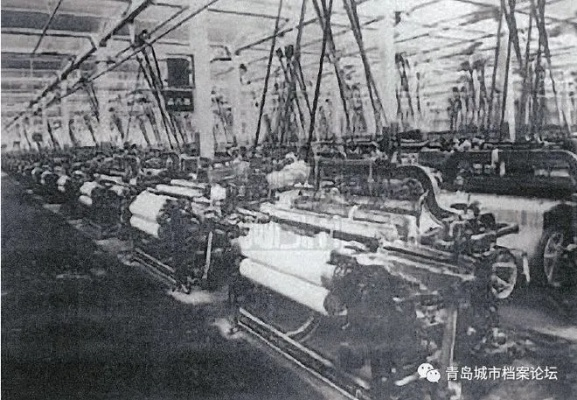

Understanding the Timeframe for Textile Product Inspections

: Understanding the Timeframe for Textile Product Inspections,In the realm of textile product inspections, time is a critical factor that must be taken into account to ensure quality and safety. The duration for which products are inspected can significantly impact the overall efficiency and effectiveness of these inspections. This paper aims to explore the significance of understanding the timeframe for textile product inspections and how it affects the quality control process.,The examination of the inspection timeline is crucial in determining the level of scrutiny required for each product. It allows for an accurate assessment of the quality and conformity of the textile materials, thereby ensuring that they meet the standards set forth by regulatory bodies. The appropriate timeframe for inspections should take into consideration the type of textile product being inspected, its complexity, and the potential risks associated with its use.,The duration of inspections can also affect the cost-effectiveness of the quality control process. Prolonged inspections may result in higher costs due to additional resources required, while shorter inspections may not provide sufficient assurance of product quality. Therefore, it is essential to strike a balance between the time required for inspections and the overall cost of the quality control process.,In conclusion, understanding the timeframe for textile product inspections is crucial in ensuring quality and safety. The duration of inspections should be carefully considered to determine the level of scrutiny required for each product and the cost-effectiveness of the quality control process. By doing so, we can improve the overall efficiency of our inspections and ensure that textile products meet the highest standards of quality and safety.

In the realm of quality control, ensuring that products meet industry standards is paramount. One critical aspect of this process is the timeline for conducting product inspections, particularly in the textile industry where quality assurance is a cornerstone. This discussion aims to delve into the duration and methods for keeping textile samples during inspections and how they are used to ensure product compliance.

Timeframe for Textile Product Inspections

The timeframe for textile product inspections can vary significantly depending on various factors such as the nature of the product, the regulatory requirements, and the efficiency of the inspection process. Here's a breakdown of some common scenarios:

-

Short-term Inspections (<30 Days): For products with short shelf lives or high turnover rates, inspections might be conducted within a few days to ensure immediate product release without compromising quality. This could involve spot checks or quick visual inspections.

-

Medium-term Inspections (30-90 Days): For medium-term inspections, samples may be retained for up to 90 days, allowing for a more thorough evaluation of the product's quality and potential defects. This period allows for detailed testing and analysis to ensure that the product meets the required standards.

-

Long-term Inspections (>90 Days): For longer-term inspections, samples may be kept for up to 180 days or even longer, depending on the specific regulations and industry practices. These inspections often involve comprehensive testing, including laboratory analyses, to ensure that the product meets all applicable standards and guidelines.

Methods for Keeping Textile Samples During Inspections

When it comes to storing textile samples during inspections, there are several methods that can be employed to maintain their integrity and ensure accurate results. Some common techniques include:

-

Temperature Control: Ensure that samples are stored at controlled temperatures to prevent any degradation or deterioration that could affect their quality. This is particularly important for materials that are sensitive to temperature changes, such as fabrics or yarns.

-

Humidity Management: Monitor the humidity levels in the storage area to prevent moisture from causing damage to the samples. Moisture can lead to mold growth, which can compromise the integrity of the sample and impact its quality assessment.

-

Avoiding Excessive Light: Exposure to excessive light can cause fading or discoloration in textile samples, affecting their appearance and potentially affecting their quality. It's essential to keep samples away from direct sunlight and artificial lighting sources.

-

Preservation Techniques: Use preservative solutions or packaging materials designed specifically for textile samples to maintain their condition throughout the inspection process. This helps to minimize any damage that could occur during transportation or storage.

Case Study: Textile Product Compliance Through Inspection Timeframes

One example of how timeframes for textile product inspections can impact compliance is seen in the case of a major apparel company that produces high-quality sportswear. The company implemented a strict policy for inspecting its fabric samples, ensuring that they were tested for strength, tear resistance, and colorfastness.

The company decided to retain samples for up to 90 days during inspections, allowing for a thorough analysis of each batch of fabric. This allowed the company to identify any defects early on, before they had a chance to affect the final product. By implementing this timeframe, the company was able to improve its product quality and ensure compliance with regulatory standards.

Conclusion

In conclusion, understanding the timeframe for textile product inspections is crucial for maintaining product quality and ensuring compliance with regulatory requirements. By carefully selecting the appropriate inspection timeframe and employing effective storage methods, companies can minimize the risk of defects and maintain their reputation for producing high-quality products.

背景信息

关于纺织品抽检保留时间的讨论引起了广泛关注,为了明确纺织品抽检的保留期限,我们有必要对相关法规和实际情况进行深入了解。

保留时间概述

根据相关法规和实际情况,纺织品抽检的保留时间通常取决于多个因素,包括抽检频率、检验标准、检验流程等,纺织品抽检的保留时间可以是一个月、一季度或更长的时间,具体的保留时间长度还需根据具体情况而定。

保留时间的具体案例分析

以下是一个具体的案例说明,以供参考:

某地区纺织品抽检保留时间案例

该地区近期进行了纺织品抽检工作,根据以往经验和相关法规,纺织品抽检的保留时间通常为一个月,在这次抽检中,抽取了一定数量的样品进行检验,以确保纺织品的质量符合相关标准和要求,经过检验,发现部分样品存在轻微质量问题,因此需要进行进一步的调查和处理,经过调查和处理后,这些样品将按照保留时间继续进行后续处理和监测。

保留时间的注意事项

在纺织品抽检过程中,需要注意以下几点:

- 确保抽检的公正性和科学性,严格按照相关法规和标准进行抽检。

- 保留期限内需要确保样品的质量符合相关标准和要求,避免出现质量问题。

- 对于需要进一步调查和处理的情况,需要按照相关规定进行处理和监测。

纺织品抽检的保留时间是一个复杂的问题,需要考虑多个因素,根据实际情况和法规要求,纺织品抽检的保留时间可以是一个月、一季度或更长的时间,在保留期限内,需要确保样品的质量符合相关标准和要求,同时还需要注意保留期限内的其他事项。

为了更好地保障纺织品的质量和安全,建议相关部门加强监管力度,提高检验效率和质量水平,也需要加强宣传和教育,提高公众对纺织品质量的认识和意识,对于纺织品抽检的保留期限和具体处理方式,也需要根据实际情况进行灵活处理。

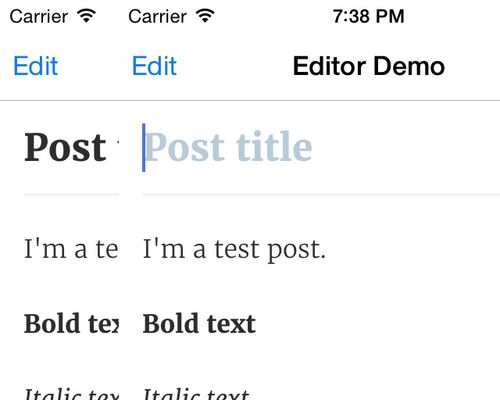

补充说明(表格形式)

以下是关于纺织品抽检保留时间的补充说明表格:

| 指标 | 描述 | 示例数据 |

|---|---|---|

| 抽检频率 | 每月一次 | 根据实际情况而定 |

| 检验标准 | 符合相关国家和行业标准 | 根据实际样品情况而定 |

| 保留期限 | 一个月至一年 | 根据具体情况而定 |

| 其他注意事项 | 确保样品质量符合要求、避免出现质量问题等 | 根据实际情况而定 |

表格仅供参考,实际保留时间长度还需根据具体情况而定,在纺织品抽检过程中,相关部门需要加强监管力度,提高检验效率和质量水平,确保纺织品的质量和安全,也需要加强宣传和教育,提高公众对纺织品质量的认识和意识。

Articles related to the knowledge points of this article:

Exploring the Ten Top Textiles of Stone Lions An Illustrative Journey