Understanding the Textile Color Stain Levels:A Guide for Quality Control

"Understanding the Textile Color Stain Levels: A Guide for Quality Control" provides a comprehensive overview of the various levels of textile color stains and their implications on product quality. The guide highlights the importance of identifying these stains early in the production process, as they can significantly impact the final product's appearance and consumer perception.,The text discusses the different types of textile stains, including dye transfer, oil-based stains, and water-based stains, each with its unique characteristics and challenges. It also provides insights into the causes of these stains, such as improper dye application or processing errors, and how to prevent them through proper procedures and equipment maintenance.,Furthermore, the guide emphasizes the importance of regular inspections and testing during the production process to detect and correct any issues before they reach the end user. It recommends using advanced detection technologies and analytical tools to accurately identify and quantify the level of color stains, enabling manufacturers to make informed decisions about product quality control.,Overall, "Understanding the Textile Color Stain Levels: A Guide for Quality Control" is a valuable resource for textile manufacturers seeking to improve their product quality and customer satisfaction. By following this guide, manufacturers can effectively manage and control the levels of color stains in their products, ensuring that their products meet the highest standards of quality and reliability."

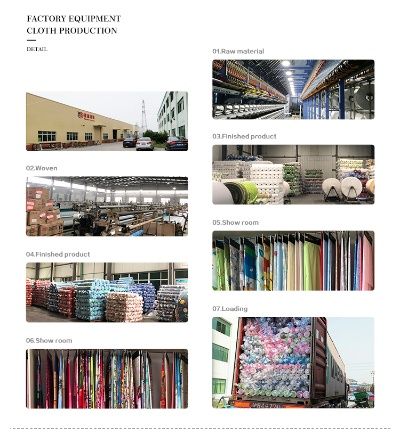

Introduction: In the world of textile manufacturing, color is often the most important aspect that determines the overall quality and appeal of a product. The ability to control color uniformity and prevent stains from affecting the final product is crucial for manufacturers to meet consumer expectations and maintain brand integrity. This article will provide an overview of textile color stain levels and how they are determined, along with practical examples to illustrate their importance in the textile industry.

Textile Color Stain Levels: The term "textile color stain level" refers to the degree to which a fabric has been stained or discolored during the dyeing process. There are different types of stains that can occur during the dyeing process, including primary, secondary, and tertiary stains. Each type of stain affects the color of the fabric differently, and understanding their characteristics is essential for effective color control.

Primary stains are those that occur during the dyeing process itself, such as bleeding or bleeding-off. These stains are typically more difficult to remove than secondary or tertiary stains, but they can be managed by using specialized dyes or pretreatment techniques.

Secondary stains are caused by the interaction between the dye and the fibers during the dyeing process. They can affect both the color and the texture of the fabric. Secondary stains are more likely to occur in areas where the fibers are not fully penetrated by the dye, such as the edges or seams.

Tertiary stains are those that develop after the fabric has been washed or dried. They can be caused by environmental factors such as sunlight or airborne pollutants, or by chemical reactions between the fabric and other materials. Tertiary stains are generally more difficult to remove than primary or secondary stains, but some methods can be used to minimize their impact.

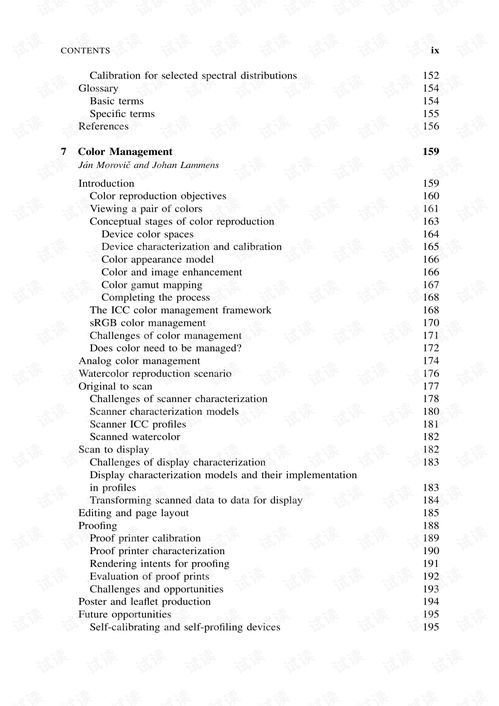

Determining Textile Color Stain Levels: To determine the color stain level of a fabric, manufacturers typically use a combination of visual inspection and laboratory testing. Visual inspection involves examining the fabric under a microscope to identify any visible stains or discolorations. This method is useful for identifying primary stains, which are more easily visible than secondary or tertiary stains.

Laboratory testing involves analyzing the fabric's dye content and color properties using spectrophotometry and other analytical methods. This allows manufacturers to determine the level of stains present in the fabric and to optimize dyeing processes for maximum color control.

Practical Example: One common example of textile color stain levels is the case of a garment manufacturer who produces shirts with a bright red color. During the dyeing process, primary stains may occur due to bleeding-off, causing some of the red color to spread onto adjacent areas of the fabric. To manage this issue, the manufacturer could use a specialized dye that is less prone to bleeding-off, or pretreat the fabric with a bleaching agent to reduce the amount of primary stains.

Another example is a textile company that produces linens with a natural white color. During the dyeing process, secondary stains may develop due to the interaction between the dye and the fibers. To minimize these stains, the manufacturer could use a pretreatment technique that enhances the fiber's natural whiteness, or adjust the dye formulation to better penetrate the fibers and reduce secondary stains.

Conclusion: Understanding textile color stain levels is crucial for maintaining the quality and appearance of finished products. By employing proper dyeing processes and implementing effective color control measures, manufacturers can produce textiles that meet consumer expectations and stand out in the competitive market. With the right knowledge and tools, even the most challenging stains can be mitigated, allowing textile manufacturers to deliver high-quality products that exceed customer satisfaction.

纺织品沾色等级概述

纺织品沾色等级是衡量纺织品在使用过程中受到污染程度的重要指标,根据不同的标准和方法,可以将纺织品沾色等级分为不同的级别,以便更好地了解其耐久性和使用性能,以下是纺织品沾色等级的基本概念和分类。

沾色等级分类及说明

轻微沾色等级

轻微沾色等级的纺织品通常指在使用过程中出现轻微染色现象,不影响其基本使用功能和外观,这类纺织品通常适用于日常穿着和家居装饰。

中度沾色等级

中度沾色等级的纺织品在使用过程中可能出现中度染色现象,但不影响其基本使用性能和外观,这类纺织品适用于特定场合,如工作服、运动服等。

重度沾色等级

重度沾色等级的纺织品在使用过程中染色现象较为严重,严重影响其使用性能和外观,这类纺织品通常需要特殊的清洗和处理措施,以确保其耐久性和使用效果。

沾色等级案例分析

某品牌丝绸面料沾色等级分析

该品牌丝绸面料在使用过程中可能出现轻微染色现象,但其基本使用功能和外观不受影响,该丝绸面料属于轻微沾色等级,该品牌的丝绸面料采用天然纤维制作,具有柔软、光滑、光泽度好的特点,适合日常穿着和家居装饰。

某运动品牌运动服沾色等级分析

某运动品牌运动服在使用过程中可能出现中度染色现象,但不影响其耐久性和使用效果,该品牌注重运动服装的舒适性和功能性,采用高品质面料和工艺制作,确保运动服装在运动过程中保持良好的性能和外观,该运动品牌运动服属于中度沾色等级。

沾色等级检测方法及标准

-

检测方法:采用目测、仪器检测等方法对纺织品沾色等级进行评估,目测法适用于轻微沾色等级的评估,仪器检测法适用于中度沾色等级和重度沾色等级的评估。

-

标准:根据不同的纺织品类型和用途,制定相应的沾色等级标准,丝绸面料的标准可能包括颜色均匀度、染色深度等指标;运动服装的标准可能包括耐久性、抗污性等指标。

提高纺织品沾色等级的措施

-

选用优质面料:选择优质面料是提高纺织品沾色等级的关键措施,优质面料具有更好的耐久性和使用性能,能够更好地抵抗染色现象。

-

注意使用环境:在使用纺织品时,要注意避免接触化学物质、油污等污染源,以减少染色现象的发生。

-

定期清洗和维护:定期清洗和维护纺织品是保持其耐久性和使用性能的重要措施,清洗时应选用合适的清洗剂和清洗方法,避免过度清洗或不当处理导致染色现象加剧。

纺织品沾色等级是衡量纺织品耐久性和使用性能的重要指标,根据不同的标准和方法,可以将纺织品沾色等级分为轻微沾色等级、中度沾色等级和重度沾色等级,在实际应用中,我们应选用优质面料、注意使用环境、定期清洗和维护纺织品,以提高其耐久性和使用性能,我们也应关注沾色等级检测方法及标准的发展,以便更好地了解纺织品的使用性能和外观质量。

Articles related to the knowledge points of this article:

Guangdong Textile Inspection:A Comprehensive Review