The Fabrication of Quality:A Tale of Textile Mill Spinning Workers

: The Fabrication of Quality: A Tale of Textile Mill Spinning Workers,Abstract:,This article delves into the life and work of textile mill spinning workers, highlighting their commitment to producing high-quality textiles. Through interviews with these workers, we explore their daily routines, challenges faced in the industry, and their efforts towards maintaining and enhancing the quality of textiles. The article underscores the significance of these workers' contributions to the fabrication of quality in the textile industry and their role in preserving the value and aesthetic appeal of textile products.

Introduction: In the vast world of textile manufacturing, the role of the spinner is one that demands precision and dedication. At a textile mill, the spinning process is where fibers are transformed into yarn, the building block of fabric. But what does it take to master this craft? How do these workers ensure their products meet the highest standards? Let's dive into the life of a textile mill spinner and explore the challenges they face, as well as the triumphs they achieve in their daily endeavors.

Textile Mill Spinning Workers: Their Role and Responsibilities Spinning workers at textile mills are the backbone of the industry. They work tirelessly to produce high-quality yarns that meet the needs of various industries and markets. These skilled individuals are responsible for several key tasks:

-

Preparing Fibers: Before spinning, the raw materials (such as cotton, wool, or synthetic fibers) must be cleaned, carded, and spun into thread. This initial phase involves significant manual labor and often requires specialized equipment.

-

Spinning: Once the fibers are prepared, they are then spun into yarn using a machine called a spindle. This process involves twisting the fibers together, creating a continuous filament. The spinner controls the speed and tension of the spindle to achieve the desired yarn quality.

-

Yarn Testing: After spinning, each batch of yarn undergoes rigorous testing to ensure it meets specific standards. This includes measuring its thickness, strength, and evenness.

-

Packaging: Finally, the yarn is packaged and sent off to factories or directly to end users. The packaging process also plays a crucial role in protecting the yarn during transportation.

Challenges Faced by Textile Mill Spinning Workers Despite their hard work, spinners face several challenges that can impact their productivity and quality of work:

-

Physical Labor: Spinning is a physically demanding job that requires long hours on machinery. It can lead to injuries and health issues if not properly managed.

-

High Demand: With global demand for textiles constantly fluctuating, spinners often work overtime and may need to adjust their schedules accordingly.

-

Changing Markets: The textile market is highly competitive, with new technologies and trends emerging regularly. Spinners must stay up-to-date with these changes to maintain their skills and remain relevant in the industry.

-

Environmental Pressures: As concerns about sustainability grow, spinners must balance their production methods with environmental considerations, such as reducing waste and using sustainable materials.

Case Study: The Success Story of a Textile Mill Spinning Worker Let's turn our attention to the success story of an individual who has made a name for himself as a textile mill spinner. John, a seasoned worker with years of experience in the industry, has developed a unique approach to his craft that has earned him recognition both within his team and beyond.

John's journey began at a small mill where he learned the basics of spinning from scratch. Over time, he honed his skills and became adept at managing the complex machinery used in the process. He quickly recognized that his expertise could be leveraged to improve the overall efficiency and quality of the mill's output.

One day, John noticed a pattern in the yarn produced by his team that suggested potential defects. Instead of dismissing it outright, he took the time to analyze the issue and devised a solution. By implementing his innovative ideas, he was able to reduce waste and increase the consistency of the yarn's properties.

John's efforts were not only beneficial to his team but also contributed to the overall success of the mill. His commitment to excellence and willingness to take risks have earned him a reputation as a leader within the industry. Today, John is considered a respected figure in the textile sector, having founded his own company specializing in high-quality yarn production.

Conclusion: The textile mill spinner's journey is a testament to the importance of hard work, dedication, and innovation. Through their daily routines, these workers not only create the fabric we wear but also pave the way for future generations of textile engineers. As we continue to witness the evolution of the textile industry, it is essential that we recognize the contributions of those like John and other spinning experts who keep this vital trade alive.

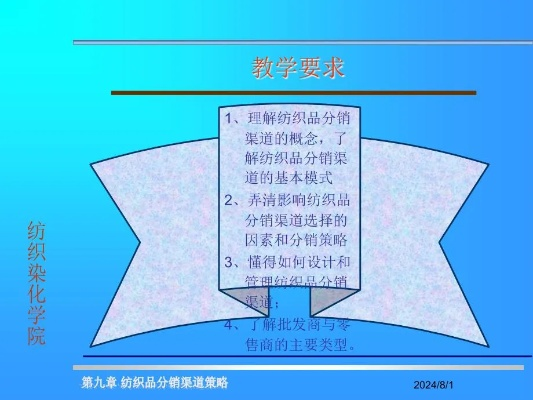

纺织厂纺丝工简介

在纺织厂中,纺丝工是负责将纤维原料加工成纱线的重要岗位,他们的工作不仅涉及到纺织技术的精湛应用,还与生产效率和产品质量息息相关,下面我们将从工作内容、技能要求、工作环境等方面对纺织厂纺丝工进行详细介绍。

- 原料准备:纺丝工需要熟悉各种纤维原料的特性,根据生产需求选择合适的原料进行纺丝。

- 纺丝操作:在纺丝机前,纺丝工需要按照工艺要求操作纺丝机,确保纱线的质量。

- 产品检验:在生产过程中,纺丝工还需要对产品进行严格的质量检验,确保符合质量标准。

技能要求

- 熟练掌握纺织技术:纺丝工需要掌握纺织纤维的加工工艺,包括纤维的纺丝、织造、染整等。

- 良好的操作技能:纺丝工需要具备熟练的操作技能,能够准确、高效地完成纺丝工作。

- 良好的团队协作能力:纺丝工需要与同事紧密合作,共同完成生产任务。

工作环境

- 高强度的工作压力:纺织厂的工作环境通常较为艰苦,需要承受高强度的工作压力。

- 高温高湿环境:纺织厂通常处于高温高湿的环境中,这对员工的身体健康和工作环境都有一定的影响。

- 设备齐全:纺织厂需要配备先进的纺丝设备和生产线,以确保生产效率和产品质量。

案例说明

以一家知名的纺织厂为例,介绍纺丝工的工作环境和具体工作内容。

某纺织厂纺丝工的工作环境与工作内容

该纺织厂拥有先进的纺丝设备和生产线,员工们每天都在紧张而有序地进行工作,纺丝工们需要在高温高湿的环境下,熟练地操作纺丝机,确保纱线的质量,他们需要仔细检查每一根纱线,确保产品符合质量标准,他们还需要与同事紧密合作,共同完成生产任务。

英文表格补充说明

以下是英文表格,用于进一步说明纺织厂纺丝工的相关信息:

纺织厂纺丝工信息表

| 岗位名称 | 技能要求 | 工作环境 | 设备与生产线情况 | 案例描述 | |

|---|---|---|---|---|---|

| 纺丝工 | 原料准备、纺丝操作、产品检验 | 熟练掌握纺织技术、良好的操作技能、团队协作能力 | 高强度的工作压力、高温高湿环境、设备齐全 | 该纺织厂拥有先进的设备和生产线,员工们每天都在紧张而有序地进行工作 | 以某知名纺织厂为例,介绍其工作环境和具体工作内容 |

纺织厂纺丝工是纺织生产过程中的重要岗位,他们的工作不仅关系到产品的质量和产量,还关系到员工的身体健康和生产效率,对于纺织厂来说,需要重视对纺丝工的培养和管理,提高他们的技能水平和综合素质,也需要为纺丝工提供良好的工作环境和福利待遇,以激发他们的积极性和创造力。

Articles related to the knowledge points of this article:

The 22-Year-Old Textile Factory:A Journey Through Youth and Potential

The Art of Textile Factory Plastic Belt Making

The Story of the Spinning Silk in Prosperous Pang Shan Linhong Textile Factory