A Comprehensive Guide to Textile Analysis Testing

This comprehensive guide to textile analysis testing provides a detailed overview of the various methods and techniques used in the industry for evaluating the quality and performance of textile materials. The guide covers topics such as colorimetry, tensile testing, tearing tests, flame resistance, and water absorption. Each section includes explanations of the testing procedures, sample preparation, and data interpretation. Additionally, the guide provides practical examples of how to use these tests to identify potential issues with textile products and recommend appropriate solutions. Overall, this guide is an essential resource for anyone working in the textile industry who wants to ensure that their products meet stringent standards and meet the needs of their customers.

Introduction: Textile analysis testing is an essential aspect of the textile industry, as it helps in ensuring the quality, consistency, and safety of products made from fabrics. In this guide, we will explore various types of textile analysis tests that are commonly used in the industry. We will also provide some examples of how these tests can be applied in real-world scenarios.

Types of Textile Analysis Tests:

-

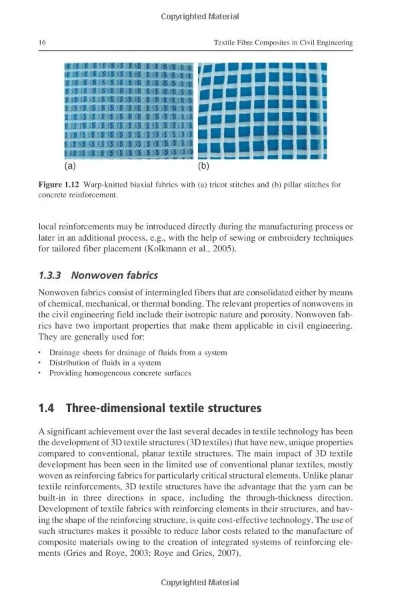

Structural Analysis: This type of test involves examining the physical properties of a textile material, such as its strength, flexibility, and durability. Examples of structural analysis tests include tensile testing, compression testing, and tear testing.

-

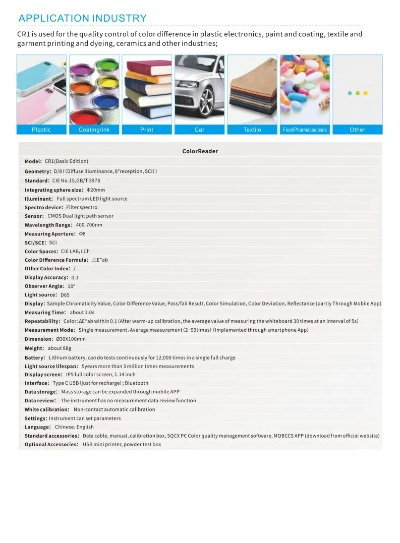

Chemical Analysis: This type of test involves analyzing the chemical composition of a textile material, including its fibers, yarns, and fabrics. Examples of chemical analysis tests include elemental analysis, chromatography, and spectrophotometry.

-

Physical Analysis: This type of test involves measuring the physical properties of a textile material, such as its weight, thickness, and density. Examples of physical analysis tests include weight measurement, thickness measurement, and density measurement.

-

Environmental Analysis: This type of test involves assessing the environmental impact of a textile material, such as its toxicity, biodegradability, and water absorption. Examples of environmental analysis tests include toxicity testing, biodegradability testing, and water absorption testing.

-

Functional Analysis: This type of test involves evaluating the performance of a textile material in specific applications, such as clothing or sportswear. Examples of functional analysis tests include wearability testing, comfort testing, and performance testing.

Examples:

-

Tensile Testing: This test is used to measure the strength and elasticity of a textile material under tension. For example, a sample of a cotton shirt would undergo tensile testing to determine its breaking strength and elongation.

-

Compression Testing: This test is used to measure the resistance of a textile material to being compressed. For example, a sample of a polyester jacket would undergo compression testing to determine its burst strength and dimensional stability.

-

Tear Testing: This test is used to measure the resistance of a textile material to being torn apart. For example, a sample of a denim jeans would undergo tear testing to determine its tear strength and tear resistance.

-

Toxicity Testing: This test is used to evaluate the potential health risks associated with a textile material. For example, a sample of a synthetic fabric could undergo toxicity testing to determine if it contains harmful chemicals that could cause skin irritation or respiratory problems.

-

Biodegradability Testing: This test is used to evaluate the ability of a textile material to decompose naturally into harmless substances. For example, a sample of a organic cotton t-shirt could undergo biodegradability testing to determine if it can break down into natural materials without releasing harmful pollutants into the environment.

Conclusion: Textile analysis testing is an essential tool for ensuring the quality and safety of textile products. By understanding the different types of tests available and their applications, we can better understand the performance of our textile materials and make informed decisions about their use.

纺织品分析测试概述

纺织品分析测试是评估纺织品质量、性能和安全的重要手段,它涵盖了多种测试方法,包括但不限于物理性能测试、化学分析测试、微生物测试、纤维成分分析等,以下是关于纺织品分析测试的一些主要内容和相关案例。

主要纺织品分析测试方法

物理性能测试

(1)拉伸性能测试:用于评估纤维的拉伸强度、弹性模量和断裂伸长率等。

案例:某品牌牛仔布的拉伸性能测试,通过不同拉伸倍数下的断裂伸长率来评估其耐磨性和抗皱性。

(2)密度测试:用于测量纤维的密度,用于评估纤维的厚度和重量。

案例:某新型面料采用高密度技术,通过密度测试来评估其保暖性能和舒适度。

化学分析测试

(1)成分分析:用于检测纤维的主要成分,如纤维类型、含量等。

案例:某品牌丝绸面料成分分析,通过化学分析测试来了解其原料来源和质量。

(2)耐久性测试:用于评估纤维在特定环境条件下的耐久性,如洗涤、干燥等。

案例:某新型防水面料经过耐久性测试,证明其在恶劣环境下的防水性能和稳定性。

微生物测试

(1)细菌检测:用于检测纺织品中是否存在有害微生物,如细菌、真菌等。

案例:某品牌床上用品进行微生物检测,确保产品安全无害。

(2)真菌培养与鉴定:用于评估纺织品中真菌的生长情况和种类,为纺织品质量提供参考依据。

纤维成分分析

(1)纤维类型鉴定:通过显微镜观察纤维的形态和结构,确定纤维类型。

案例:某品牌服装采用特定纤维类型制作,通过纤维类型鉴定来满足特定需求。

(2)纤维含量测定:通过化学分析方法测定纤维的含量,评估纤维的质量和性能。

案例说明

以纺织品为例,具体说明不同分析测试方法的应用,某品牌的一款新型面料采用了高科技纤维技术,通过物理性能测试和化学分析测试来评估其性能和质量,在物理性能测试中,该面料表现出了良好的拉伸性能和密度,满足了产品的特定需求,在化学分析测试中,该面料的主要成分是高品质的聚酯纤维,含量较高,满足了产品的安全和质量要求,该面料还进行了微生物测试和纤维成分分析,确保产品的安全性和可靠性。

纺织品分析测试是评估纺织品质量、性能和安全的重要手段,不同的纺织品需要采用不同的分析测试方法,以满足特定的需求和标准,随着科技的发展,纺织品分析测试方法也在不断更新和完善,为纺织品的质量和安全提供了更加可靠的保障。

Articles related to the knowledge points of this article:

Textile Options in the纺织品用哪个字代替

Revolutionizing Textiles:The Future of Material Innovation