Understanding and Ensuring the Safety Standards of Industrial Textiles

: Understanding and Ensuring the Safety Standards of Industrial Textiles,Abstract:,Industrial textiles, as a crucial component of modern manufacturing, play a critical role in ensuring safety standards. This paper aims to explore the understanding and enforcement of safety standards for industrial textiles, highlighting the importance of adherence to these standards for the prevention of accidents and injuries. The discussion will cover the definition of safety standards, the identification of hazards in industrial textiles, and the implementation of measures to ensure compliance with these standards. Additionally, the paper will discuss the challenges faced by industries in meeting these safety standards and propose solutions to overcome them. The ultimate goal is to promote safer working environments for employees and minimize the risk of accidents and injuries.

Introduction: In today's fast-paced industrial landscape, textiles play a crucial role in various sectors such as construction, healthcare, and apparel. The safety of these products is paramount not only for their intended use but also for the well-being of consumers and workers alike. This talk will explore the key standards that govern the production and use of industrial textiles, including the International Organization for Standardization (ISO) standards, and how they are implemented and monitored to ensure product safety. Additionally, we will look at some real-life cases where these standards have been put into practice and the outcomes.

I. Overview of Industrial Textiles and Their Applications Textiles are materials used in a wide range of industries, from building materials to medical equipment, and from sportswear to fashion trends. They are essential for creating functional and aesthetically pleasing products that meet specific requirements.

II. Understanding Industrial Textiles Safety Standards Safety standards define the minimum requirements for the quality and performance of industrial textiles. These standards aim to prevent accidents, injuries, and health hazards by ensuring that textiles meet certain criteria.

III. ISO Standards in the Industry ISO stands for International Organization for Standardization, an international organization that develops standards and guidelines for various industries. The ISO standard for textiles covers aspects like material properties, production processes, testing methods, and product certification. It is widely recognized globally and is often used as a benchmark for industry compliance.

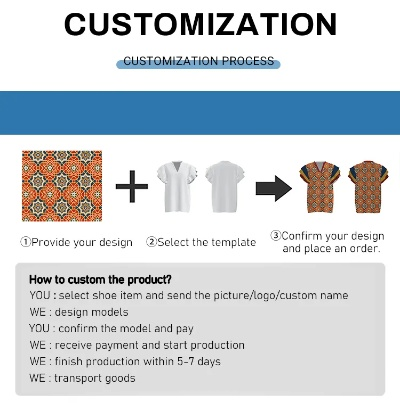

IV. Implementation and Monitoring of Safety Standards To ensure that safety standards are effectively implemented, companies must follow a systematic process. This includes setting up a quality management system (QMS), conducting regular audits, and implementing corrective actions when necessary. Companies also need to collaborate with regulatory bodies to monitor their compliance with safety standards.

V. Real-Life Case Studies Case Study 1: ISO 9001 Certification A textile company was certified under the ISO 9001 standard, which focuses on quality management systems. The company implemented a comprehensive QMS that included regular inspections, audits, and training sessions for employees. As a result, the company's products were consistently rated high in quality and safety.

Case Study 2: Implementing ISO 14644 for Medical Equipment A hospital supply chain involved in the production of medical equipment had to comply with ISO 14644 standards. The company implemented a rigorous testing protocol for each product before it was released to the market. This approach helped to reduce the risk of patient harm and ensure that the products met the highest standards of safety and efficacy.

VI. Challenges and Opportunities in Safe Textile Production While safety standards provide a framework for industry compliance, there can be challenges in achieving them. For instance, new technologies and materials may require additional testing and certification. Additionally, changes in regulations or shifts in consumer preferences can impact the need for updated safety standards. However, these challenges present opportunities for innovation and continuous improvement in the industry.

Conclusion: In conclusion, understanding and implementing safety standards for industrial textiles is crucial for ensuring the quality and safety of products. By following ISO standards and implementing a systematic process for compliance, companies can minimize risks and enhance their reputation in the marketplace. While challenges exist, they also present opportunities for continuous learning and growth within the industry.

随着纺织行业的快速发展,产业用纺织品作为重要的功能性材料,其安全标准问题日益受到关注,本篇旨在深入探讨产业用纺织品安全标准的相关内容,并结合实际案例进行说明。

产业用纺织品安全标准概述

安全标准的重要性

产业用纺织品作为直接接触人体皮肤的产品,其安全性直接关系到人们的健康和安全,制定严格的安全标准是保障产品质量和消费者权益的必要措施。

安全标准的内容

产业用纺织品安全标准主要包括原材料选择、产品性能、使用安全等方面的规定,具体包括但不限于纤维成分、有害物质限量、燃烧性能、抗过敏性能等要求。

案例分析

某知名品牌产业用纺织品安全标准案例

某知名品牌在产业用纺织品领域具有较高的知名度和口碑,其产品采用高品质原材料,经过严格的生产工艺流程,确保产品性能稳定可靠,该品牌严格遵守国家相关安全标准,确保产品安全无虞。

产业用纺织品安全问题曝光

某地区出现了一些产业用纺织品安全问题,涉及产品质量不合格、有害物质超标等问题,这给消费者带来了极大的安全隐患,也对企业的声誉造成了不良影响。

安全标准的具体要求

原材料选择

(1)环保无害:选用环保无害的原材料,不含有害物质。 (2)质量稳定:确保原材料来源可靠,质量稳定可靠。

产品性能

(1)耐热性能:产品应具有优良的耐热性能,能够承受高温环境。 (2)抗过敏性能:产品应具有抗过敏性能,避免皮肤过敏反应。

使用安全

(1)标识清晰:产品应有明确的标识,标明使用范围、注意事项等信息。 (2)安全认证:产品应通过相关安全认证,符合国家相关标准。

提高产业用纺织品安全标准的措施

加强监管力度,严格执行安全标准

政府和相关监管部门应加强对产业用纺织品企业的监管力度,严格执行国家相关安全标准,确保产品质量和安全,加强对企业的培训和指导,提高企业的安全生产意识和能力。

提高企业自律意识,加强质量管理体系建设

企业应加强自律意识,建立健全的质量管理体系,确保产品质量和安全,加强原材料采购、生产过程控制等方面的管理,提高产品的质量和稳定性。

产业用纺织品安全标准是保障产品质量和消费者权益的重要措施,企业应严格遵守国家相关安全标准,加强监管力度和自律意识,提高产品质量和安全性,政府和相关监管部门也应加强监管力度,促进产业用纺织品行业的健康发展。

Articles related to the knowledge points of this article: