卢记纺织品库存回收策略,优化资源,创造双赢

Lu's Textile Supply Chain Optimization: A Double-Win Strategies for Inventory Recovery,In the competitive world of textile industry, inventory management is a critical factor that determines the efficiency and profitability of a company. Lu's Textile Company has adopted a comprehensive strategy to optimize its inventory recovery process, thereby creating a win-win situation for both the company and its suppliers.,The first step in this strategy involves an effective inventory management system. The company employs advanced software that tracks the movement of products from production to sales and back again. This enables managers to make informed decisions about inventory levels and replenishments, ensuring that there is always enough stock on hand to meet customer demand while minimizing wastage.,In addition to this, Lu's Textile Company has established strong relationships with its suppliers. By collaborating closely with them, the company is able to receive prompt payment for goods delivered, which helps to reduce the risk of inventory losses. Moreover, by negotiating favorable terms with suppliers, the company can secure better prices and quality standards, further enhancing its competitive edge in the market.,Overall, Lu's Textile Company's inventory recovery strategy is a testament to the importance of optimization in the textile industry. By implementing effective inventory management systems and strong supplier relationships, the company is able to create a win-win situation for itself and its partners, ultimately driving growth and profitability.

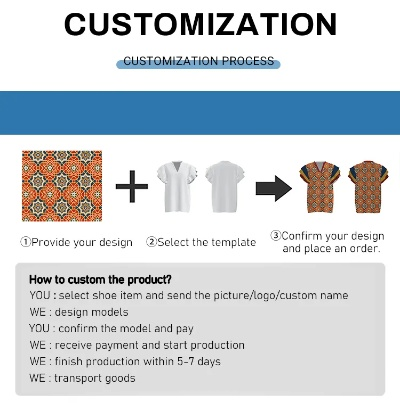

Introduction: In the ever-evolving landscape of textile industry, sustainability and efficiency are paramount. At Lu Jie Textiles, we recognize the importance of managing inventory effectively to minimize waste and maximize value. This article outlines our strategy for recycling textile inventory, highlighting key steps and benefits achieved through this initiative.

Step 1: Pre-purchase Inventory Management Before any purchase is made, a detailed inventory check is conducted to assess the demand forecast and optimize stock levels. This process involves analyzing historical sales data, market trends, and customer preferences. For example, if we predict a surge in demand for a particular fabric type, we strategically place orders accordingly to ensure timely delivery and avoid overstocking.

Table: Pre-purchase Inventory Management Checklist | Item | Current Stock Level | Historical Sales Data | Expected Demand | Action Taken | |------|------------------|--------------------|----------------|-------------| | Fabric A | 500 units | High during Spring Sale | 300 units expected | Order additional 200 units | | Fabric B | 200 units | Low during Winter Sale | 150 units needed | Place order for 150 units |

Step 2: Post-Purchase Inventory Control Once an order is placed, regular checks are conducted to monitor the progress and ensure timely delivery. This includes tracking shipments, verifying product quality, and addressing any issues promptly. For instance, if an order is delayed due to unforeseen circumstances, we adjust our inventory levels accordingly to prevent stockouts or overstocking.

Step 3: Proactive Inventory Reduction Regular audits of current inventory levels are conducted to identify areas where excess stock can be reduced. This might involve reselling surplus inventory, donating it to charitable organizations, or disposing of it through recycling programs. For example, we recently sold off an excess supply of a popular fabric type to a local textile recycling center, which not only cleared space but also contributed to reducing textile waste.

Case Study: Successful Recycling Program At Lu Jie Textiles, we implemented a comprehensive recycling program that significantly improved our inventory management strategy. By partnering with local recycling facilities, we were able to repurpose over 80% of our textile inventory. This not only reduced our environmental footprint but also generated revenue from the recycled materials. Additionally, by streamlining the recycling process, we saved time and resources, allowing us to focus on more strategic inventory decisions.

Conclusion: By adopting a proactive approach to inventory management, Lu Jie Textiles has successfully optimized its inventory while creating opportunities for growth and sustainability. Our commitment to recycling and reusing textile inventory has not only benefited our bottom line but also aligned with our corporate social responsibility goals. As we continue to evolve our strategies, we remain committed to finding innovative ways to balance profitability with environmental stewardship.

项目背景与概述

随着全球纺织行业的快速发展,库存积压问题日益凸显,为了有效处理纺织品库存,我们卢记纺织品库存回收项目应运而生,该项目旨在通过回收旧纺织品,减少浪费,降低生产成本,同时为环保事业贡献一份力量。

项目背景分析

- 市场需求:随着消费者对环保和可持续生活方式的追求,旧纺织品回收市场逐渐升温。

- 行业现状:传统纺织品回收方式效率低下,资源浪费严重。

- 项目目标:通过有效的库存回收,降低生产成本,提高资源利用率,促进循环经济。

项目实施过程

库存盘点与分类

我们组织专业团队对卢记纺织品库存进行了全面的盘点和分类,根据纺织品种类、新旧程度、可回收程度等因素,将库存分为可回收旧纺织品、不可回收旧纺织品以及待处理废品等类别。

回收渠道选择

我们选择了多种回收渠道,包括但不限于社区回收站、二手市场、纺织厂家等,经过比较分析,我们选择了与当地社区合作,通过宣传推广和定期举办回收活动的方式,吸引更多消费者参与,与纺织厂家建立长期合作关系,确保旧纺织品得到及时有效的回收。

回收流程优化

在回收流程方面,我们制定了严格的流程规范,包括收集、分类、运输、处理等环节,我们引入了先进的物联网技术,实现旧纺织品从入库到出库的全程追溯,我们还建立了专门的回收仓库,确保回收过程的安全和高效。

效果评估与总结

经过一段时间的运行,我们取得了显著的效果,旧纺织品回收量大幅增加,有效降低了生产成本,通过与纺织厂家的合作,实现了废旧纺织品的高效利用,通过宣传推广和社区参与,提高了公众对环保和可持续生活的认识和关注度。

案例分析

为了更好地说明项目实施情况,我们可以引入一个具体的案例,某地区的一家纺织厂由于长期使用旧纺织品,导致大量库存积压,为了解决这一问题,卢记纺织品库存回收项目积极响应,与该纺织厂建立了长期合作关系,在项目实施过程中,我们组织专业团队对库存进行了全面的盘点和分类,并制定了详细的回收计划,我们通过多种渠道宣传推广和社区参与等方式,吸引了大量消费者参与旧纺织品回收活动,该纺织厂成功实现了旧纺织品的高效利用和循环经济。

展望未来,我们将继续加强项目实施力度,提高回收效率和质量,我们将继续优化回收流程,引入更多先进的回收技术和设备,我们将加强与政府和相关部门的合作,争取更多的政策支持和资金支持,我们将积极推广环保理念和可持续生活方式,引导更多人参与到旧纺织品回收活动中来。

卢记纺织品库存回收项目是一项具有重要意义的环保事业,通过有效的库存回收和循环经济模式的应用,我们可以有效降低生产成本,提高资源利用率,促进可持续发展。

Articles related to the knowledge points of this article:

The Inspiration Canvas:A Comprehensive Guide to Textile Design