The Art of Quality Control in Textiles

: The Art of Quality Control in Textiles,Quality control is a critical aspect of textile production, ensuring that the end product meets consumer expectations and industry standards. In this article, we explore the various techniques used in quality control for textiles, including inspection, testing, and quality assurance procedures. ,Inspection is the first step in quality control, where workers carefully examine each piece of fabric for defects such as holes, tears, or irregularities. This process involves close attention to detail and a keen eye for detail, as even small imperfections can compromise the overall quality of the product. ,Testing is another essential component of quality control, which involves using specialized equipment to measure various properties of the fabric, such as its strength, durability, and colorfastness. These tests help identify any flaws or deficiencies in the manufacturing process, allowing manufacturers to make necessary adjustments before final assembly. ,Finally, quality assurance procedures involve implementing rigorous quality management systems that ensure consistent performance across all stages of the production process. These systems include regular audits, training programs, and reporting mechanisms that allow manufacturers to monitor and improve their processes over time. ,In conclusion, the art of quality control in textiles involves a combination of inspection, testing, and quality assurance procedures that work together to ensure that each piece of fabric meets high standards of excellence. By adopting these techniques, manufacturers can build trust with customers and achieve long-term success in the competitive textile industry.

Good morning everyone,

Today I'm going to talk about the importance of quality control in textiles. Quality control is an essential aspect of any manufacturing process, and it plays a crucial role in ensuring that products meet the desired standards and expectations. In the case of textiles, this means not only meeting physical specifications but also ensuring that the finished product is safe for use, free from harmful chemicals, and conforms to international standards.

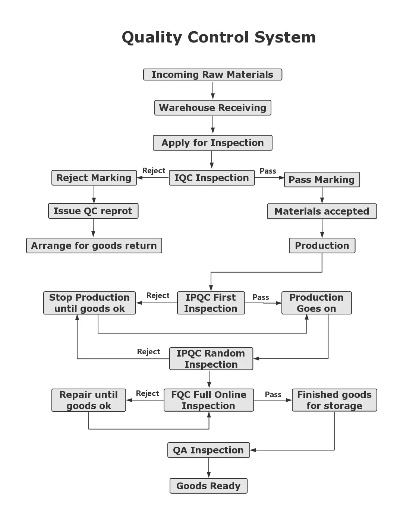

To begin with, let's take a look at the different stages of quality control in textiles. These stages are as follows:

-

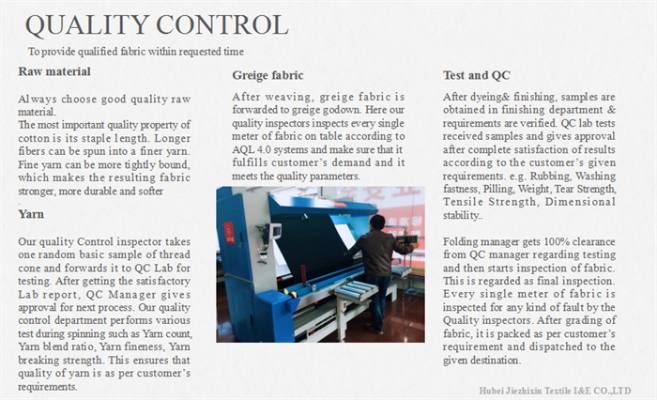

Raw Material Inspection: This is the first step in the production process. Inspectors check the raw materials for any defects or contaminants that could affect the final product. For example, if a fabric has a high level of dye-bleeding, it will result in discoloration when washed.

-

Fabric Production: Once the raw materials have been inspected, they go on to be woven into fabric. During this stage, quality control checks for uniformity, strength, and consistency in the weave pattern. For instance, a standard twill weave should have a consistent width across the width of the fabric.

-

Finishing Processes: After the fabric is produced, it undergoes various finishing processes such as dying, printing, and finishing. During this stage, quality control checks for any defects or imperfections that may occur during these processes. For example, if a fabric has uneven dye coverage, it may not look uniform after washing.

-

Packaging and Shipping: Finally, the finished product is packaged and shipped to customers. During this stage, quality control checks for any damage or defects that may occur during transportation. For example, if a package is dropped during shipping, it may result in damage to the fabric inside.

Now, let's take a look at some examples of textile quality control cases.

One example is the case of a company that produces clothing using polyester fabric. They had to ensure that the fabric was free from any harmful chemicals. To achieve this, they used a combination of chemical testing and visual inspection. Chemical testing involved analyzing the fabric for any residual chemicals that could cause skin irritation or allergic reactions. Visual inspection involved checking the fabric for any visible defects such as holes or tears. By following these measures, the company was able to produce clothing that met their customers' needs and expectations while also ensuring their safety.

Another example is the case of a textile company that produces carpets using wool fibers. They had to ensure that the carpets were free from any harmful chemicals. To achieve this, they used a combination of chemical testing and visual inspection. Chemical testing involved analyzing the carpets for any residual chemicals that could cause respiratory problems or allergic reactions. Visual inspection involved checking the carpets for any visible defects such as holes or tears. By following these measures, the company was able to produce carpets that met their customers' needs and expectations while also ensuring their safety.

In conclusion, quality control is an essential aspect of any manufacturing process, and it plays a crucial role in ensuring that products meet the desired standards and expectations. By following proper quality control procedures, companies can produce products that are safe for use, free from harmful chemicals, and conform to international standards. As we continue to advance in technology and improve our manufacturing processes, it is important that we continue to prioritize quality control as a key factor in achieving success in the textile industry. Thank you for listening!

大家好,今天我们将围绕纺织品质检的主题展开讨论,纺织品作为日常生活中不可或缺的物品,其质量直接关系到人们的穿着舒适度和安全性,对纺织品进行严格的质量检测是确保其符合相关标准和法规的重要手段。

纺织品质检是确保纺织品质量的重要环节,通过质检,可以确保纺织品符合国家或行业标准,满足使用要求,保障人们的穿着安全和健康,通过质检还可以提高纺织品的市场竞争力,促进纺织行业的发展。

纺织品质检的流程

- 样品采集:从市场或生产厂家收集待检测的纺织品样品。

- 样品检测:对样品进行各项检测指标的测试,包括纤维成分、尺寸稳定性、耐洗色牢度、耐摩擦色牢度等。

- 数据记录与分析:将检测结果进行记录和分析,形成质检报告。

- 报告出具:根据检测结果出具质检报告。

案例分析

以某品牌纺织品为例,其质检流程如下:

- 样品采集:从该品牌的生产线上收集了一批待检测的纺织品样品。

- 样品检测:对该批样品进行了纤维成分测试、尺寸稳定性测试、耐洗色牢度测试、耐摩擦色牢度测试等,根据测试结果,发现样品存在一些问题,如某些纤维成分不符合标准等。

- 数据记录与分析:将检测结果进行记录和分析,形成详细的质检报告,报告中指出,该批次纺织品存在一些问题,需要进行整改,根据报告结果,为该品牌提供了改进建议和措施。

质检案例说明

在纺织品质检中,我们可以通过一些具体的案例来说明,某地区的一家纺织厂在生产过程中出现了纤维含量不达标的情况,导致产品质量不符合国家标准,针对这种情况,该纺织厂采取了整改措施,加强了原材料的控制和管理,提高了生产过程中的质量控制水平,该纺织厂还加强了与供应商的合作,确保原材料的质量符合要求,经过整改和改进措施的实施,该纺织厂的产品质量得到了显著提高,得到了消费者的认可和好评。

纺织品质检是确保纺织品质量的重要环节,通过严格的质量检测,可以确保纺织品符合相关标准和法规,保障人们的穿着安全和健康,通过质检还可以提高纺织品的市场竞争力,促进纺织行业的发展,在纺织品质检中,我们应该注重样品采集、检测指标的选择、数据记录与分析等方面的工作,以确保检测结果的准确性和可靠性,我们还应该加强与供应商的合作,确保原材料的质量符合要求,我们建议大家在购买纺织品时,选择有质量保证的品牌和厂家,以确保产品的质量和安全性。

Articles related to the knowledge points of this article:

The Dynamic World of Woollen Apparel:An Overview with a Twist