, and eddy current testing. The article also covers the importance of proper training for technicians who perform these tests and the potential benefits of using advanced technology in detecting defects. Overall, this article aims to provide readers with a thorough understanding of the different methods available for detecting textile defects and how to effectively use them to improve product quality and reduce costs.

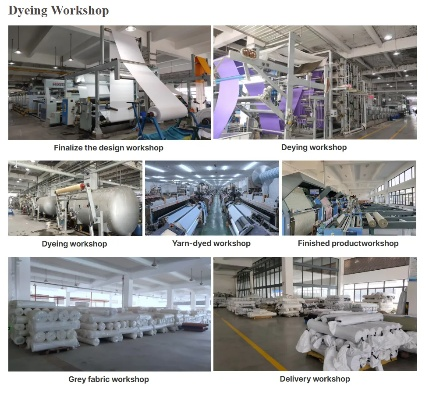

Introduction: Textile products, such as clothing, upholstery, and other textile materials, are essential for daily life. However, their production process involves various stages where defects can occur, leading to poor quality or safety concerns. Therefore, the detection of these defects is crucial for ensuring the quality and safety of textile products. In this article, we will discuss different methods used in textile defect detection, including visual inspection, instrumental testing, and machine learning-based techniques. We will also provide an example of a real-world case study to demonstrate how these methods can be applied in practice.

Visual Inspection: Visual inspection is the most common method used in textile defect detection. It involves examining the product under a microscope or using specialized tools to detect any visible defects such as fraying, pilling, color variations, or missing yarns. This method is simple and cost-effective, but it may not be able to detect all types of defects or small ones that are difficult to see.

Instrumental Testing: Instrumental testing uses specialized equipment to measure the properties of the textile material. For example, the breaking strength test measures the maximum force required to break a sample of fabric, while the tear resistance test measures how well the fabric resists tearing. These tests can help identify defects such as weak spots, excessively thick or thin areas, or areas with poor stitching.

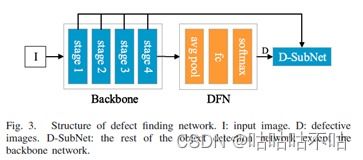

Machine Learning-Based Techniques: Machine learning-based techniques use algorithms to analyze large amounts of data and identify patterns that indicate potential defects. These techniques are becoming increasingly popular in the textile industry, as they can quickly and accurately detect defects that may not be visible to the human eye. Some examples of machine learning-based techniques include image recognition, deep learning, and neural networks.

Case Study: One example of a real-world case study is the detection of defects in high-quality cotton fabrics during the manufacturing process. The manufacturer used a combination of visual inspection and instrumental testing to identify any defects in the fabric. However, they found that some defects were missed using these methods due to their small size or subtle nature. To address this issue, the manufacturer implemented machine learning-based techniques to detect defects more accurately. They trained a neural network to recognize patterns in images of the fabric and flagged any areas that were likely to have defects. This led to a significant reduction in the number of defective fabrics produced, resulting in improved customer satisfaction and reduced costs.

Conclusion: Textile defect detection is critical for ensuring the quality and safety of textile products. Different methods are available for detecting defects, including visual inspection, instrumental testing, and machine learning-based techniques. While each method has its limitations, combining multiple methods can provide a comprehensive approach to detecting defects in textile products. As technology continues to advance, we can expect to see even more sophisticated methods being developed to improve the accuracy and efficiency of defect detection in the textile industry.

随着纺织品的广泛应用,其质量检测显得尤为重要,本文将详细介绍纺织品的缺陷检测方法,并通过案例分析进一步说明其实际应用。

纺织品的缺陷检测方法

外观检测

(1)颜色检测:通过观察纺织品颜色是否均匀、鲜艳,判断其是否存在色差或褪色现象。

(2)纤维含量检测:通过称重、拉力测试等方法,检测纺织品纤维含量是否符合标准。

(3)织物结构检测:通过观察织物的纹理、密度、质地等,判断其是否存在瑕疵或缺陷。

机械性能检测

(1)拉伸强度检测:通过拉伸试验机对纺织品进行拉伸测试,观察其是否符合规定的拉伸强度标准。

(2)耐磨性检测:通过模拟使用环境,观察纺织品在特定磨损条件下的表现,判断其耐磨性能是否达标。

化学成分分析

(1)成分含量分析:通过化学分析仪器对纺织品中的化学成分进行测定,确保其符合相关标准。

(2)残留物分析:对于可能含有有害物质的纺织品,进行残留物分析,确保其安全无害。

数字化检测技术

(1)光谱分析:利用光谱分析技术对纺织品进行成分分析,提高检测精度和效率。

(2)大数据与人工智能应用:利用大数据和人工智能技术进行数据分析,提高检测的准确性和效率。

案例分析

纺织品外观缺陷案例

(1)某品牌棉质衬衫,颜色均匀鲜艳,但存在轻微色差,经过外观检测,发现纤维含量符合标准。

(2)某品牌丝绸面料,纹理清晰,质地柔软,但存在轻微瑕疵,经过外观检测和机械性能检测,发现该面料符合标准。

纺织机械性能缺陷案例

(1)某品牌牛仔布,经过拉伸强度测试发现强度不足,需要进行修复处理,经过机械性能检测和修复处理后,产品性能得到提升。

化学成分分析案例

(1)某品牌羊毛毛衣,经过成分含量分析和残留物分析发现其中含有少量有害物质,经过化学成分分析和安全处理后,产品符合安全标准。

总结与展望

纺织品的缺陷检测是确保产品质量的重要环节,通过采用多种检测方法和技术手段,可以有效地发现纺织品中的缺陷和问题,随着科技的不断进步和应用,纺织品的缺陷检测将更加智能化、精准化和高效化,对于纺织品的安全性和环保性也将越来越受到重视。

Articles related to the knowledge points of this article:

Unveiling the Future of Textiles with Graphene Technology

The Role of Textiles in the Continuous Transition from Industry to Industry

Transformative Apparel:The American Retro Look in Fashion

Limitations in the Collection of Waste Textiles:A Call to Action