A Comprehensive Overview of Textile Testing Schemes

This paper provides a comprehensive overview of textile testing schemes, covering various types of tests that are essential for assessing the quality and performance of textile products. The discussion includes mechanical properties such as tensile strength, elongation, and tear strength, as well as thermal properties like heat resistance and flame retardancy. Additionally, it covers chemical resistance to chemicals, dyeability, and colorfastness. The paper also discusses methods for measuring these properties, including instrumental techniques like tensile testing, calorimetry, and spectrophotometry, as well as non-instrumental methods like visual inspection and sensory evaluation. Finally, the paper outlines the regulatory requirements for textile testing, highlighting the importance of compliance with international standards such as ISO and ASTM. Overall, this paper aims to provide a thorough understanding of the different types of textile testing schemes and their applications in the industry.

Introduction Textiles are an integral part of our lives, from clothing and household items to industrial materials. To ensure that textile products meet the standards set by industry, regulatory bodies, and consumer expectations, rigorous testing is essential. This guide outlines a comprehensive test scheme for evaluating the quality and performance of textiles. We will discuss various types of tests, including mechanical properties, durability, colorfastness, and environmental impact. Additionally, we will provide case studies to illustrate how these tests can be applied in real-world scenarios.

Mechanical Properties Testing Mechanical properties refer to the strength, flexibility, and resistance to deformation of textiles. These properties are crucial for determining their suitability for specific applications.

- Tensile Testing: This test measures the breaking force required to stretch a sample. It evaluates the fabric's elongation and resilience under tension.

- Strain Testing: This method determines the maximum strain that the fabric can withstand before breaking. It provides insight into the fabric's elasticity and ability to recover its original shape after being stretched.

- Burst Testing: This test simulates the bursting pressure of a garment when worn by a person. It assesses the fabric's resistance to tearing and puncturing.

- Tear Testing: This test measures the force required to tear a sample of fabric. It evaluates the fabric's durability and ability to resist damage during wear and tear.

Durability Testing Durability is another critical aspect of textile testing. It refers to the ability of a fabric to resist wear, tear, and other forms of damage over time.

- Wash Testing: This test simulates the washing process by subjecting fabric samples to high temperatures and detergents. It evaluates the fabric's resistance to fading, pilling, and shrinkage.

- Dyeing Testing: This test assesses the fabric's resistance to dye bleeding and transfer during dyeing processes. It ensures that the colors remain consistent and bright throughout the product.

- Stress Testing: This method measures the fabric's resistance to compression, stretching, and bending. It evaluates the fabric's ability to maintain its shape and integrity under extreme conditions.

Colorfastness Testing Colorfastness is crucial for ensuring that textile products look vibrant and uniform even after multiple washes.

- CIE Lab* Colorimetric System: This system uses light measurements to determine the color intensity and hue of fabrics. It enables accurate assessment of color fastness over time.

- Hunter Color Scale: This scale evaluates the color saturation, lightness, and hue of fabrics. It helps identify any changes in color during the lifespan of the product.

- ISO 105-C02: This standard specifies methods for measuring color fastness using different lighting conditions and viewing angles. It ensures that color evaluations are consistent across different environments.

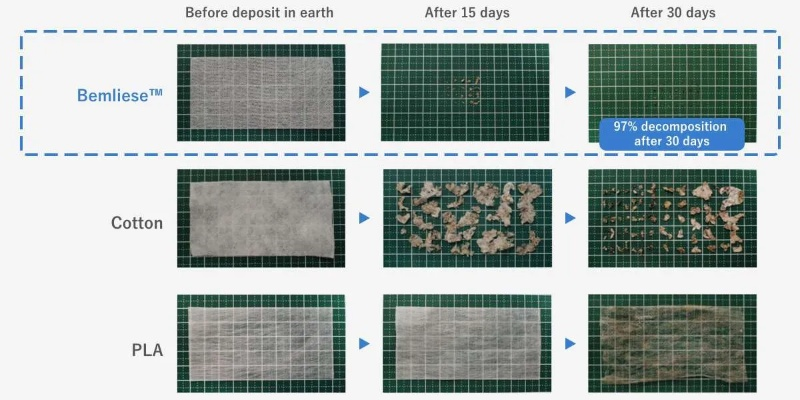

Environmental Impact Testing As awareness about sustainability grows, it becomes increasingly important to evaluate the environmental impact of textile products.

- Eco-Labeling: This certification system assigns eco-labels to textile products based on their manufacturing processes and waste management practices. It promotes responsible sourcing and production.

- Life Cycle Assessment (LCA): This method evaluates the environmental impact of a textile product from raw material extraction to disposal. It identifies potential areas for improvement and encourages sustainable practices.

- Recycling Rate: This metric measures the percentage of textile products that can be recycled or reused after being disposed of. High recycling rates indicate lower environmental impact.

Case Study: Textile Product Development Let's consider a hypothetical scenario where a fashion brand is developing a new line of denim jeans. The company has decided to incorporate sustainable practices into their manufacturing process to appeal to environmentally conscious consumers.

- Mechanical Properties Testing: The company conducts tensile testing and burst testing on the denim fabric to ensure it meets the required strength and durability standards. They also perform wash testing to ensure that the jeans retain their vibrant colors after multiple washes.

- Durability Testing: The company conducts stress testing on the denim jeans to ensure they withstand heavy use and tearing. They also perform dyeing testing to ensure that the colors do not fade or bleed during wear and tear.

- Colorfastness Testing: The company uses the CIE Lab* Colorimetric System to evaluate the color fastness of the denim jeans over time. They also perform eco-labeling to ensure that the manufacturing process aligns with sustainable practices.

- Environmental Impact Testing: The company conducts LCA analysis to evaluate the environmental impact of the denim jeans manufacturing process. They also track the recycling rate of the fabric to ensure that it can be reused or recycled effectively.

Conclusion Textile testing is an essential component of ensuring that textile products meet industry standards and consumer expectations. By implementing a comprehensive test scheme that includes mechanical properties, durability, colorfastness, and environmental impact testing, companies can develop products that are both functional and sustainable. Incorporating eco-labeling and LCA analysis can further enhance the sustainability of textile products while promoting responsible sourcing practices.

Articles related to the knowledge points of this article:

A Global Fabrics Revolution The Untold Story of Qi Da Textiles

The Art of Fabrics:A Journey through the World of帆里纺织品

The Art of Textiles:Exploring the World of Meikai Textiles