Advanced Textile Surface Durability Techniques

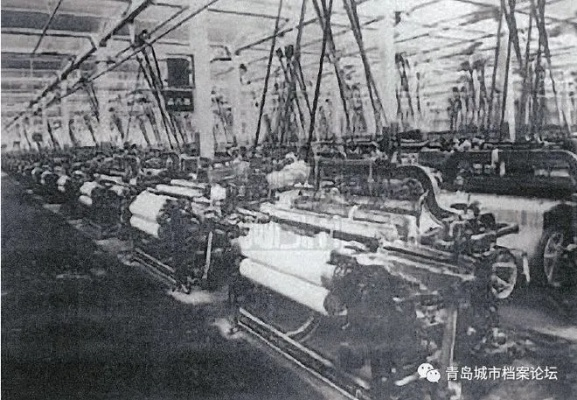

Advanced Textile Surface Durability Techniques:,In the textile industry, surface durability is a crucial factor that determines the longevity of garments and other textile products. This paper presents an overview of advanced techniques used to enhance the surface durability of textiles. These techniques include chemical treatments such as dyeing, finishing, and coating, physical treatments such as heat setting and steaming, and mechanical treatments such as compression and ironing. By implementing these techniques, textile manufacturers can create durable and long-lasting fabrics that withstand wear and tear, stains, and other environmental factors. Additionally, this paper discusses the importance of selecting appropriate materials and finishes for specific applications, as well as the potential risks associated with using certain chemicals or processes. Overall, the advancements in textile surface durability techniques have made it possible to produce high-quality textiles that meet the needs of consumers and businesses around the world.

Introduction: Textiles are an integral part of our daily lives, from clothing to home furnishings. However, they often face wear and tear due to various factors such as washing, friction, and exposure to harsh environments. To ensure that textiles remain durable and attractive for a longer period, surface treatment methods have been developed. In this article, we will explore some of the most effective techniques for enhancing the durability of textile surfaces. We will also provide an overview of their effectiveness and potential applications in different industries.

-

Chemical Treatments: Chemical treatments involve applying chemicals to the textile surface to improve its resistance to wear and tear. Some common chemicals used for this purpose include alkaline solutions, acids, and surfactants. These treatments can enhance the texture, color, and overall appearance of the textile. For example, a chemical treatment called "bleaching" can remove any stains or impurities on the fabric, making it more resistant to soiling and fading.

-

Mechanical Treatments: Mechanical treatments involve using tools or machines to physically alter the surface of the textile. Some examples of mechanical treatments include scouring, sandblasting, and embossing. These treatments can create a smoother, more textured surface that is less prone to wear and tear. For instance, embossing involves pressing a pattern into the fabric, which creates a raised texture that can add visual interest and make the fabric more durable.

-

UV Sterilization: UV sterilization involves exposing textiles to ultraviolet light to kill bacteria and viruses. This treatment can extend the lifespan of textiles by preventing bacterial growth and mold development. For example, many medical gowns and protective gear are treated with UV sterilization to prevent cross-contamination during surgery.

-

Electrostatic Coating: Electrostatic coating involves applying a thin layer of polymers or resins to the textile surface using an electrostatic process. This coating provides a barrier against moisture, dirt, and dust, making the textile more resistant to wear and tear. An example of this technique is the use of polyurethane coatings on carpets and upholstery fabrics.

-

Thermoplastic Coatings: Thermoplastic coatings are applied to textile surfaces using heat and pressure. These coatings are flexible and can be easily applied to a wide range of textiles, including cotton, wool, and synthetic materials. They provide a protective layer that can resist scratches, abrasions, and other forms of damage. A popular example of this technique is the use of polyvinyl chloride (PVC) coatings on outdoor furniture and sports equipment.

-

Nanotechnology Applications: Nanotechnology has revolutionized the field of textile surface treatments by introducing new materials and technologies that offer enhanced durability and functionality. For example, nanoparticles can be incorporated into the textile structure to increase its strength and resistance to wear and tear. Similarly, nanocoatings can be applied to textile surfaces to provide antibacterial, antifungal, and antimicrobial properties.

Case Study: One example of the effectiveness of these techniques can be seen in the case of military uniforms. Military uniforms require high levels of durability and resistance to wear and tear. To meet these requirements, military uniforms are often treated with chemical treatments such as bleaching and dyeing. Additionally, they may be subjected to mechanical treatments such as scouring and embossing to create a smoother, more textured surface. Finally, they may be treated with UV sterilization to prevent cross-contamination during operations.

Conclusion: Textile surface treatment methods play a crucial role in extending the lifespan of textiles and ensuring their durability in various applications. From chemical treatments to mechanical treatments, from UV sterilization to electrostatic coatings, there are numerous techniques available to achieve this goal. As technology continues to advance, new applications and innovations in textile surface treatment will continue to emerge, further enhancing the durability and functionality of textiles.

纺织品表面耐磨处理方法概述

随着纺织工业的不断发展,耐磨性能已成为衡量纺织品质量的重要指标之一,为了提升纺织品的耐磨性能,我们采用一系列的耐磨处理方法,本篇将详细介绍这些处理方法及其应用案例。

耐磨处理方法介绍

化学处理

化学处理是提高纺织品耐磨性能的一种常见方法,通过在纺织品表面涂覆耐磨涂层,可以显著提高其耐磨性能,常用的化学处理方法包括涂层制备、涂层固化、表面处理等步骤,使用纳米技术制备的耐磨涂层,具有优异的耐磨性能和抗腐蚀性,广泛应用于各种纺织品的表面处理中。

表面处理技术

表面处理技术包括表面预处理、表面涂覆和表面改性等,表面预处理是提高纺织品耐磨性能的基础,通过使用各种表面处理设备和技术,如等离子处理、激光处理、电解处理等,可以有效地去除纺织品表面的杂质和污染物,提高其表面粗糙度和亲水性,从而增强其耐磨性能。

案例说明

纳米涂层处理

某纺织公司采用纳米涂层处理技术,对纺织品进行表面耐磨处理,经过处理后,该纺织品的耐磨性能得到了显著提升,纳米涂层具有优异的耐磨性能和抗腐蚀性,能够有效抵抗磨损和腐蚀,延长纺织品的使用寿命,该公司的纳米涂层处理方法得到了广泛的应用,并取得了良好的效果。

特种纤维处理

某公司采用特种纤维处理技术,对高强度纤维织物进行表面处理,通过使用特殊的工艺和设备,该高强度纤维织物表面变得更加光滑和坚硬,提高了其耐磨性能,这种处理方法适用于各种高强度需求的纺织品,如运动服装、工业用布等。

表格补充说明

以下是关于纺织品表面耐磨处理方法的一些表格补充说明:

| 耐磨处理方法 | 描述 | 应用案例 |

|---|---|---|

| 化学处理 | 在纺织品表面涂覆耐磨涂层 | 提高耐磨性能和抗腐蚀性 |

| 表面预处理 | 使用各种表面处理设备和技术去除杂质和污染物 | 提高表面粗糙度和亲水性 |

| 纳米涂层处理 | 采用纳米技术制备的耐磨涂层 | 提高耐磨性能和抗腐蚀性,广泛应用于各种纺织品的表面处理中 |

| 特种纤维处理 | 使用特种纤维进行表面处理 | 提高高强度纤维织物耐磨性能 |

纺织品表面耐磨处理方法多种多样,包括化学处理、表面预处理、特种纤维处理等,不同的处理方法适用于不同类型的纺织品,可以有效地提高纺织品的耐磨性能和抗腐蚀性,在实际应用中,需要根据纺织品的特点和需求选择合适的处理方法,随着科技的不断进步,新的耐磨处理方法也不断涌现,为纺织品的耐磨性能提升提供了更多的可能性。

Articles related to the knowledge points of this article:

The Elegant Threads of杏林康信家用纺织品

Empowering Textiles:Exploring the Fabric of Success in Cottons Heartland

The Standards and Measurements of Textile Fiber Density

蠡县束束纺织品店 A Journey through Quality Textiles and Innovation

Transforming Fashion with Fabrics:An Insight into Fuzhou Fengqinyuan Textiles