The Dynamics of Textile Profitability

The study explores the dynamics of textile profitability, examining how different factors such as market demand, production costs, and technological advancements influence the profitability of textile companies. The research highlights the importance of understanding these dynamics in order to optimize production processes and improve profitability. It also suggests that companies should invest in research and development to stay ahead of the competition and meet changing consumer preferences. Overall, the study provides valuable insights into the complex interplay between various factors that contribute to the profitability of textile companies.

Introduction: In the world of textile production, understanding the complexities of profitability is crucial for both manufacturers and retailers alike. Profitability is not just a mathematical concept; it's a reflection of the value a company can extract from its operations, products, and services. In this article, we will delve into the various factors that contribute to the profitability of textiles, including raw material costs, labor expenses, manufacturing processes, marketing strategies, and competition in the market. We will also present an illustrative table outlining the typical cost structure of a textile product and highlight some successful case studies to illustrate how these elements come together to drive profitability.

Cost Analysis: The cost structure of a textile product is multifaceted, with each component contributing to the overall profitability. Here's a simple table summarizing the typical costs involved:

| Cost Type | Description | Unit Cost (USD) |

|---|---|---|

| Raw Materials | Includes cotton, polyester, yarn, etc. | $10/kg |

| Labor | Direct labor required for production, such as weaving, knitting, etc. | $50/hour |

| Manufacturing | Expenses related to machinery, energy, and other overheads | $20/unit |

| Packaging | Boxes, bags, or other containers needed to protect the product during transportation | $0.50/piece |

| Marketing | Sales promotion, advertising, and distribution expenses | $200,000/year |

| Distribution | Shipping costs, handling fees, and any taxes associated with moving goods internationally | $10/kg |

| Research & Development | Continuous innovation in new materials and designs | $10,000/project |

| Warranty | Coverage provided by manufacturers for defects in materials or workmanship | Free |

For example, a basic textile product might have a cost of $10 per kilogram for raw materials, labor costs of $50 per hour, and manufacturing expenses of $20 per unit. If packaging adds another $0.50 per piece, and marketing expenses are $200,000 annually, the total cost for producing one unit of the product could be $113.50. However, if the manufacturer offers a lifetime warranty at no additional cost, this could significantly increase perceived value and potentially boost profitability.

Marketing Strategies: Effective marketing plays a vital role in driving profitability in the textile industry. Companies must understand their target audience and tailor their messaging accordingly. For instance, a luxury brand like Hermès might focus on exclusivity and sophistication, while a mass-market brand like Zara might emphasize affordability and timeliness.

Case Study: One successful example of a textile company leveraging marketing strategies to boost profitability is Patagonia. The outdoor gear company has built a strong brand around its commitment to sustainability and ethical sourcing. By communicating its values and promoting eco-friendly practices through its marketing campaigns, Patagonia has been able to attract customers who are willing to pay a premium for its products. This strategy has not only increased sales but also contributed to the company's reputation as a leader in sustainable fashion.

Conclusion: Understanding the dynamics of profitability in the textile industry requires a comprehensive analysis of various factors, including raw material costs, labor expenses, manufacturing processes, marketing strategies, and competitive landscape. By examining the cost structure of a textile product and considering marketing strategies, companies can optimize their operations and maximize profits. As shown in the table above, even minor adjustments in these areas can have a significant impact on overall profitability. With careful planning and execution, textile manufacturers can achieve long-term success and build a profitable business model that meets the demands of today's global marketplace.

随着纺织业的快速发展,纺织品毛利润成为了众多商家关注的焦点,本文将围绕纺织品毛利润展开讨论,通过案例分析、图表说明等方式,帮助读者深入了解纺织品毛利润的构成和影响因素。

纺织品毛利润概述

纺织品毛利润是指纺织品在销售过程中所获得的利润,是纺织企业经济效益的重要体现,它主要包括原材料成本、生产成本、销售价格、市场行情等多个因素,在纺织品市场中,毛利润的高低直接关系到企业的盈利能力和市场竞争力。

纺织品毛利润的构成

- 原材料成本:这是纺织品毛利润的基础,主要包括棉花、蚕丝、涤纶等主要原材料的成本。

- 生产成本:包括纺织过程中的机械折旧、人工成本、能源消耗等费用。

- 销售价格:这是影响纺织品毛利润的关键因素,取决于市场需求、竞争状况等因素。

- 市场行情:随着全球纺织市场的变化,市场行情也会对毛利润产生影响。

纺织品毛利润的影响因素

- 原材料价格:原材料价格波动会对毛利润产生直接影响,棉花价格的上涨会导致纺织品毛利润下降。

- 生产成本:生产成本的高低直接影响到毛利润的多少,合理的成本控制和优化可以降低生产成本,提高毛利润。

- 市场需求:市场需求的变化也会对毛利润产生影响,当市场需求增加时,企业可以通过提高产量和销售价格来获取更多的毛利润。

- 竞争状况:在竞争激烈的市场环境中,企业需要采取有效的营销策略来提高毛利润率,通过提高产品质量、降低价格等方式来吸引消费者。

案例分析

以某知名纺织品品牌为例,分析其在纺织品毛利润方面的表现,该品牌在原材料采购方面严格控制品质和成本控制,同时注重研发新产品以提高市场竞争力,在生产成本方面,该品牌通过优化生产流程和提高生产效率来降低生产成本,在销售价格方面,该品牌根据市场需求和竞争状况进行灵活调整,以提高毛利润,该品牌还注重品牌建设和营销推广,以提高品牌知名度和美誉度,通过这些措施,该品牌在纺织品毛利润方面取得了较好的表现。

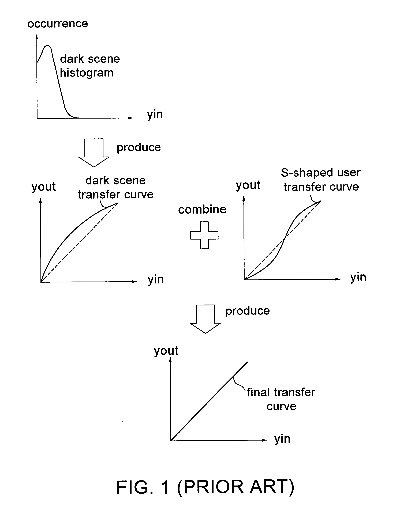

图表说明

以下是纺织品毛利润的相关图表说明:

(请在此处插入图表)

通过图表可以直观地展示原材料成本、生产成本、销售价格等关键指标的变化趋势和影响因素,这些图表可以帮助读者更好地了解纺织品毛利润的构成和影响因素。

纺织品毛利润是纺织企业经济效益的重要体现,它受到多个因素的影响,在纺织品市场中,企业需要采取有效的措施来提高毛利润率,严格控制品质和成本控制、注重研发新产品和提高市场竞争力、灵活调整销售价格等,企业还需要注重品牌建设和营销推广,以提高品牌知名度和美誉度,通过这些措施,企业可以在纺织品市场中取得更好的业绩和发展。

Articles related to the knowledge points of this article:

The Review of the EUROSTUDY Textile Brand and Its Price

Understanding the Art and Science Behind Textile Production

The Price Dynamics of Lavender Textile Products:A Comprehensive Look