The Role of a Textile Sampler in the Fashion Industry

The textile sampler is a crucial tool in the fashion industry, enabling designers to create and test new fabrics and patterns before they are mass produced. This process involves carefully selecting and preparing samples of various materials, which can then be used to evaluate their performance in different environments and under different conditions. The sampler's ability to replicate the texture and color of the finished product allows designers to make informed decisions about the best fabrics and colors to use in their designs. Additionally, the sampler's ability to produce accurate measurements and calculations ensures that each fabric and pattern meets the exact specifications required for the final garment. Overall, the textile sampler plays a critical role in ensuring that fashion designers have the tools they need to create high-quality, stylish clothing that meets the needs of their customers.

Introduction: In the world of fashion, textile samples play a crucial role in ensuring that designs are not only visually appealing but also practical and sustainable. As a textile sampler within a large-scale clothing manufacturer, my job is to ensure that every fabric used in our collections is of the highest quality and meets the standards set by our clients. This article will explore the responsibilities of a textile sampler, highlighting some of the challenges they face and how they overcome them.

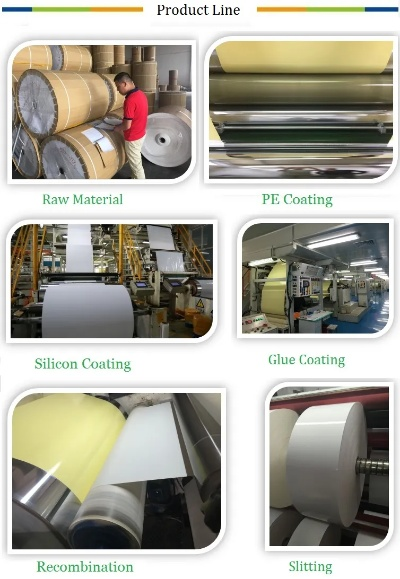

Responsibilities: As a textile sampler, my primary responsibility is to select and prepare fabric samples for our designers. This includes selecting fabrics that meet our specifications, such as color, texture, and durability, as well as ensuring that the samples are of high quality and consistent with our brand image. Additionally, I am responsible for managing and maintaining a vast array of fabric samples, ensuring that they are stored properly and accessible when needed.

Challenges: One of the biggest challenges facing textile samplers is the sheer volume of fabric samples available. With so many different types of fabrics and patterns, it can be difficult to keep track of which ones are in stock and which ones need to be ordered. Additionally, ensuring that all fabric samples meet our quality standards can be time-consuming and requires meticulous attention to detail.

Another challenge is working within tight deadlines. Designers often have limited time to develop new collections and must rely on textile samplers to provide them with the right fabrics at the right time. This means that samplers must be able to work quickly and efficiently to meet these demands.

Solutions: To address these challenges, we have implemented several solutions. Firstly, we have developed a system that allows us to easily manage and organize our fabric samples. This system uses barcodes and other identification methods to ensure that each fabric is accurately labeled and categorized. Additionally, we have invested in advanced technology, such as computerized cutting tables and automated fabric preparation machines, to streamline the fabric selection process.

In terms of meeting tight deadlines, we have established a dedicated team of samplers who work closely with designers to ensure that fabrics are ready for use when needed. We also prioritize our orders, ensuring that we only order the fabrics that are most critical to our designs. By doing this, we can minimize delays and ensure that our designers have access to the fabrics they need when they need them.

Case Study: One example of how a textile sampler can make a difference is the case of a major fashion brand that was struggling to find the right fabrics for their latest collection. The brand had a limited budget and was looking for fabrics that were both affordable and durable. Our textile sampler identified a few potential fabric suppliers who could meet these requirements and worked with them to secure samples that met the brand's specifications. These samples were then used by our designers to create a collection that was both stylish and functional.

Conclusion: As a textile sampler, I am proud to play a vital role in the fashion industry. Through careful selection and management of fabric samples, we ensure that our clients receive only the best products. While there are certainly challenges to overcome, such as managing a vast array of fabrics and staying on top of tight deadlines, we have found ways to overcome these obstacles through innovation and collaboration. As the fashion industry continues to evolve, so too will our approach to textile sampling.

大家好,今天我想和大家分享一下关于纺织厂小样员的工作经历和心得,作为一名纺织厂的小样员,我们不仅需要掌握专业的纺织技术,还需要具备良好的沟通能力和团队合作精神,下面,我将通过英文案例说明和表格详细介绍小样员的工作内容和职责。 与职责

样品制作与测试

在纺织厂中,小样员的主要工作是负责制作样品并进行测试,他们需要熟悉各种纺织面料和辅料,能够根据客户的需求和标准制作出符合要求的样品,在测试阶段,小样员需要仔细检查样品的质量和性能,确保其符合客户的要求。

表格说明:

| 项目 | 描述 | 小样员职责 |

|---|---|---|

| 样品制作流程 | 设计样品图案、选择面料和辅料、进行缝制和整理 | 负责制作符合要求的样品,并进行质量检测 |

| 测试环节 | 对样品进行性能测试、外观检查等 | 确保样品的质量和性能符合客户要求 |

与其他部门沟通协作

作为纺织厂的小样员,我们还需要与生产部门、质量部门等其他部门进行密切的沟通与合作,我们需要了解生产进度、质量控制标准等信息,以便更好地完成样品制作和测试工作,我们还需要与供应商保持联系,确保原材料的质量和供应稳定性。

案例说明:

以某纺织厂为例,小样员在日常工作中需要与采购部门密切沟通,了解最新的原材料供应情况,他们还需要与生产部门保持密切联系,了解生产计划和进度,以便更好地安排样品制作工作,他们还需要与其他部门共同协作,确保样品的质量和性能符合客户要求。

案例分析

在某纺织厂中,小样员通过与供应商紧密合作,成功完成了多个重要样品的制作和测试工作,他们根据客户的需求和标准,选择了高质量的面料和辅料,并进行了精细的缝制和整理,在测试阶段,他们仔细检查了样品的质量和性能,确保其符合客户的要求,他们还与其他部门进行了密切的沟通与合作,确保了整个工作流程的高效性和准确性。

总结与展望

作为一名纺织厂的小样员,我们需要不断学习和提高自己的专业技能和沟通能力,我们还需要注重团队合作和协作精神的培养,在未来的工作中,我们还需要不断探索新的技术和方法,以提高样品制作和测试的效率和准确性,我们还需要注重样品的质量和性能,确保其符合客户的要求和标准。

作为纺织厂的小样员,我们需要不断提高自己的专业能力和沟通能力,注重团队合作和协作精神的培养,我们还需要不断探索新的技术和方法,提高样品制作和测试的效率和准确性,我们才能更好地完成工作任务,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article: