Textiles Thermo-Infrared Testing Methodology

This paper presents a novel methodology for the thermo-infrared testing of textiles. The technique involves the application of infrared radiation to the fabric surface and the subsequent measurement of the transmitted spectrum, which can provide insights into the thermal properties of the material. The methodology is particularly useful for assessing the thermal conductivity, thermal diffusivity, and thermal resistance of textiles, as well as for monitoring changes in these properties over time due to various factors such as wear and aging.,The paper also discusses the advantages and limitations of the thermo-infrared testing method, including its ability to provide non-destructive and in-situ measurements, as well as its sensitivity to changes in material composition and structure. Additionally, the paper provides an overview of the experimental setup and data analysis procedures used in the study, as well as a comparison of the results obtained with other commonly used methods for measuring thermal properties of textiles. Overall, the paper demonstrates the potential of thermo-infrared testing as a valuable tool for characterizing the thermal behavior of textile materials.

Introduction to Textiles Thermo-Infrared Testing

Textiles, as a crucial component of our daily lives, play an essential role in providing warmth and comfort. The quality of these materials is often determined by their ability to absorb and release heat efficiently. One of the most effective ways to assess this property is through thermo-infrared testing, which involves measuring the thermal radiation emitted from textile samples. In this article, we will explore the intricacies of thermo-infrared testing for textiles and provide an overview of the methodologies used in practice.

Thermal Radiation Principles

Before delving into the details of thermo-infrared testing, it is essential to understand the underlying principles behind thermal radiation. When matter interacts with another object, it can transfer energy in the form of light or heat. This process is known as infrared radiation, and it is responsible for the sensation of warmth we experience when we touch something warm.

Textiles are composed of various materials, including synthetic fibers, natural fibers, and blends thereof. Each material has unique properties that affect its ability to absorb and emit thermal radiation. For example, synthetic fibers like polyester and nylon tend to have lower thermal conductivity than natural fibers like cotton and wool, which means they absorb fewer calories during heating and cooling processes.

Thermo-Infrared Testing Techniques

To measure the thermal radiation emitted from textile samples, several techniques are employed. These include:

-

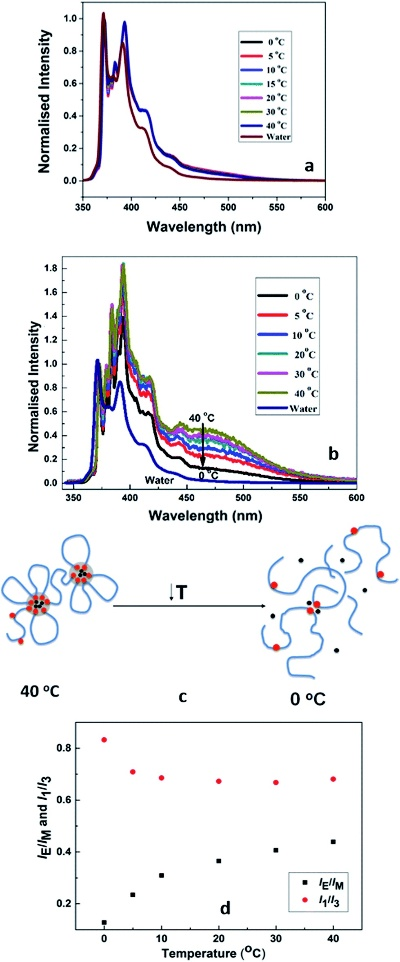

Spectral Analysis: This technique involves analyzing the infrared spectrum of the sample to identify specific wavelengths that correspond to different functional groups within the textile material. By comparing the spectral data with known standards, researchers can determine the type and concentration of these functional groups.

-

Transmittance Testing: This method measures the amount of infrared radiation transmitted through a fabric sample. It is commonly used to evaluate the thermal conductivity of textiles, as higher transmittance values indicate better thermal performance.

-

Absorption Testing: This technique involves measuring the amount of infrared radiation absorbed by a fabric sample. It is useful for evaluating the thermal absorptivity of textiles, as higher absorption values suggest better thermal insulation.

-

Differential Scanning Calorimetry (DSC): This technique uses a differential scanning calorimeter to heat a sample at a controlled rate and measure the resulting change in heat content. DSC is widely used in the textile industry for determining the thermal properties of materials such as yarns and fabrics.

Application of Thermo-Infrared Testing in Textiles

Thermo-infrared testing has numerous applications in the textile industry, including:

-

Quality Control: Regular inspection of textile products using thermo-infrared testing helps manufacturers ensure that their products meet regulatory standards and customer expectations.

-

Product Development: Researchers and engineers use thermo-infrared testing to optimize the design of new textile materials, ensuring they meet the desired thermal performance requirements.

-

Environmental Assessment: Textile companies can use thermo-infrared testing to assess the environmental impact of their products, particularly in areas where energy efficiency is a concern.

-

Energy Efficiency: Thermo-infrared testing can be used to evaluate the thermal performance of building materials such as curtain walls and insulation systems, helping to improve energy efficiency and reduce energy costs.

Case Study: Thermo-Infrared Testing in a New Fashion Trend

Recently, a leading fashion brand launched a new line of thermally efficient clothing made from recycled materials. To ensure that their products met the highest standards of thermal performance, the company conducted a comprehensive thermo-infrared testing program. They tested various fabrics, including organic cotton, bamboo, and recycled polyester, using both transmittance and absorption tests.

The results showed that the recycled polyester fabric had significantly improved thermal conductivity compared to traditional fabrics, making it an ideal choice for creating high-performance clothing. The company also discovered that incorporating bamboo fibers into their fabrics increased the overall thermal absorptivity, further enhancing the garment's thermal performance.

Conclusion

Thermo-infrared testing is a powerful tool for assessing the thermal properties of textiles. By understanding the underlying principles and employing various techniques, textile companies can optimize their products for optimal performance in a variety of applications. In the future, we can expect more innovative and sustainable textile solutions that prioritize energy efficiency and environmental sustainability.

随着科技的不断发展,纺织品行业也在不断进步,其中远红外技术作为新型功能材料,其在纺织品中的应用越来越广泛,为了确保纺织品的质量和性能,对其远红外性能进行测试是必不可少的,本篇将详细介绍纺织品远红外测试方法,并结合案例进行分析。

纺织品远红外测试方法

测试原理

纺织品远红外测试主要基于红外辐射测量技术,通过测量纺织品在特定波长范围内的辐射强度和辐射功率,来评估其远红外性能,具体测试方法包括红外辐射测量仪器的选择、样品准备、测试条件设定等步骤。

测试步骤

(1)样品准备:选择符合要求的纺织品样品,确保样品尺寸、厚度、材质等参数符合测试要求。

(2)仪器选择:根据测试需求选择合适的红外辐射测量仪器,如红外热像仪、红外光谱仪等。

(3)测试条件设定:设定测试环境,确保环境温度、湿度等参数稳定,避免外界因素干扰。

(4)测试过程:将样品置于红外辐射测量仪器中,按照仪器操作指南进行测试。

(5)数据分析:根据测量结果,对纺织品远红外性能进行评估和分析。

案例分析

以某品牌纺织品为例,对其远红外性能进行测试和分析。

案例背景

该品牌纺织品在市场上具有较高的知名度和口碑,其远红外性能得到了广泛认可,为了确保产品质量和性能,对该品牌纺织品进行了远红外测试。

测试过程

(1)仪器选择:选择红外热像仪进行测试。

(2)样品准备:选取符合要求的样品,确保样品尺寸、厚度、材质等参数符合要求。

(3)测试条件设定:设定测试环境,确保环境温度、湿度等参数稳定,对测试过程进行严格控制,确保测试结果的准确性。

(4)测试结果分析:根据红外辐射测量结果,对该品牌纺织品进行了远红外性能评估和分析,结果显示,该品牌纺织品具有较高的辐射强度和辐射功率,表明其远红外性能良好,该品牌还提供了详细的测试报告和数据图表,以便客户了解该品牌纺织品的远红外性能情况。

总结与展望

纺织品远红外测试方法对于保证纺织品的质量和性能具有重要意义,本篇介绍了纺织品远红外测试方法以及结合案例进行分析,还提出了未来纺织品远红外测试的发展趋势和方向。

纺织品远红外测试方法主要包括样品准备、仪器选择、测试条件设定和测试过程等步骤,在实际操作中,需要严格按照测试方法进行操作,以确保测试结果的准确性,还需要结合案例进行分析,以便更好地了解纺织品远红外性能情况,未来纺织品远红外测试的发展趋势是更加智能化和自动化,同时还需要加强国际合作和交流,共同推动纺织品行业的发展。

展望:

随着科技的不断进步和人们对纺织品性能要求的不断提高,纺织品远红外测试方法将会越来越完善和成熟,未来纺织品行业将会更加注重产品质量和性能的检测和控制,同时也将会更加注重环保和可持续性发展,还需要加强国际合作和交流,共同推动纺织品行业的创新和发展。

Articles related to the knowledge points of this article:

How Much Can Textile Wholesale Generate Monthly?

The Story of Xian Xintianxiang Textile Wholesale in the西安市碑林区鑫天翔纺织品批发部