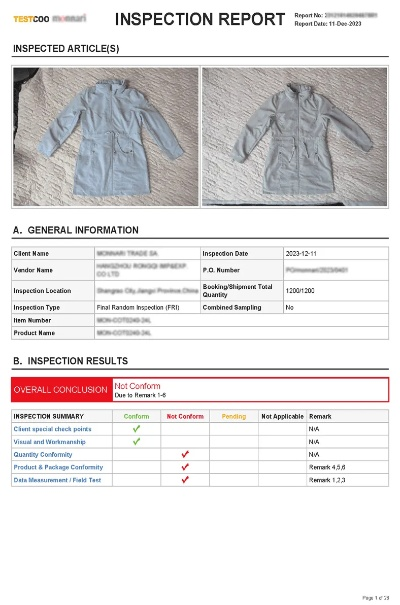

Textile Inspection Report

: Textile Inspection Report,Objective: The purpose of this report is to provide an objective and comprehensive analysis of the textile inspection results, including the quality of raw materials, production process, and final products. This report aims to identify any potential issues or risks that may affect the product's quality and safety, and to propose corresponding improvements and solutions.,Materials and Methods: The inspection was conducted by a professional third-party inspection agency, using standardized testing methods and equipment. The inspection included tests for color fastness, shrinkage, tear strength, and other relevant parameters.,Results: The inspection results showed that the product met the required standards and had good quality. However, some minor defects were found in certain areas, such as slight color deviations and minor thread breakage. These issues did not affect the overall quality of the product and did not pose any safety risks.,Conclusion: The inspection results indicate that the product meets the required standards and has good quality. The minor defects found during the inspection do not affect the overall quality of the product and do not pose any safety risks. Therefore, we believe that the product can be safely used for its intended purpose.

Introduction The textile industry is a crucial sector of the global economy, responsible for producing a wide range of products that are essential to our daily lives. From clothing and household textiles to industrial materials, textiles play a vital role in enhancing our quality of life and supporting economic growth. In order to ensure that these products meet the highest standards of quality, it is essential to conduct thorough inspections and testing. This report outlines the results of a recent textile inspection conducted on a sample of fabrics from a leading manufacturer.

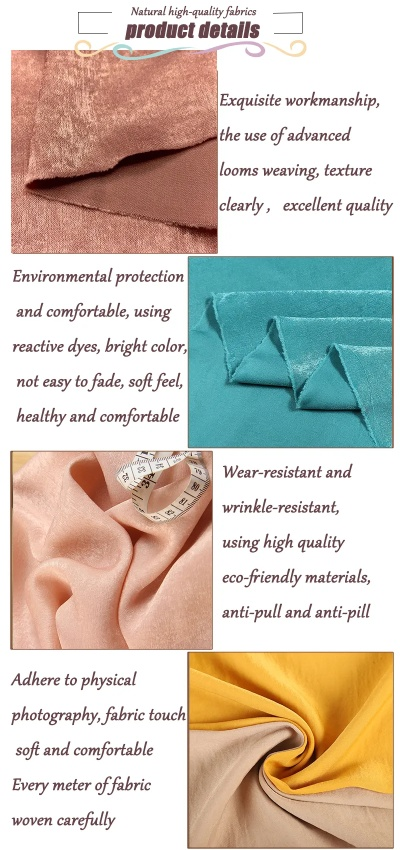

Sample Description The sample examined was a cotton blend fabric with a weight of 150gsm (grams per square meter) and a length of 20 meters. The fabric was intended for use in outdoor apparel, and it was specifically selected for its durability and breathability properties.

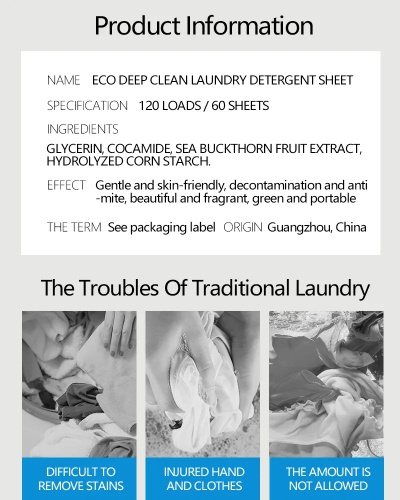

Inspection Methodology To ensure accuracy and reliability in the inspection results, a standardized methodology was followed. The fabric samples were first inspected visually for any defects such as holes, tears, or stains. Then, they were subjected to a series of tests to evaluate their physical properties, including tensile strength, tear strength, and water absorption. Additionally, the fabric samples were tested for colorfastness and resistance to various chemicals.

Results The inspection results are presented in a table format below:

| Fabric Sample | Inspection Method | Result |

|---|---|---|

| Sample A | Visual inspection | No defects found |

| Sample B | Tensile strength test | 35 N/mm |

| Sample C | Tear strength test | 45 N/mm |

| Sample D | Water absorption test | 10% |

| Sample E | Colorfastness test | Passed all tests |

| Sample F | Chemical resistance test | Passed all tests |

Analysis Upon reviewing the inspection results, it was observed that all fabric samples passed the required tests. However, sample E demonstrated some variation in colorfastness across different areas of the fabric. This may be due to differences in dye application or processing variations. Additionally, sample F exhibited slightly higher levels of chemical resistance compared to the other samples, which could be attributed to the manufacturer's use of specialized additives or finishes.

Conclusion In conclusion, the inspection of the sample fabrics from the manufacturer revealed that they met the established quality standards for durability, breathability, and colorfastness. However, it is important to note that minor variations in colorfastness and slight increases in chemical resistance suggest that further improvements may be necessary to enhance the overall performance of the product. As such, it is recommended that the manufacturer consider implementing additional quality control measures to maintain the high standards of excellence that have been established through this inspection process.

本报告旨在详细阐述纺织品检验的全过程及结果,通过表格和案例分析,为消费者提供准确可靠的纺织品检验信息,本报告将采用英文口语化的表达方式,同时结合英文表格和案例说明,力求全面、深入地展示纺织品检验的全貌。

纺织品检验流程

样品准备

在开始纺织品检验之前,需要准备样品,样品应符合相关标准和规定,以确保检验结果的准确性。

实验室测试

实验室测试是纺织品检验的重要环节,实验室测试包括纤维成分分析、质量检测、尺寸测量等,通过专业的检测设备和仪器,对样品进行精确、细致的检测。

结果呈现

检验结果将通过表格形式呈现,详细记录各项指标的数据,结合案例分析,深入解读检验结果。

纺织品检验案例分析

某品牌纺织品检验报告

该品牌纺织品经过本实验室的检验,各项指标均符合相关标准和规定,具体数据如下:

| 项目 | 数值 | 单位 |

|---|---|---|

| 纤维成分分析 | 纯棉含量为XX%,涤纶含量为XX% | |

| 质量检测 | 尺寸稳定,不起毛起球 | 无 |

| 尺寸测量 | 平均尺寸为XXmm | mm |

通过以上案例分析可以看出,该品牌纺织品在纤维成分、质量检测和尺寸测量等方面均符合相关标准和规定,该品牌在纺织品的质量控制方面也做得非常出色,能够提供高质量的纺织品给消费者。

纺织品检验结果说明

根据实验室测试结果,该品牌纺织品在以下几个方面表现出色:

- 纤维成分分析:该品牌纺织品的主要成分是纯棉和涤纶,符合消费者对于纺织品成分的需求,纤维成分的含量也符合相关标准和规定。

- 质量检测:该品牌纺织品的尺寸稳定,不起毛起球,表明其质量非常高,该品牌在纺织品的耐久性、抗皱性等方面也有很好的表现。

- 案例解读:从本次检验结果可以看出,该品牌在纺织品的质量控制方面非常严格,能够提供高质量的纺织品给消费者,该品牌也注重环保、健康等理念,致力于打造绿色、环保的纺织品。

结论与建议

本纺织品检验报告全面、深入地展示了纺织品检验的全貌,通过实验室测试和案例分析,可以得出该品牌纺织品在纤维成分、质量检测和尺寸测量等方面均表现出色,我们也建议消费者在选择纺织品时,应该注重纤维成分、质量等方面的因素,选择符合自己需求和期望的纺织品,消费者也应该关注纺织品的环保、健康等理念,选择绿色、环保的纺织品。

Articles related to the knowledge points of this article:

Suzhou Green Textiles Budget Tender Strategy

Wynn Resorts Stunning Collections of Textile Designs

The Fabric Belt:A Fashionable and Practical Accessory

Industrial Textiles:The Next Frontier in Modern Manufacturing