The Fabric of Our Future:A Day in the Life of a Textile Mill

: The Fabric of Our Future: A Day in the Life of a Textile Mill,The fabric of our future is woven with threads of innovation and sustainability. On a typical day at a textile mill, workers transform raw materials into high-quality textiles that meet the needs of modern society. From start to finish, each step is carefully crafted to ensure the end product meets stringent environmental and social standards.,The morning begins with a thorough inspection of the raw materials. Quality control measures are implemented to ensure only the highest quality fibers are used. This process is critical as it directly impacts the final product's durability and longevity.,As the day progresses, machines begin to spin the fibers into yarns. The precision and accuracy of these operations are vital to the success of the textile mill. The team works tirelessly to maintain consistent quality and productivity throughout the day.,In the afternoon, the finished textiles undergo further processing before being packaged for distribution. Each step of this process is carefully monitored to ensure no defects are introduced during the manufacturing process.,The day ends with a thorough review of the work completed and any necessary adjustments. The focus on sustainability and innovation ensures that the textile mill continues to be a leader in its industry.,Through this day in the life of a textile mill, we can see the intricate interplay between technology, creativity, and responsibility that is essential to creating a sustainable future.

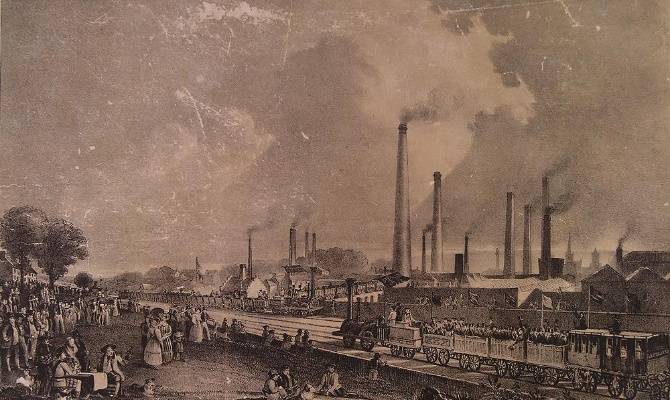

Introduction: In the heart of every bustling city lies a beacon of industry, where threads of innovation and craftsmanship converge to weave the fabric of our world. Today, I'm taking you on a virtual tour of our textile mill, where each spool of yarn is transformed into a masterpiece that resonates with the spirit of progress and sustainability. Let's dive into the rhythmic hum of production, the precision of craftsmanship, and the stories behind the fabric.

Morning Breeze: As the sun rises over the horizon, the textile mill comes alive with the sound of clanging metal and the hum of machinery. At 7:00 AM, the factory bell rings, signaling the start of another productive day. Workers don their safety gear and step into the vast expanse of the mill, ready to tackle the challenges that await them.

Production Lines: The textile mill is a veritable assembly line of sorts, with each worker contributing their unique skills to the collective effort. Here, we have a multi-layered system of machines that transform raw materials into finished products. The first stage involves carding, where flax or cotton fibers are gently teased apart. Next, the fibers are twisted together to form strands, which are then spun into yarn. This spinning process is where the magic happens, as the yarn becomes stronger and more durable with each revolution.

Quality Control: Quality control is not just an afterthought at our mill. It's a top priority, and every step of the process is scrutinized for perfection. From measuring the thickness of the yarn to checking the color consistency, every detail counts. If any product fails quality control, it's sent back to the previous stage for rework. This rigorous approach ensures that every thread is of the highest quality, ready to be woven into garments or used in various other applications.

Weaving Together: Once the yarn has been spun and tested, it's time to take it from the mill floor and onto the loom. Here, skilled weavers use a shuttle to ply the warp and weft threads together, creating intricate patterns. The loom's wooden beams creak under the weight of the heavy looms, but they remain steady as workers work tirelessly to create beautiful designs.

Finishing Touches: Once the fabric is complete, it's time for finishing touches. Here, we see a team of seamstresses carefully stitching edges, adding buttons, and finishing off any loose ends. These finishing techniques enhance the overall aesthetic appeal of the garment, making it stand out in a crowded market.

Export Success: Our textile mill's products are not just limited to domestic markets. They find their way into international trade, reaching far-flung corners of the globe. Each piece tells a story of craftsmanship and sustainability, reflecting the values we hold dear. Whether it's a cozy sweater for a cold winter night or a sleek suit for a business meeting, our textiles are a testament to our commitment to excellence and innovation.

Sustainable Practices: At our mill, we believe in being good stewards of the environment. We use recycled water and energy-efficient lighting, and we're constantly exploring new ways to reduce our carbon footprint. By adopting sustainable practices, we not only protect the planet but also set a precedent for other industries to follow.

Conclusion: As we close this chapter of our textile mill's day, we can't help but feel a sense of pride in what we do. Each thread we spin and each garment we weave is a testament to our dedication to crafting beauty and sustainability. And as we look forward to another day filled with production, quality control, and finishing touches, we know that our legacy will continue to inspire generations to come. So let's keep striving towards excellence and innovation, for in the end, it's not just about the fabric, but about the spirit that binds us all together.

纺织厂生产日常概述

在繁忙的纺织厂中,每一天都充满了生产活动的日常,从原材料的采购到产品的检验,再到最后的出货,每一个环节都紧密相连,共同构成了纺织厂的完整生产流程,下面我们将从多个方面详细描述纺织厂的生产日常。

原材料采购与检验

原材料采购

在纺织厂的生产过程中,原材料是基础,每天,采购部门都会根据生产计划和市场需求,采购各种类型的原材料,他们通过与供应商的紧密合作,确保原材料的质量和供应的稳定性。

某日采购部门收到了一份关于新材料的订单,他们立即开始与供应商进行沟通,了解材料的特性、质量标准和交货时间等信息,经过仔细筛选和比对,采购部门最终选择了符合质量要求且供应稳定的原材料。

原材料检验

原材料检验是确保产品质量的重要环节,在纺织厂,检验人员会对采购回来的原材料进行严格的检验,包括外观检查、尺寸检测、性能测试等,通过这些检验,可以及时发现并处理不合格原材料,避免对后续生产造成影响。

在某次原材料检验中,发现了一批次品布料,检验人员立即对布料进行了详细检查,并记录了问题所在,随后,他们与生产部门进行了沟通,确定了解决方案并迅速进行了处理。

生产流程与操作

生产流程

纺织厂的生产流程主要包括原料准备、织造、染整和成品检验等环节,每个环节都有专业的技术人员和操作工人在进行细致的操作。

在织造环节,技术人员会根据设计图纸和客户要求,选择合适的织机进行织造,在染整环节,工作人员会对织物进行染色、印花等处理,以提升织物的外观和质量,成品检验环节则是对整个生产过程的质量进行最后的把关。

生产操作规范

为了确保生产过程的顺利进行和产品质量的一致性,纺织厂制定了严格的生产操作规范,这些规范包括操作流程、安全防护、设备维护等方面的要求。

在操作过程中,工作人员需要严格遵守安全操作规程,佩戴防护用品,避免发生意外事故,纺织厂还定期对设备进行维护和保养,确保设备的正常运行和延长使用寿命。

案例分析:高效生产与质量控制

在某纺织厂中,他们采用了先进的生产技术和质量控制方法,实现了高效生产和高质量控制的完美结合,下面我们将通过一个案例进行分析。

某日,该纺织厂接到了一份新的订单,订单中要求使用新型面料进行制作某种产品,为了满足订单要求并确保产品质量,该厂采取了以下措施:

该厂加强了原材料的采购和检验工作,确保原材料的质量符合要求;该厂还采用了先进的织造技术,提高了织物的质量和产量,在织造过程中,该厂严格控制了每个环节的质量控制点,确保产品质量的一致性。

该厂还建立了严格的生产流程和操作规范,制定了详细的操作流程图和安全防护措施,该厂还定期对设备进行维护和保养,确保设备的正常运行和延长使用寿命,这些措施的实施使得该厂的生产效率和产品质量都得到了显著的提升。

表格补充说明(可选)

以下是纺织厂生产过程中的一些表格补充说明:

表格1:原材料采购信息表

| 原料名称 | 供应商名称 | 采购日期 | 质量标准 | 采购数量 | 备注 |

|---|---|---|---|---|---|

| 棉纱 | A公司 | X月X日 | 高品质 | 若干吨 | 已与供应商签订长期合作协议 |

| 涤纶丝 | B公司 | Y月Y日 | 符合国家标准 | X吨 | 已与供应商签订质量保证协议 |

| 其他材料 | C公司 | Z月Z日 | 根据需求定制 | 根据实际需求确定数量 | 确保满足生产需求和质量标准 |

表格2:生产流程图(示例)

| 步骤名称 | 负责人/操作人员 | 时间安排 | 设备/工具 | 备注 |

|---|---|---|---|---|

| 原材料准备 | 技术人员A | X月X日至X月XX日 | 设备A、B等 | 根据设计图纸和客户需求进行准备 |

| 织造工序 | 织机工/技术人员B等 | X月XX日至X月XX日/每天定时进行 | 织机等设备 | 按照设计图纸进行织造操作 |

| 染整工序 | 染整工/技术人员C等 | X月XX日至X月XX日/每天定时进行 | 设备染整剂等 | 对织物进行染色、印花等处理以提高质量 |

| 成品检验 | 质量检查员D等 | X月XX日至X月XX日/每天定时进行 | 质量检测仪器等设备 | 对成品进行质量检测以确保符合标准要求 |

通过以上表格补充说明和案例分析可以看出,纺织厂在生产过程中注重各个环节的质量控制和管理,采用先进的生产技术和质量控制方法,实现了高效生产和高质量控制的完美结合,他们还注重与供应商的合作和沟通,确保原材料的质量和供应的稳定性,这些措施的实施不仅提高了生产效率和质量水平,也为纺织行业的发展做出了积极的贡献。

Articles related to the knowledge points of this article:

Exploring the Future of Textile Innovation with Fenghui Textile Factory

The Beauty of a Textile Factory Girls Hair

A Night of Fire and Fury at the Shaoxing Textile Factory