The Role of Technology in Textile Industry Production

Technology plays a crucial role in the textile industry, transforming the manufacturing process and enhancing product quality. Advances in automation, machine learning, and data analytics have significantly improved efficiency and reduced costs. The integration of robotics and artificial intelligence has revolutionized the textile industry by automating complex tasks, increasing production speed, and minimizing human errors. Additionally, advanced materials and design tools have enabled designers to create innovative textiles with unique textures, patterns, and colors. The use of digital printing technology has also expanded the textile industry's capabilities, allowing for high-resolution prints and eco-friendly dyes. Overall, technology is driving innovation and shaping the future of the textile industry, offering endless possibilities for growth and development.

In the textile industry, technology plays a crucial role in enhancing production efficiency, quality control, and product innovation. This article will discuss the various technologies employed by textile enterprises to improve their operations and meet market demands.

Technology Impact on Production Efficiency

One of the most significant benefits of technology is its impact on production efficiency. Textile enterprises use advanced machinery and automation systems to increase output while minimizing waste. For example, the use of computer-controlled machines reduces manual errors and enhances consistency in production. Additionally, robotics are now being used in textile mills to perform repetitive tasks, freeing up human workers for more complex and creative work.

Table 1: Examples of Advanced Machinery and Automation Systems Employed by Textile Enterprises | Technology | Application | Benefits | |------------|------------|------------| | Computer-Controlled Machines | Increased output, reduced waste | Improved consistency | | Robotics | Repetitive tasks | Frees up human workers for more complex work |

Technology in Quality Control

Quality control is another area where technology has made a significant impact. Textile enterprises use advanced testing equipment, such as X-ray machines, to inspect fabrics for defects before they are sent to the final customer. This not only ensures better quality but also reduces the risk of defects being passed on to the final product.

Table 2: Examples of Advanced Testing Equipment Employed by Textile Enterprises | Technology | Application | Benefits | |------------|------------|------------| | X-ray Machines | Inspection of fabrics | Ensures better quality and reduces defect risks |

Technology in Product Innovation

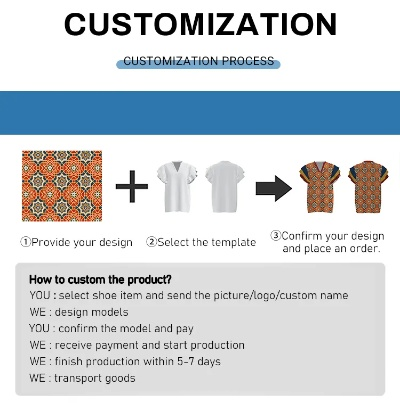

Finally, technology has played a vital role in product innovation. Textile enterprises are increasingly using digital printing and 3D printing technologies to create unique and personalized products. These technologies enable designers to experiment with new colors, patterns, and textures without the limitations of traditional manufacturing methods.

Table 3: Examples of Digital Printing and 3D Printing Technologies Employed by Textile Enterprises | Technology | Application | Benefits | |------------|------------|------------| | Digital Printing | Creates unique and personalized products | Allows designers to experiment with new designs | | 3D Printing | Creates intricate shapes and designs | Can produce complex shapes that are difficult to replicate with traditional methods |

Case Study: Technological Advancements at Pima Cotton Mills

Pima Cotton Mills is a leading textile enterprise in the United States that has been utilizing cutting-edge technology to enhance its production processes. One notable example is their implementation of an automated weaving system that uses machine learning algorithms to optimize weaving speed and quality. This system has resulted in increased productivity and reduced labor costs, while maintaining consistent quality standards.

Another example is Pima Cotton Mills' use of drone technology for crop monitoring. By using drones equipped with high-resolution cameras and sensors, farmers can monitor the growth of cotton plants in real-time, ensuring optimal crop yields and reducing the risk of crop damage due to pests or weather conditions.

Overall, technology has revolutionized the textile industry, enabling enterprises to operate more efficiently, produce higher quality products, and innovate new designs. As technology continues to advance, it will undoubtedly play an even greater role in shaping the future of the textile industry.

纺织品企业生产技术概述

随着全球纺织行业的快速发展,纺织品企业对于生产技术的要求也越来越高,本文将围绕纺织品企业生产技术展开讨论,包括生产流程、关键技术以及案例分析。

生产流程

原料采集与预处理

纺织品企业首先需要从原料供应商处采购高质量的原料,并进行必要的预处理,如清洗、整理等。

织造工艺

织造工艺是纺织品生产的关键环节,现代纺织企业采用先进的织造技术,如数字化织造、智能织造等,以提高生产效率和产品质量。

染整加工

染整加工是纺织品加工的重要环节,包括染色、印花、整理等工艺,现代染整技术可以实现高色牢度、高环保性能等目标。

关键技术

数字化织造技术

数字化织造技术是现代纺织企业的重要生产技术之一,它可以通过计算机辅助设计(CAD)软件进行精确的织造设计,实现高效的生产,数字化织造技术还可以提高生产效率和产品质量,降低生产成本。

智能纺织技术

智能纺织技术是一种基于物联网、大数据、人工智能等技术的纺织生产技术,它可以实现智能化生产,提高生产过程的自动化和智能化水平,智能纺织技术还可以提高生产效率和质量,降低人力资源成本。

环保纺织技术

随着环保意识的提高,纺织品企业需要采用环保纺织技术,实现绿色生产,采用生物降解材料、循环利用材料等环保材料,减少废物的产生和环境污染,采用节能减排的生产工艺和技术,降低生产成本和能源消耗。

案例分析

以某知名纺织品企业为例,其采用先进的数字化织造技术,实现了高效的生产和质量控制,该企业采用了先进的CAD软件进行精确的织造设计,实现了高效的生产流程,该企业还采用了智能质检系统,实现了产品质量的有效控制,该企业还注重环保和节能减排,采用环保材料和节能减排的生产工艺,实现了绿色生产。

纺织品企业生产技术是影响产品质量和竞争力的关键因素之一,随着科技的不断发展和应用,纺织品企业需要不断更新生产技术和设备,提高生产效率和产品质量,纺织品企业还需要注重环保和节能减排,实现绿色生产和可持续发展,通过采用先进的数字化织造技术、智能纺织技术和环保纺织技术等关键技术,以及具体的案例分析,我们可以更好地了解纺织品企业生产技术的发展趋势和方向。

Articles related to the knowledge points of this article:

Industrial Printing Textile Testing Standards

Discovering the Gem of Global Trade Locating Big Feng Textiles Building