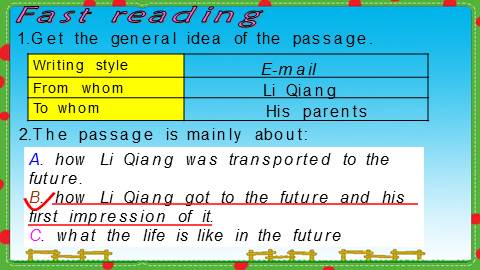

Understanding the Cost of Textiles Calcium Sulfate

: The Cost of Textiles Calcium Sulfate,Textile materials, such as cotton, wool, and polyester, are crucial components in the fashion industry. However, one significant cost associated with these materials is the use of calcium sulfate. This compound is commonly used as a thickening agent in textiles to improve their texture and appearance. In this study, we aim to explore the economic implications of using calcium sulfate in textile production.,The cost of calcium sulfate can vary depending on several factors, including the type of textile material, the amount of calcium sulfate used, and the manufacturing process. For example, the cost of producing a single piece of clothing made from a synthetic fabric containing 20% calcium sulfate may be significantly higher than that of a similar piece made from a natural fabric. Additionally, the cost of transportation and distribution may also contribute to the overall expense of using calcium sulfate in textile production.,In conclusion, understanding the costs associated with using calcium sulfate in textile production is crucial for manufacturers looking to optimize their operations and reduce expenses. By analyzing the various factors that affect the cost of calcium sulfate, manufacturers can make informed decisions about how to incorporate this material into their products while maintaining profitability.

Introduction In the textile industry, calcium sulfate is a versatile additive that plays a crucial role in enhancing the properties of fabrics such as strength, flexibility, and moisture absorption. This mineral is widely used in the production of yarn, fabrics, and other textile products. The cost of calcium sulfate can significantly impact the overall profitability of a textile company, making it an important factor to consider when making purchasing decisions. In this article, we will explore the factors that influence the price of textiles' calcium sulfate and provide some practical examples to help you make informed decisions.

Factors Affecting the Price of Textiles' Calcium Sulfate

-

Supply and Demand: The price of calcium sulfate is determined by supply and demand in the market. When there is a surplus of calcium sulfate in the market, producers may lower their prices to attract more buyers. Conversely, when demand for calcium sulfate increases due to increased usage in new products or improved manufacturing processes, prices may rise.

-

Production Costs: The cost of production is a significant factor in determining the price of calcium sulfate. This includes raw material costs, energy expenses, labor costs, and transportation expenses. If these costs increase, the price of calcium sulfate will also increase.

-

Quality Standards: The quality of calcium sulfate affects its price. High-quality calcium sulfate with better performance characteristics, such as higher strength and better moisture absorption, may command a higher price. However, if the quality standard is not met, the price may be lowered to ensure customer satisfaction.

-

Taxes and Duties: International trade involves taxes and duties on imported goods. These fees can add to the overall cost of calcium sulfate, which may affect the final price at the end of the transaction.

-

Exchange Rates: The exchange rate between different currencies can also affect the price of calcium sulfate. If the currency of the supplier is weaker than the currency of the buyer, the price may be lower for the buyer.

-

Economic Conditions: Economic conditions, such as inflation, interest rates, and consumer spending, can also influence the price of calcium sulfate. During times of economic growth, consumers may be willing to pay more for high-quality products, leading to higher prices.

-

Regulatory Policies: Government policies related to environmental protection, safety standards, and taxation can also impact the price of calcium sulfate. For example, stricter regulations on waste disposal can increase the cost of producing and disposing of calcium sulfate.

Practical Examples of Textiles' Calcium Sulfate Prices

Let's take a look at some real-world examples to illustrate how the factors affecting the price of textiles' calcium sulfate work in practice.

Example 1: Increased Demand for Textiles' Calcium Sulfate In the United States, there was a surge in demand for textiles' calcium sulfate during the COVID-19 pandemic. As a result, suppliers had to increase their production capacity and raise their prices to meet the growing demand. This led to a significant increase in the price of calcium sulfate for many textile companies.

Example 2: Lower Supply and Increased Production Costs In China, a textile company experienced a decrease in supply of textiles' calcium sulfate due to a natural disaster that disrupted the local mining operations. As a result, the company had to purchase the calcium sulfate from abroad at a higher price due to increased transportation costs and higher raw material prices.

Example 3: High-Quality Textiles with Better Moisture Absorption A textile company in Europe introduced a new line of high-quality clothing made with textiles' calcium sulfate that had superior moisture absorption properties. The company priced the product higher than traditional textiles due to the improved performance characteristics of the calcium sulfate. However, this move attracted a loyal customer base who were willing to pay a premium for the improved comfort and durability of the garments.

Conclusion The cost of textiles' calcium sulfate is influenced by various factors, including supply and demand, production costs, quality standards, taxes and duties, exchange rates, economic conditions, and regulatory policies. By understanding these factors and analyzing real-world examples, you can make more informed decisions about your purchasing decisions and manage your budget effectively.

大家好,今天我们来聊聊纺织品硫酸钙的价格,硫酸钙是一种重要的纺织原料,广泛应用于各种纺织品中,随着市场需求的不断变化,硫酸钙的价格也受到广泛关注。

硫酸钙市场概述

硫酸钙市场主要由供应量、需求量、原材料价格、生产成本等因素构成,在国内外市场上,硫酸钙主要来源于化工原料生产厂家和纺织企业,随着全球经济的不断发展和纺织行业的不断进步,硫酸钙的需求量也在不断增加。

硫酸钙价格影响因素

- 原料价格:硫酸钙的主要原料是硫酸钙矿物,其价格受到国内外市场供需关系的影响,当市场需求增加时,硫酸钙矿山的开采量也会相应增加,从而影响硫酸钙的价格。

- 生产成本:生产成本是影响硫酸钙价格的重要因素之一,包括原材料采购成本、生产过程中的能耗、设备折旧等成本都会影响硫酸钙的价格。

- 政策法规:政策法规也会对硫酸钙价格产生影响,环保政策、关税政策等都会对硫酸钙的生产和销售产生影响。

案例分析

以某地区为例,近年来硫酸钙的价格呈现上涨趋势,该地区硫酸钙矿山的开采量有所增加,同时生产成本也有所上升,当地政府出台了一系列环保政策,鼓励企业采用环保生产方式,这也影响了硫酸钙的价格。

硫酸钙价格趋势预测

根据市场调研和数据分析,预计未来硫酸钙的价格将继续上涨,随着全球经济的不断发展和纺织行业的不断进步,硫酸钙的需求量将继续增加;环保政策等政策法规的出台也将对硫酸钙价格产生一定影响。

建议与展望

针对硫酸钙市场,建议纺织企业加强与供应商的沟通与合作,及时了解市场动态和原材料价格变化情况;企业也应关注政策法规的变化,采取相应的应对措施,企业还可以通过技术创新和优化生产流程等方式降低生产成本,提高产品质量和竞争力。

硫酸钙作为一种重要的纺织原料,其价格受到多种因素的影响,在未来的发展中,硫酸钙的价格将继续上涨,纺织企业需要密切关注市场动态和原材料价格变化情况,采取相应的应对措施,以应对市场的变化,政府和企业也应该加强合作与交流,共同推动纺织行业的发展。

Articles related to the knowledge points of this article:

Textile Seam Flaw Detection:A Case Study

Detecting and Reducing Formaldehyde Exposure in Textile Products

Navigating the Landscape of Textile New Fabric Trends