The Porter Textile Factory:A Journey Through the World of Textiles

Introduction:

Welcome to the fascinating world of textiles, where every fabric is a story waiting to be told. Today, I'm taking you on a journey to the Porter Textile Factory, a place where creativity meets craftsmanship, and tradition meets innovation. Let's dive into the details of this remarkable factory and see how it has shaped the industry we all rely on.

Porter Textile Factory: A Brief History

The Porter Textile Factory was established in 1903, marking the beginning of a legacy that spanned over a century. Originally founded as a small workshop, the Porter Textile Factory grew into a leading manufacturer of high-quality textiles. Over the years, the factory expanded its operations, employing hundreds of skilled workers and becoming a hub for textile innovations.

Today, Porter Textile Factory stands as a testament to the dedication and hard work of its employees. With a rich history and a strong sense of community, the factory continues to produce quality products that meet the needs of customers around the world. In this article, we will explore the various aspects of the Porter Textile Factory, from its production processes to its commitment to sustainability.

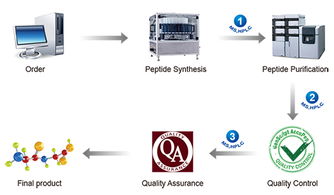

Production Processes:

At the heart of any successful textile factory lies its production processes. At Porter Textile Factory, these processes are meticulously designed to ensure the highest quality output. Here are some of the key steps involved in the production process:

-

Preparation: Before starting the actual manufacturing process, raw materials are carefully selected and prepared. This includes selecting the right yarn, fibers, and dyes, which are then mixed together to create the final product.

-

Weaving: Once the raw materials are ready, they are woven into fabric using specialized machinery. The weaving process involves interlacing threads to create a three-dimensional structure that gives strength and durability to the finished product.

-

Dyeing: After the weaving process, the fabric undergoes dyeing. This involves applying dyes to the fabric, which changes its color and pattern. The dyeing process can be done manually or through automated machines, depending on the complexity of the design.

-

Sizing and finishing: Once the fabric is dyed, it is size-dyed and then subjected to various finishing processes such as steaming, pressing, and finishing. These processes help to enhance the texture and appearance of the fabric while making it more resistant to wear and tear.

-

Packaging: Finally, the finished product is packaged in sturdy boxes or bags, depending on its intended use. This ensures that the product reaches its destination safely and in good condition.

Sustainability:

In today's world, sustainability has become an essential aspect of any industry. At Porter Textile Factory, sustainability is not just a trend but a core value that guides every decision made by the company. Here are some ways in which Porter Textile Factory practices sustainability:

-

Energy Efficiency: The factory uses energy-efficient lighting and machinery, reducing electricity consumption and minimizing waste.

-

Waste Management: Porter Textile Factory has implemented recycling programs and waste reduction strategies to minimize the amount of waste generated.

-

Eco-friendly Production: The factory uses eco-friendly dyes and chemicals, which are safer for both workers and the environment.

-

Recycling Programs: The factory has partnered with local recycling companies to recycle old fabric scraps, reducing the need for new raw materials.

-

Community Involvement: Porter Textile Factory actively supports local communities by providing job opportunities and funding initiatives that benefit the surrounding area.

Case Study:

One example of how Porter Textile Factory has contributed to sustainability is its partnership with a local community-based organization called "Green Hearts." Green Hearts works towards promoting sustainable farming practices in the region, using locally sourced materials for their products. As a result, Porter Textile Factory has started sourcing yarn and fibers from local farmers, supporting sustainable agriculture and reducing carbon emissions.

Conclusion:

In conclusion, Porter Textile Factory is more than just a factory; it is a symbol of innovation, craftsmanship, and sustainability. From its rich history to its commitment to sustainability, Porter Textile Factory has left an indelible mark on the textile industry. By embracing sustainability and promoting local communities, Porter Textile Factory has demonstrated that there is a balance between profit and responsibility that can be achieved through responsible business practices. So next time you walk down the streets of our city, remember that behind every beautiful piece of clothing or fabric is a story of passion, craftsmanship, and sustainability. Thank you for joining me on this journey through the world of textiles at Porter Textile Factory.

埠子纺织厂概述

埠子纺织厂位于一个美丽的乡村地区,以其精湛的纺织工艺和丰富的产品种类而闻名,该厂专注于各种纺织品的生产,包括但不限于棉布、丝绸、麻布等,这里汇聚了众多熟练的工人和先进的设备,为当地居民和国内外客户提供优质的产品和服务。

生产工艺与设备介绍

生产工艺:

埠子纺织厂采用先进的生产工艺,注重产品质量和环保,在生产过程中,严格控制原材料的质量和数量,采用环保型染料和助剂,确保产品绿色、健康、安全,该厂还注重技术创新,不断引进先进的生产设备和技术,提高生产效率和产品质量。

设备介绍:

埠子纺织厂拥有各种先进的纺织设备,包括但不限于织布机、印花机、烘干机、染色机等,这些设备不仅保证了生产的稳定性和效率,还提高了产品的质量和档次,该厂还注重设备的维护和保养,确保设备的长期稳定运行。

产品案例分析

产品种类丰富:

埠子纺织厂的产品种类繁多,涵盖了各种不同的纺织品,棉布是该厂的主要产品之一,具有透气、吸湿、柔软舒适等特点,深受消费者喜爱,该厂还生产丝绸、麻布等高档纺织品,具有优雅、高贵、舒适等特点。

案例说明:

以某次订单为例,埠子纺织厂成功生产了一批高质量的棉布产品,该批产品采用了先进的生产工艺和设备,保证了产品的质量和档次,在订单交付后,客户对该批产品的质量非常满意,表示该厂的产品不仅符合他们的要求,还提供了优质的服务,该厂还注重产品的环保和可持续性,采用了环保型染料和助剂,确保产品的绿色、健康、安全。

企业文化与员工情况

企业文化:

埠子纺织厂注重企业文化建设,倡导团队合作精神和创新精神,该厂鼓励员工积极参与企业活动,提高自身素质和能力,该厂还注重员工的福利待遇和发展空间,为员工提供良好的工作环境和发展机会。

员工情况:

埠子纺织厂的员工队伍非常强大,他们都是经过严格选拔和培训的熟练工人,该厂注重员工的培训和技能提升,为员工提供各种培训和学习机会,该厂还注重员工的福利待遇和社会福利,为员工提供良好的生活环境和健康保障。

未来展望与建议

未来展望:

埠子纺织厂将继续秉承“质量第一、客户至上”的经营理念,不断提高生产效率和产品质量,该厂还将不断引进先进的技术和设备,提高生产能力和技术水平,埠子纺织厂还将注重产品的环保和可持续性,推动企业可持续发展。

建议:

为了促进埠子纺织厂的持续发展,我们建议该厂加强与国内外客户的沟通和合作,提高市场竞争力,该厂还可以加强员工的培训和技能提升,提高员工素质和能力,埠子纺织厂还可以加强环保和可持续性方面的投入和宣传,提高企业的社会形象和声誉。

Articles related to the knowledge points of this article:

Strategies for Effective Management in a Textile Factory

The 22-Year-Old Textile Factory:A Journey Through Youth and Potential