Understanding the Varieties of Textile Coatings

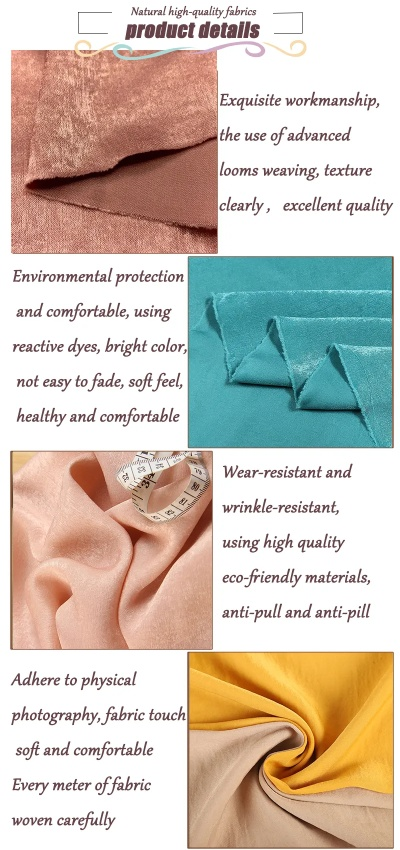

: Exploring the Diverse Nature of Textile Coatings,In the realm of textile engineering, the application of coatings is a critical aspect that enhances the performance and durability of fabrics. This paper aims to provide a comprehensive overview of the various types of textile coatings, their characteristics, and the methods used for their application. The discussion will delve into the classification of textile coatings based on their function, material composition, and manufacturing process.,The first category includes protective coatings designed to protect textiles from environmental factors such as moisture, dust, and sunlight. These coatings are typically made of plastics or elastomers and have a high resistance to wear and tear.,Next, we explore functional coatings that impart specific properties to textiles, such as flame retardancy, antimicrobial activity, or color retention. These coatings are often applied through spray or dip techniques and can be formulated with natural or synthetic materials.,Lastly, we examine decorative coatings that add aesthetic appeal to textiles. These coatings can be applied in a variety of ways, including brush painting, silkscreen printing, or embroidery. They can also be used to create patterns or designs that complement the overall look of the fabric.,In conclusion, understanding the diverse nature of textile coatings is crucial for tailoring them to meet specific needs and requirements. By exploring the different types and methods of application, we can develop more effective and durable textile products that meet the demands of modern society.

Introduction: Textile coatings are an important component in enhancing the performance and appearance of textile products. They provide protection against wear and tear, improve durability, and enhance colorfastness. In this article, we will explore the different types of textile coatings and their applications. We will also provide an example to illustrate how these coatings can be used in real-world scenarios.

Types of Textile Coatings:

-

Waterproof Coatings: These coatings are designed to prevent moisture from seeping through the fabric. They are commonly used in sportswear and outdoor clothing to protect the fabric from water damage.

-

Anti-static Coatings: These coatings help to reduce static electricity buildup on fabrics, which can cause irritation for some individuals. They are often used in clothing and upholstery.

-

UV Resistant Coatings: These coatings protect textiles from ultraviolet radiation, which can cause fading and discoloration over time. They are commonly used in outdoor clothing and upholstery.

-

Heat Stabilized Coatings: These coatings provide a protective layer that resists heat damage during washing and drying. They are often used in apparel and home textiles.

-

Eco-friendly Coatings: These coatings are made from natural or sustainable materials, such as plant-based oils or recycled plastics. They are designed to reduce environmental impact and promote sustainability.

Example: One example of a waterproof coating is the Teflon® brand. This coating is widely used in sportswear, including jackets, pants, and hats. It provides excellent water resistance and helps to prevent moisture from seeping through the fabric. Another example is the anti-static coating, which is found in many electronics and furniture products. It helps to reduce static electricity buildup, making them more comfortable to handle.

Conclusion: Textile coatings play a crucial role in enhancing the performance and appearance of textile products. By understanding the different types of coatings available, you can choose the right one for your needs. Whether you need a waterproof coating for outdoor clothing or an eco-friendly coating for home textiles, there is a coating out there that will meet your requirements. So why not take advantage of the many benefits that these coatings offer?

今天我们来探讨一下纺织品涂层的分类及其应用,在纺织行业中,涂层技术发挥着至关重要的作用,它们不仅提高了纺织品的性能,还为消费者提供了更多选择,本文将通过表格和案例说明,详细介绍纺织品涂层的分类以及实际应用。

纺织品涂层的分类

按功能分类

(1)防污涂层

防污涂层主要用于防止油污、污渍等污染物的附着,根据不同的防污技术,可分为光亮防污涂层、抗油涂层等。

(2)耐磨涂层

耐磨涂层主要用于提高纺织品的耐磨性能,包括金属氧化物涂层、陶瓷涂层等。

(3)抗菌涂层

抗菌涂层主要用于防止细菌滋生,提高纺织品的卫生性能,常见的抗菌涂层材料包括银、铜等金属纳米材料。

按材料分类

(1)塑料涂层

塑料涂层是一种以塑料为主要材料的涂层,具有优良的耐久性和防水性能,常见的塑料涂层材料包括聚乙烯、聚丙烯等。

(2)纤维涂层

纤维涂层主要应用于纤维材料的表面处理,如织物防水、防油等,常见的纤维涂层材料包括合成纤维、天然纤维等。

按工艺分类

(1)粉末涂料

粉末涂料是一种以粉末形态存在的涂料,具有优良的耐久性和装饰性,适用于各种纺织品表面处理。

(2)液体涂料

液体涂料是一种常见的涂料类型,适用于各种纺织品,具有较好的施工性能和装饰性。

案例说明

防污涂层应用案例

某品牌的一款防水涤纶面料采用了防污涂层技术,可以有效防止油污和污渍的附着,该面料采用了特殊的防污涂层材料,具有优异的防污性能和耐久性,受到了消费者的广泛好评。

耐磨涂层应用案例

某公司的一款耐磨织物采用了耐磨涂层技术,提高了纺织品的耐磨性能,该织物采用了金属氧化物涂层材料,具有较高的耐磨性能和防水性能,适用于各种工业和商业用途。

纺织品涂层的分类多种多样,根据不同的需求和应用场景,可以选择不同的涂层材料和技术,在纺织行业中,涂层技术的应用越来越广泛,为消费者提供了更多的选择,随着科技的不断进步,新型的涂料技术和工艺也不断涌现,为纺织品涂层的未来发展注入了新的活力。

Articles related to the knowledge points of this article:

Textile Industry in Global Perspective

Quality in Knitwear:A Comprehensive Guide to Assessing and Understanding