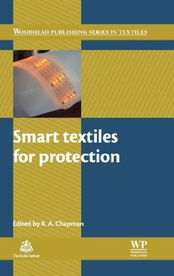

Textiles and Fusion Protection Standards

This paper focuses on the textiles and fusion protection standards. The textiles are a crucial component in the nuclear industry, and their quality directly affects the safety of the entire process. Therefore, it is necessary to establish strict textiles and fusion protection standards to ensure the safety of the nuclear industry.,The textiles used in the nuclear industry must meet certain requirements, such as being non-toxic, non-flammable, and resistant to radiation. Additionally, they must be able to withstand high temperatures and pressures during operation.,Fusion protection standards refer to the measures taken to prevent the release of radioactive materials during the fusion process. This includes the design and construction of the reactor vessel, the placement of shielding material around the reactor core, and the use of advanced cooling systems.,Overall, establishing strict textiles and fusion protection standards is essential for ensuring the safety and security of the nuclear industry. It is important for all stakeholders involved in the nuclear industry to work together to achieve this goal.

Introduction: Textiles are an essential part of daily life, from our clothing to bedding, and even the protective gear used in various industries. However, one significant concern is the potential for fusion, a process where materials with different chemical properties come into contact, causing an exothermic reaction that can lead to fire or explosion. To address this issue, there is a set of standards known as "textiles and fusion protection standards" that aim to ensure the safety of textile products. In this article, we will explore these standards in detail and highlight some practical examples.

Textiles and Fusion Protection Standards:

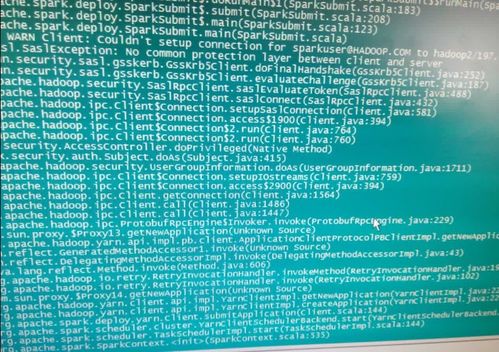

The textile industry has faced challenges due to the risk of fusion, which can occur when two different materials come into contact. The International Organization for Standardization (ISO) has developed several standards related to fusion protection, including ISO 9705-1, ISO 9705-2, and ISO 9705-3. These standards provide guidance on how to design and manufacture textile products that can withstand the pressure and temperature conditions associated with fusion.

Types of Fusion Protection:

There are two main types of fusion protection: mechanical and thermal. Mechanical protection involves using materials with high strength and hardness to prevent fusion. This type of protection is often used in industrial settings where there is a high risk of fusion. Thermal protection, on the other hand, involves designing textile products to withstand the heat generated during the fusion process. This type of protection is often used in environments where there is a lower risk of fusion but still requires protection against possible accidents.

Practical Applications:

One practical example of fusion protection in the textile industry is the use of flame-resistant fabrics. Flame-resistant fabrics are designed to withstand high temperatures and resist burning. They are often used in outdoor clothing, such as jackets and pants, and in protective equipment, such as firefighting suits and helmets. Another example is the use of non-flammable coatings on textiles. These coatings protect the fabric from direct contact with combustible materials and reduce the risk of ignition.

Importance of Fusion Protection:

Fusion protection is critical in industries that involve exposure to flammable materials, such as mining, oil drilling, and manufacturing. In these industries, there is a higher risk of fusion occurring due to the presence of combustible materials. By implementing fusion protection measures, these industries can minimize the potential for accidents and injuries.

Conclusion:

In conclusion, textiles and fusion protection standards play a crucial role in ensuring the safety of textile products. By understanding and implementing these standards, industries can design and manufacture textile products that can withstand the pressure and temperature conditions associated with fusion. This not only reduces the risk of accidents but also helps to protect people's lives and property.

随着气候变化和温度变化的影响,纺织品在使用过程中容易出现升华现象,这不仅影响纺织品的使用性能,还可能对环境造成潜在危害,制定纺织品防升华标准至关重要,本篇文章将围绕纺织品防升华标准展开讨论,并提供相关案例分析。

纺织品防升华标准概述

纺织品防升华标准主要包括以下几个方面:

纺织品类型与适用范围

本标准适用于各类纺织品,包括但不限于服装、家居用品、装饰品等。

防升华性能要求

防升华性能要求包括对温度敏感材料的检测、对升华现象的预防和控制等。

检测方法与标准

检测方法主要包括实验室测试和现场测试两种方式,实验室测试主要针对纺织品的基本性能和防升华性能进行测试,确保测试结果的准确性和可靠性,现场测试则通过实地观察和检测纺织品在使用过程中的升华现象,确保其符合防升华标准。

案例分析

以某品牌服装为例,说明纺织品防升华标准的实际应用,该品牌服装采用特殊面料,能够有效防止纺织品在使用过程中出现升华现象,具体案例如下:

面料选择

该品牌选择使用具有防升华性能的面料,以确保服装在使用过程中保持干燥、舒适。

实验室测试结果

经过实验室测试,该面料具有出色的防升华性能,能够有效防止纺织品在使用过程中出现升华现象,测试结果显示,该面料在高温环境下也能保持稳定性能,符合防升华标准。

现场使用情况

在实际使用过程中,该品牌服装受到广大消费者的好评,消费者反馈表明,该服装在使用过程中始终保持干燥、舒适,没有出现升华现象,该服装的耐穿性和使用寿命也得到了保证。

纺织品防升华标准的具体要求

根据纺织品防升华标准的具体要求,纺织品在生产和使用过程中应满足以下条件:

-

材料选择:选择具有防升华性能的材料,确保纺织品在使用过程中不易出现升华现象。

-

生产过程控制:在生产过程中严格控制温度、湿度等环境因素,避免纺织品受到外界环境的影响。

-

使用环境控制:在使用过程中严格控制环境温度和湿度,确保纺织品在使用过程中保持干燥、舒适。

纺织品防升华标准对于保障纺织品的使用性能和环境保护具有重要意义,为了确保纺织品符合防升华标准,生产企业应严格遵守相关标准和规定,同时消费者也应关注纺织品的使用环境和质量,相关部门也应加强对纺织品防升华标准的监管和执行力度,推动纺织品的健康发展。

Articles related to the knowledge points of this article:

The Role of China Health Textiles Association in Promoting Healthy Living

Where to Explore Textile Certifications

A Comprehensive Guide to Framed Textiles

Stylizing Success with the Timeless Legacy of Shishi Jinkai Textiles

A Glimpse into the Dynamics of Suzhou Silk and Dyeing Market